Piezoelectric calcium phosphate cement composite material

A technology of calcium phosphate bone cement and composite material is applied in the field of bone cement solid phase powder and its preparation, piezoelectric calcium phosphate bone cement composite material, and can solve the problems of artificial bone repair materials lacking natural bone piezoelectricity and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

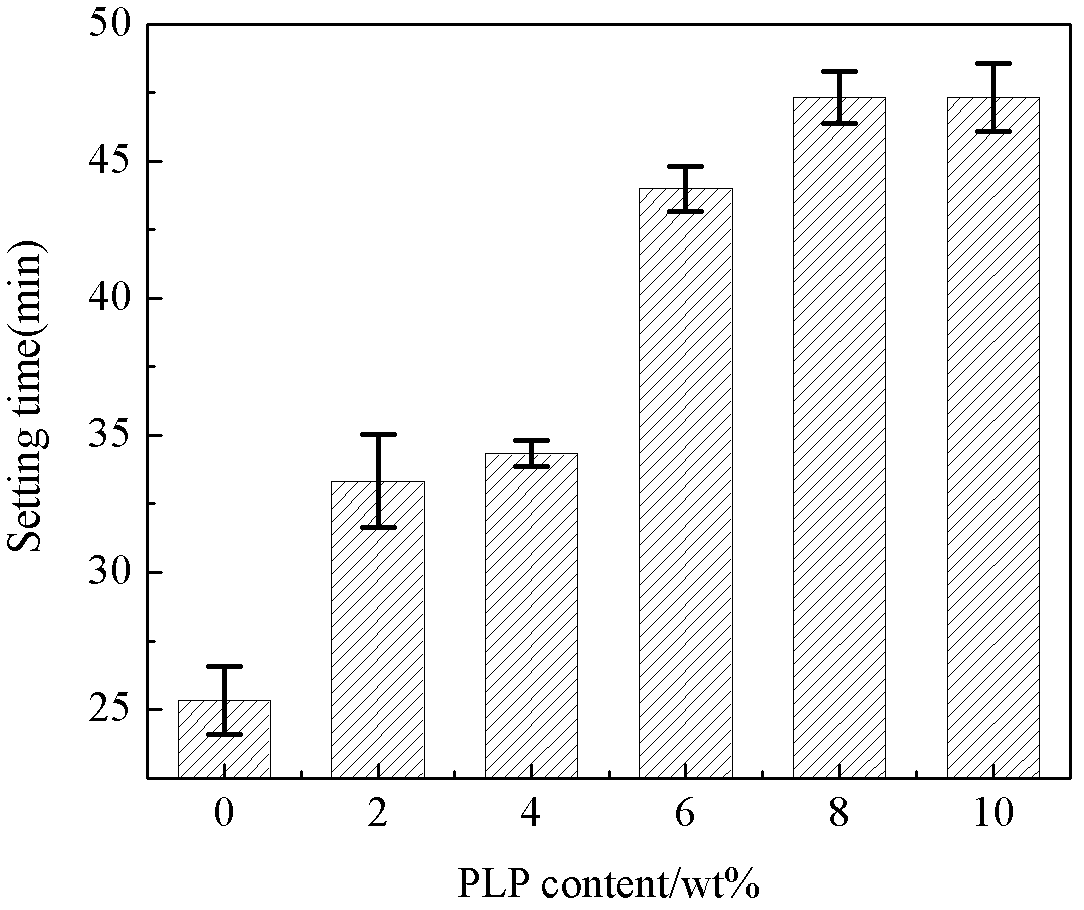

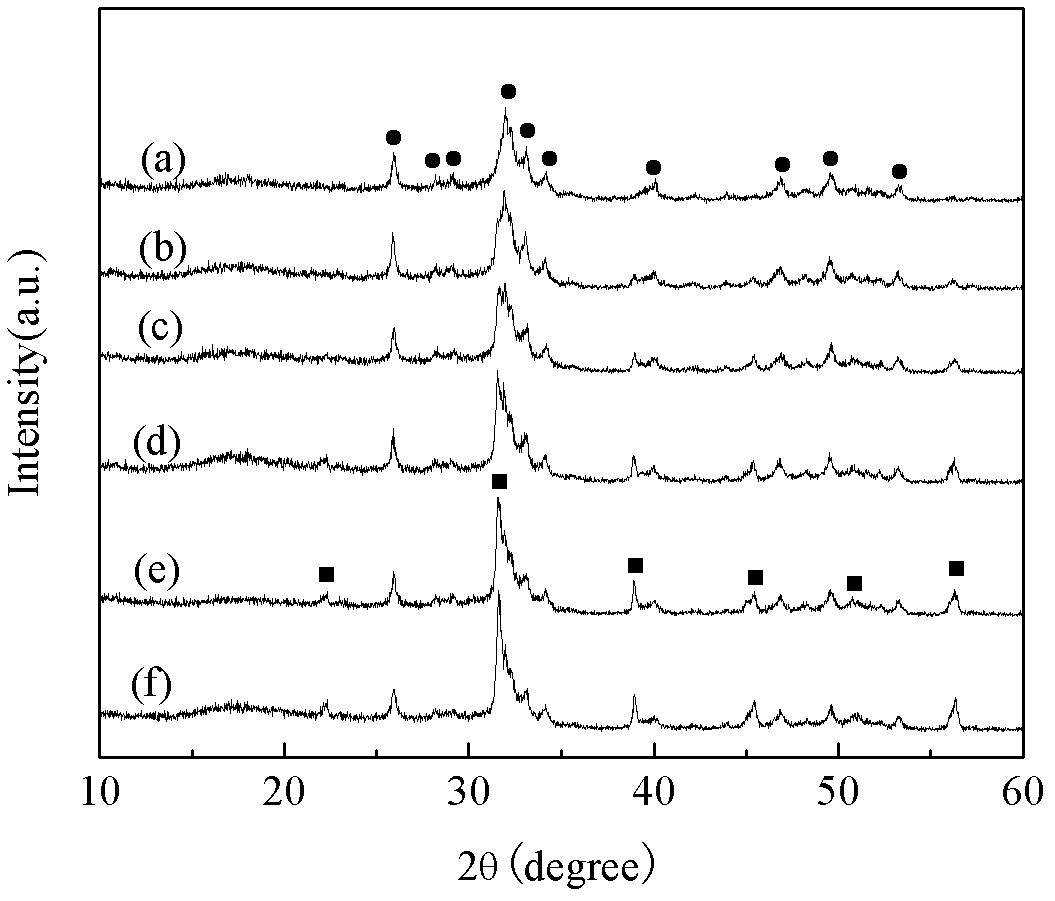

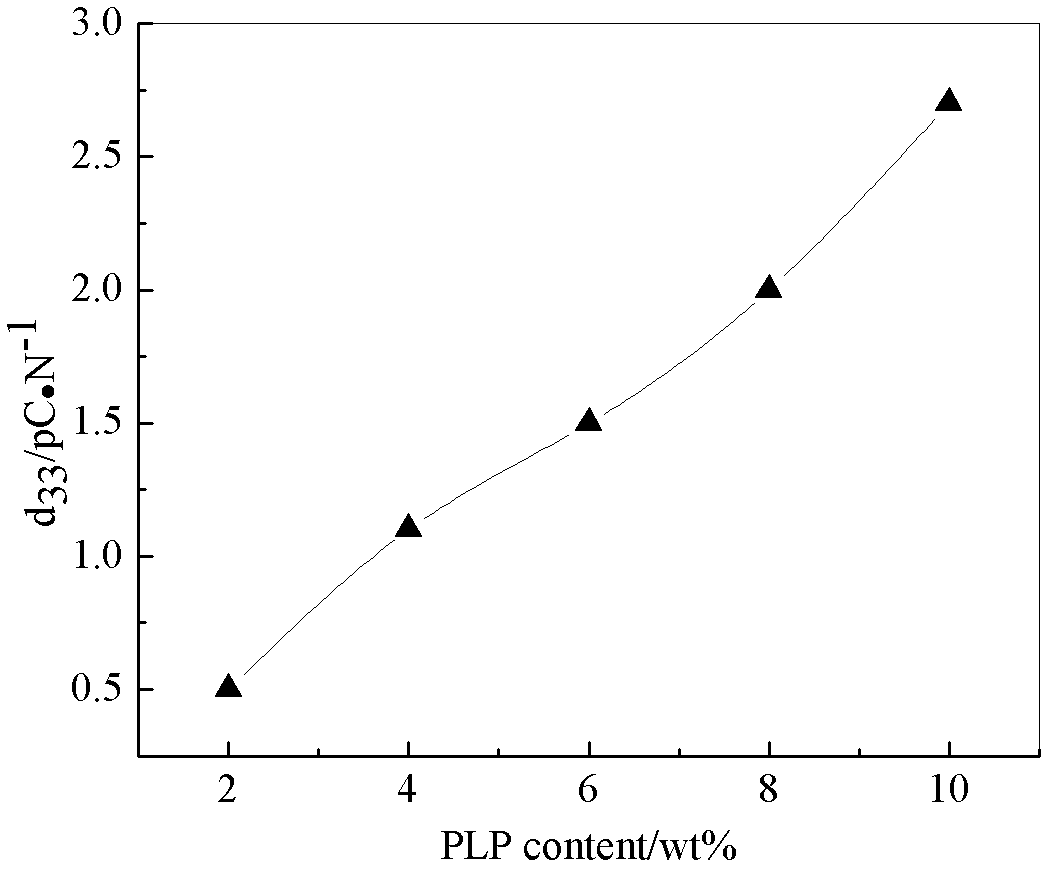

[0021] Disperse 0.12g of PLP (calcium titanate with an average particle size of 10nm) powder in ethanol, after stirring, add 5.88g of CPC powder (mixed powder of tetracalcium phosphate and calcium hydrogen phosphate) (average particle size of 15um), stir, and grind in a mortar. Dry at 80°C until constant weight, and grind into powder for later use.

