Preparation method and application of piezoelectric-triboelectric coupling induction material

An induction material, triboelectric technology, applied in triboelectric generators, piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, etc., can solve the problem of low force/electricity conversion efficiency and low output amplitude and other problems, to achieve the effect of high output conversion performance, wide response range and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

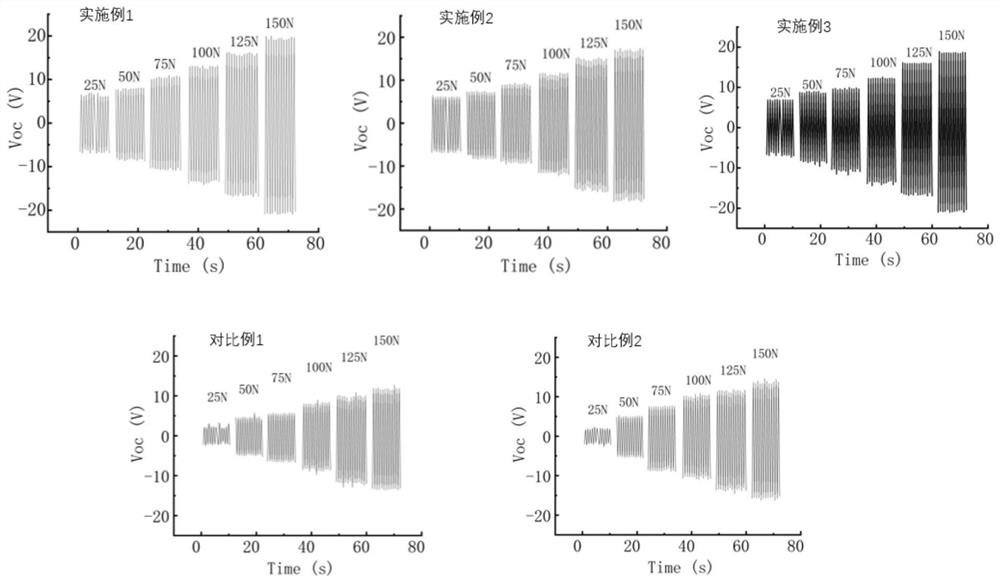

Embodiment 1

[0039] S1: Add 2 g of CTS to 87.5 g of acetic acid-water solution with a concentration of 1.5% and stir magnetically at room temperature until completely dissolved. Then, 10g HPC was slowly added to the above solution in 5 times every 30min, ultrasonic treatment was carried out at room temperature, the solution was allowed to stand at 10 °C for 6h, and 0.5g of CNT was taken out and placed at room temperature. After magnetic stirring for 3h, Let stand for 24h at room temperature, and then perform centrifugal degassing, the centrifugal degassing conditions are 10kpm, 30min, to obtain HPC / CTS / CNT solution;

[0040] S2: The HPC / CTS / CNT solution obtained in S1 was uniformly cast on a smooth and flat PTFE substrate. The surface of the solution after casting should be parallel to the substrate, and then slowly placed in an oven with a temperature of 55 °C for 8 hours. The water was lost until a film was formed by casting. After standing at room temperature for 2 h, the film was remov...

Embodiment 2

[0044] S1: Add 5 g of CTS to 85 g of acetic acid-water solution with a concentration of 0.5%, and stir magnetically for 30 min at room temperature until completely dissolved. Then, 9g HPC was slowly added to the above solution 9 times every 15min, and sonicated at room temperature until the concentration reached 9%. , after magnetic stirring for 2h, stand at room temperature for 30h, and then perform centrifugal degassing, the centrifugal degassing condition is 8kpm, 30min, to obtain HPC / CTS / CNT solution;

[0045] S2: The HPC / CTS / CNT solution obtained in S1 was uniformly cast on a smooth and flat PTFE substrate. The surface of the solution after casting should be parallel to the substrate, and then slowly placed in an oven at 50 °C for 12 hours. The water was lost until the film was cast, and then the film was taken off after standing at room temperature for 1 h and polarized at a voltage of 8 kV for 360 min to obtain a triboelectric positive electrode of piezoelectric-triboel...

Embodiment 3

[0049] The preparation method of piezoelectric-triboelectric coupling induction material includes the following steps:

[0050] S1: Add 3 g of CTS to 84.2 g of acetic acid-water solution with a concentration of 1.0%, and stir magnetically for 45 min at room temperature until completely dissolved. Then 12g HPC was slowly added to the above solution every 20min in 6 times, sonicated at room temperature until the concentration reached 12%, the solution was allowed to stand at 5°C for 4h, taken out and placed at room temperature and then added 0.8g of HPC CNT, after magnetic stirring for 6h, stand at room temperature for 27h, and then perform centrifugal degassing, centrifugal degassing conditions are 12kpm, 15min, to obtain HPC / CTS / CNT solution;

[0051] S2: The HPC / CTS / CNT solution obtained in S1 was uniformly cast on a smooth and flat PTFE substrate. The surface of the solution after casting should be parallel to the substrate, and then slowly placed in an oven at 55 °C for 6 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com