Composition for metal surface treatment

A metal surface treatment and composition technology, applied in the field of metal surface treatment compositions, can solve the problems of inability to obtain corrosion resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

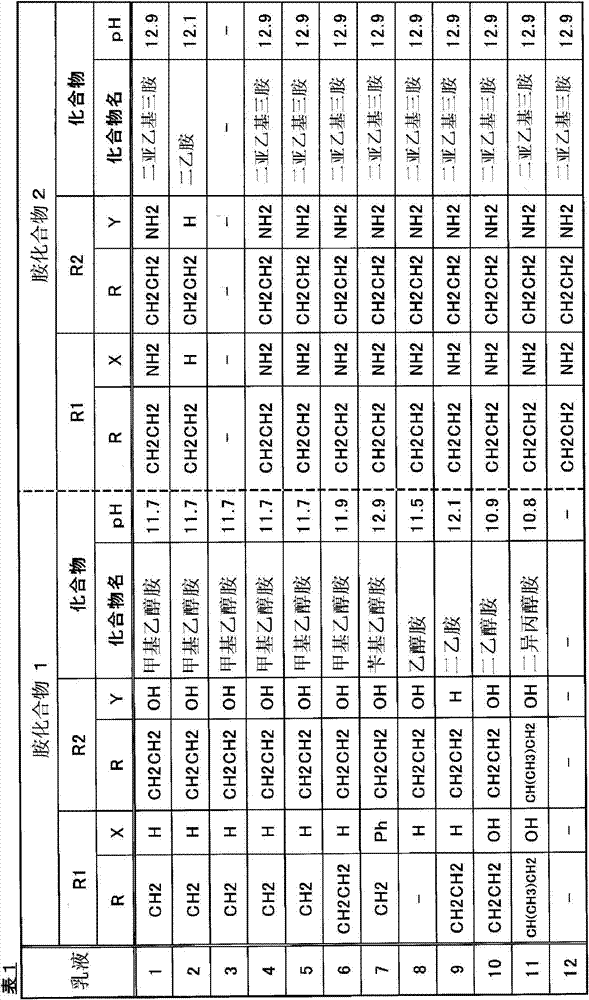

[0106] *The preparation method of the amide of bisphenol A type modified epoxy resin

[0107] First, predetermined amounts of modified resin (B), epoxy resin (C), and bisphenol (D) are mixed and heated and stirred. The heating temperature is preferably 70 to 100°C. After each raw material is dissolved, a catalyst is added, and the heating temperature is raised to carry out synthesis. Catalysts generally use tertiary amines such as dimethylbenzylamine. Usually the synthesis temperature is controlled at 120°C to 150°C.

[0108] By adjusting the synthesis temperature and time, an epoxy resin having a predetermined epoxy equivalent can be synthesized. The epoxy equivalent was calculated according to the epoxy equivalent measurement prescribed in JIS K7236. The epoxy equivalent at this time is preferably 800-10000, more preferably 800-5000, and most preferably 800-3000. When the epoxy equivalent is larger, the emulsion stability tends to decrease at the time of emulsion prepar...

preparation example 1

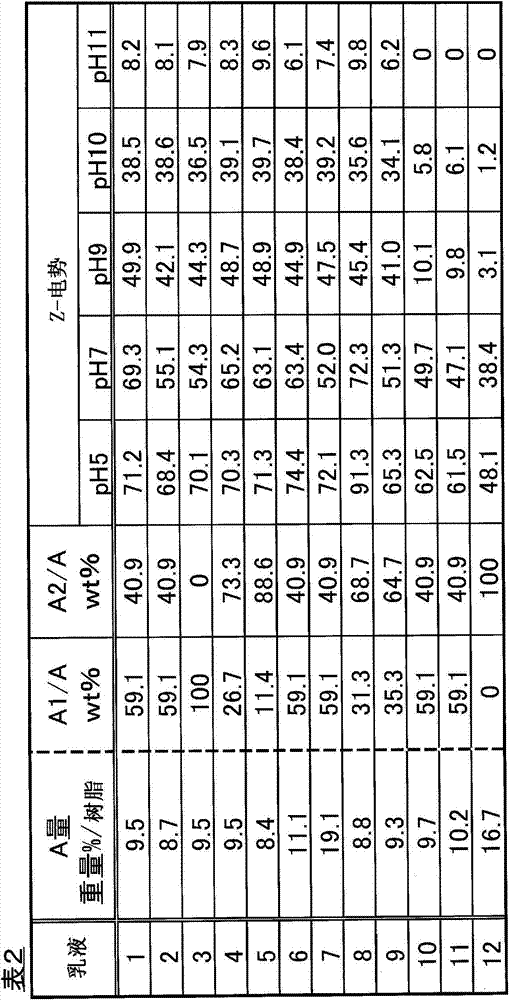

[0144] Epoxy resin #828 (manufactured by Mitsubishi Chemical Corporation, epoxy equivalent: 180): 114.0 g, polycaprolactone di Alcohol Placcel208 (made by Daicel Chemical Co., Ltd.): 41.5 g, bisphenol A: 45.6 g, 0.1 g of dimethylbenzylamine, reacted at 130 degreeC until epoxy equivalent became 1000. After completion of the reaction, 55.5 g of butyl cellosolve was added, and 12.5 g of methylethanolamine and 8.6 g of ketimide of diethylenetriamine were further added, and reacted at 90° C. for 2 hours. Added blocked isocyanate: 105.5g, dibutyltin diacetate: 3.2g, acetic acid 5.4g, after stirring evenly, 578.1g of deionized water was dripped in for about 1 hour while vigorously stirring to obtain a solid content concentration of 33%, A water-based resin emulsion (A1) having a zeta potential of 69.3 mV in an aqueous medium of pH 7 and a zeta potential of 8.2 mV in an aqueous medium of pH 11.

preparation example 2

[0146] Epoxy resin #828 (manufactured by Mitsubishi Chemical Corporation, epoxy equivalent: 180): 114.0 g, polycaprolactone di Alcohol Placcel208 (made by Daicel Chemical Co., Ltd.): 41.5 g, bisphenol A: 45.6 g, 0.1 g of dimethylbenzylamine, reacted at 130 degreeC until epoxy equivalent became 1000. After completion of the reaction, 55.5 g of butyl cellosolve was added, and 11.3 g of methylethanolamine and 7.8 g of diethylamine were further added, and reacted at 90° C. for 2 hours. Added blocked isocyanate: 105.5g, dibutyltin diacetate: 3.2g, acetic acid 5.4g, after stirring evenly, 578.1g of deionized water was dripped in for about 1 hour while vigorously stirring to obtain a solid content concentration of 33%, A water-based resin emulsion (A2) having a zeta potential of 55.1 mV in an aqueous medium of pH 7 and a zeta potential of 8.1 mV in an aqueous medium of pH 11.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com