[0022] Take 0.6g of PLP / CPC solid phase powder and mix evenly with phosphate buffer solution. The piezoelectric calcium phosphate bone cement slurry prepared after mixing evenly at a solid / liquid ratio of 3.0 g / mL was filled into a steel mold, and a pressure of 5 MPa was applied to remove air bubbles. % after curing for 2 hours and demoulding, and continuing curing for 3 days, a composite bone cement solidified body was obtained.

Embodiment 2

[0024] Disperse 0.24g of PLP (average particle size of 100nm barium titanate) powder in methanol, after stirring, add 5.76g of CPC powder (mixed powder of tetracalcium phosphate and calcium hydrogen phosphate) (average particle size of 15um), stir and mortar grinding, Dry at 90°C until constant weight, and grind into powder for later use.

[0025] Take 0.6g of PLP / CPC solid phase powder and mix evenly with simulated body fluid solution. The piezoelectric calcium phosphate bone cement prepared after mixing evenly at a solid / liquid ratio of 2 g / mL was filled into a steel mold, and a pressure of 15 MPa was applied to remove air bubbles. After curing for 2 hours and demoulding, continue curing for 1 day to obtain a composite bone cement solidified body.

Embodiment 3

[0027] Disperse 0.36g of PLP powder (average particle size 100nm calcium titanate) in dimethylformamide, after stirring, add 5.64g CPC powder (mixed powder of β-phase tricalcium phosphate and calcium dihydrogen phosphate) (average particle size 30um ), stirred, ground in a mortar, baked at 70°C until constant weight, and ground into powder for later use.

[0028] Take 0.6g of PLP / CPC solid phase powder and mix evenly with plasma. The piezoelectric calcium phosphate bone cement prepared after mixing evenly at a solid / liquid ratio of 1g / mL was filled into a steel mold, and a pressure of 20MPa was applied to remove air bubbles. After curing for 2 hours and demoulding, continue curing for 3 days to obtain a composite bone cement solidified body.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Piezoelectric strain constant | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com