Piezoelectric touch control film and piezoelectric touch display panel comprising same

A technology of touch film and piezoelectric film, applied in piezoelectric/electrostrictive/magnetostrictive devices, piezoelectric/electrostrictive device manufacturing/assembly, circuits, etc., can solve expensive, time-consuming, transparent low performance and other problems, to achieve the effect of precise and adjustable thickness, simple and fast method, and improved utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

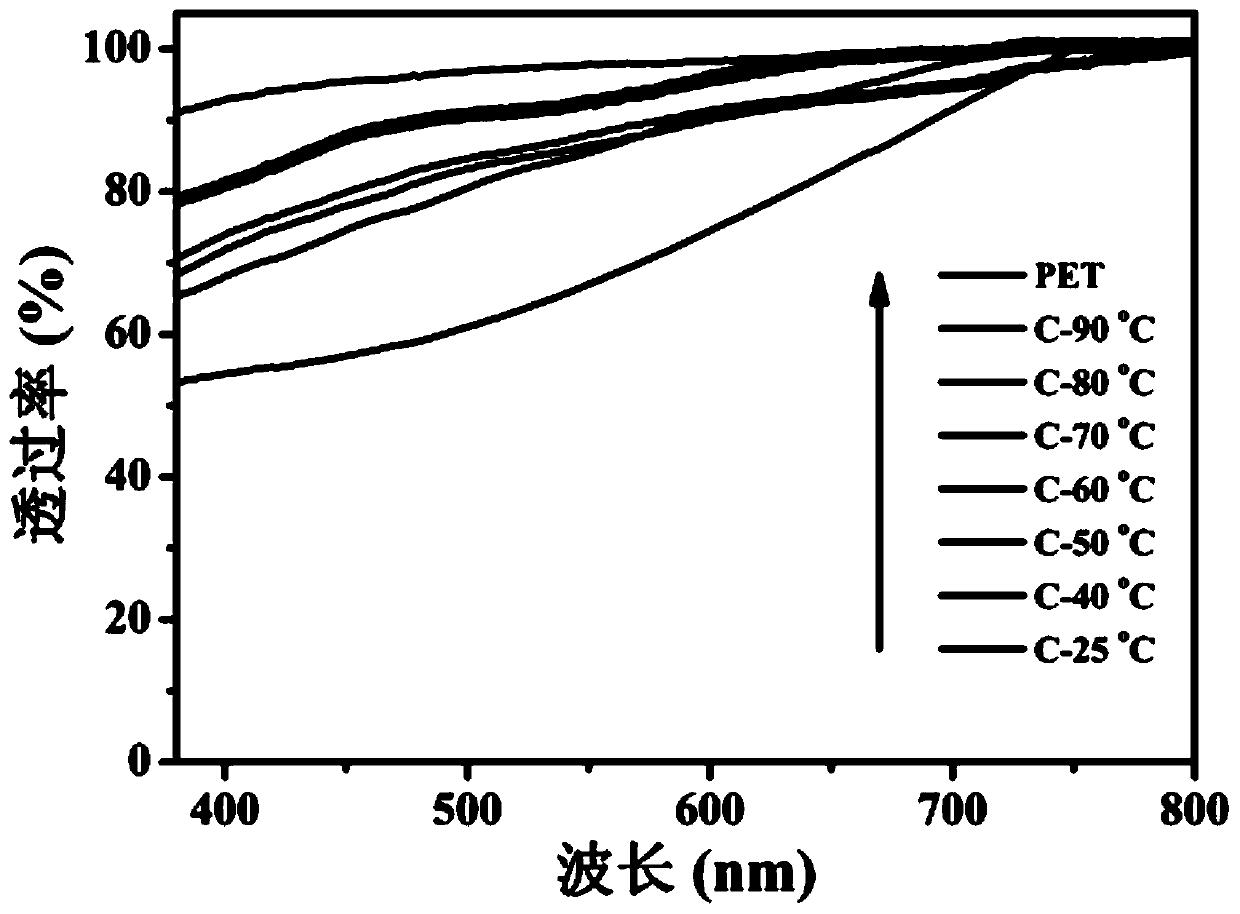

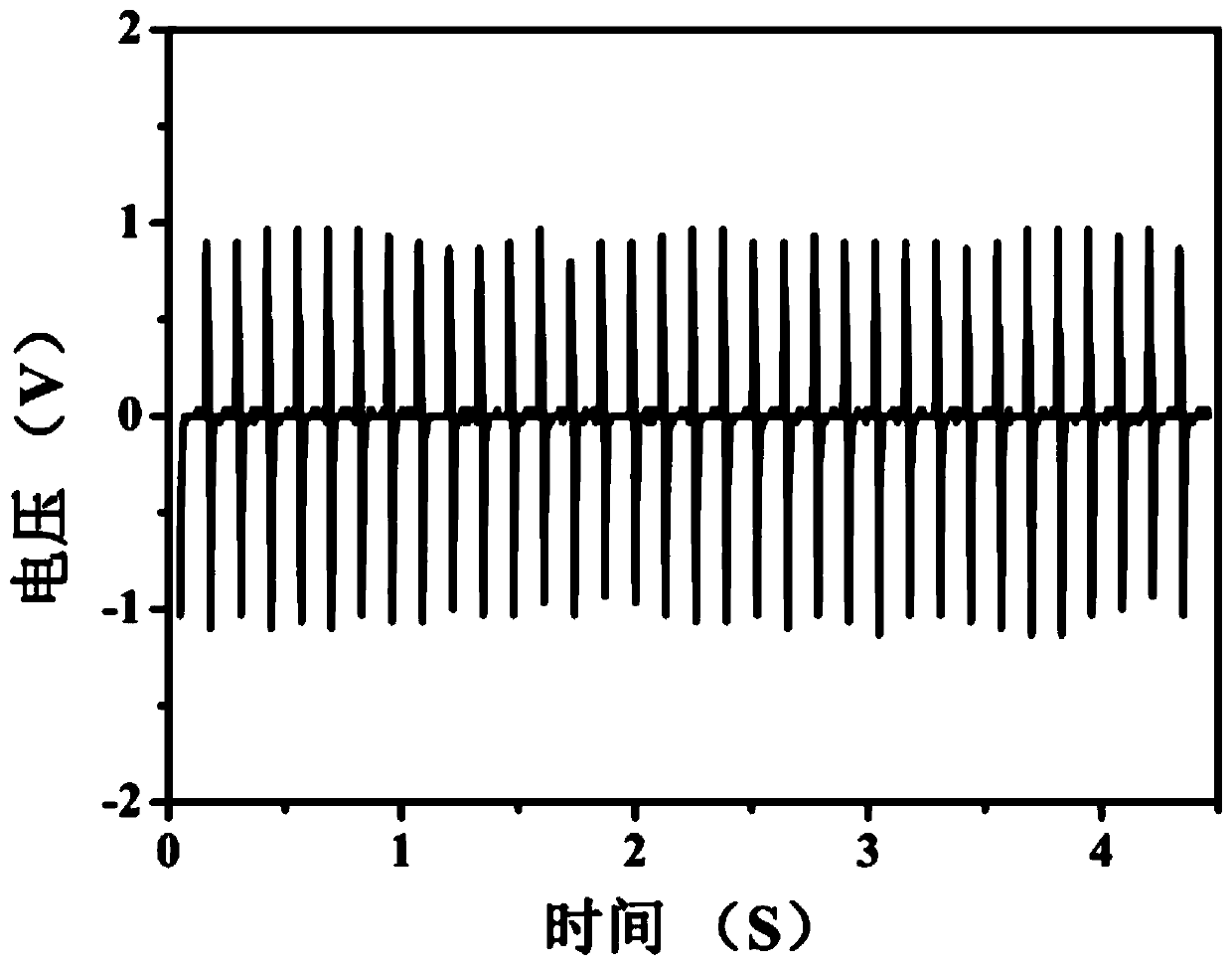

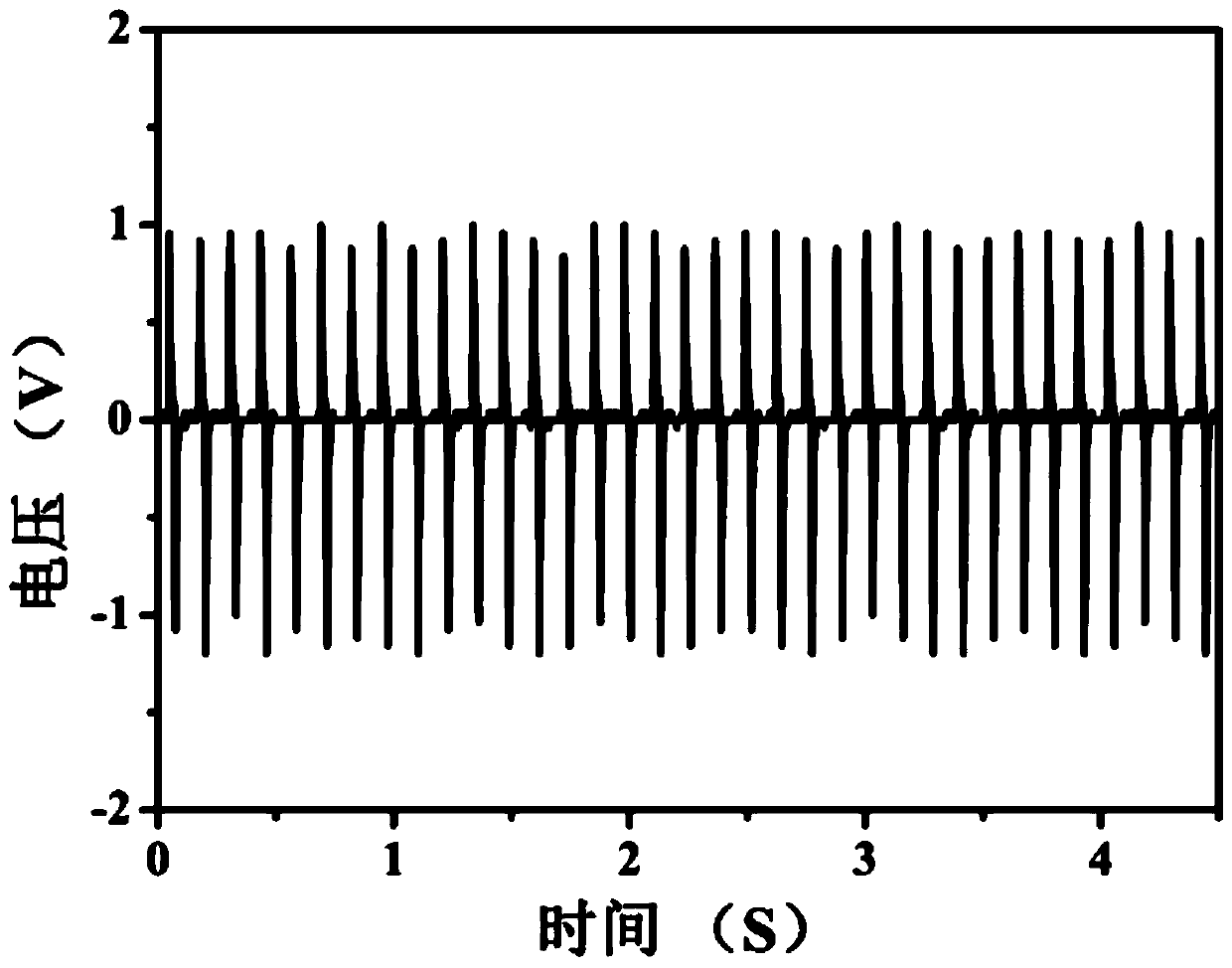

[0047] This embodiment relates to a method for rapidly preparing a polyvinylidene fluoride piezoelectric touch film with a high content of β-phase by using a knife coating method.

[0048] The piezoelectric touch film includes a transparent flexible substrate, a metal electrode, and a β-phase vinylidene fluoride piezoelectric film that are arranged in sequence. The piezoelectric film includes β-phase PVDF and dabcoHReO 4 , β-phase PVDF accounts for 80% of the mass of the piezoelectric film.

[0049] The specific steps of the preparation method of the piezoelectric touch film are as follows:

[0050] 1) Dissolve 0.552g PVDF powder in 10mL N,N-dimethylformamide / acetone (DMF / Ac) mixed solvent, stir mechanically, then add 0.048gdabcoHReO 4 , continue to stir under heating conditions to obtain dabcoHReO 4 -PVDF mixed solution.

[0051] 2) Set the substrate temperature to room temperature (25°C), set the scraping speed to 10mm / s, and the distance between the scraper and the subst...

Embodiment 2

[0053] The piezoelectric touch film was prepared according to the method of Example 1, except that in step 2), the temperature of the substrate was set to 40°C.

Embodiment 3

[0055] The piezoelectric touch film was prepared according to the method of Example 1, except that in step 2), the substrate temperature was set to 50°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com