High-solid epoxy zinc phosphate primer paint and preparation method of high-solid epoxy zinc phosphate primer paint

An epoxy zinc phosphate, high-solid technology, applied in the field of coatings, can solve the problems of high organic volatile content, unfavorable environmental protection and health, low solid content, etc., and achieve the effect of reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

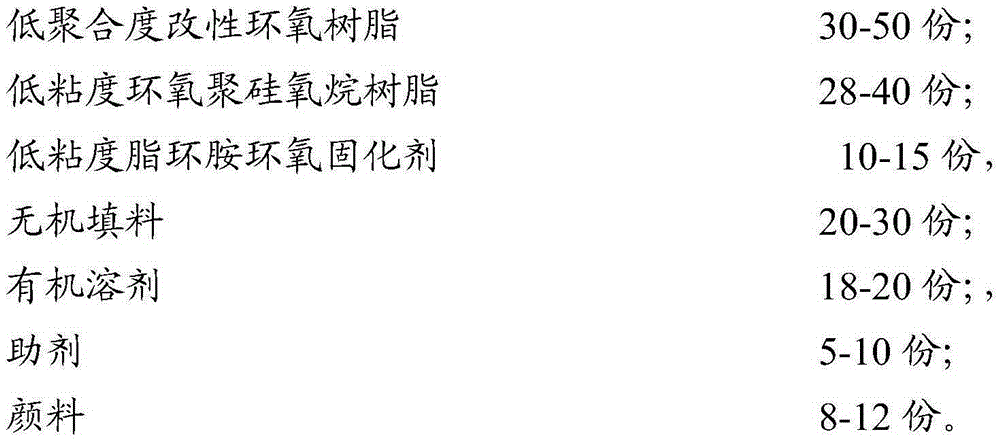

[0026] A kind of high-solid epoxy zinc phosphate primer paint, comprising by weight parts:

[0027]

[0028] The pigments include colored pigments and antirust pigments, and the weight ratio of the antirust pigments to the colored pigments is 1:1.

[0029] The antirust pigment is zinc phosphate antirust pigment.

[0030] The auxiliary agent includes a dispersant, a thickener, a defoamer and a leveling agent prepared in a ratio of 1:1.4:1:1 by weight.

[0031] Its preparation method comprises the following steps:

[0032] (1) Mix and disperse low-polymerization modified epoxy resin, low-viscosity epoxy polysiloxane resin, inorganic filler and organic solvent;

[0033] (2) Add additives and pigments to disperse;

[0034] (3) After adding low-viscosity cycloaliphatic epoxy curing agent, sanding, and then dispersing, the product can be obtained.

Embodiment 2

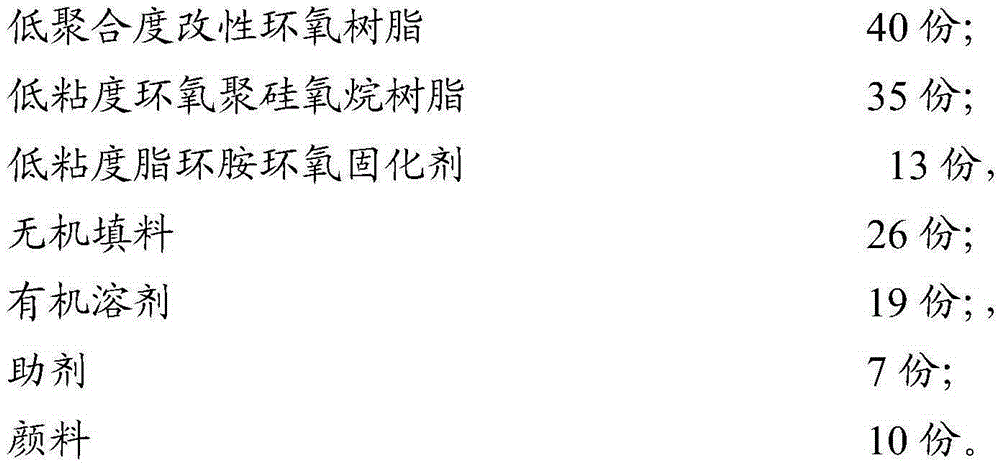

[0036] A kind of high-solid epoxy zinc phosphate primer paint, comprising by weight parts:

[0037]

[0038] The pigments include colored pigments and antirust pigments, and the weight ratio of the antirust pigments to the colored pigments is 1.5:1.

[0039] The antirust pigment is zinc phosphate antirust pigment.

[0040] The additives include dispersant, thickener, defoamer and leveling agent formulated according to the ratio of 1.6:1:1.9:1 by weight.

[0041] The preparation method is the same as in Example 1.

Embodiment 3

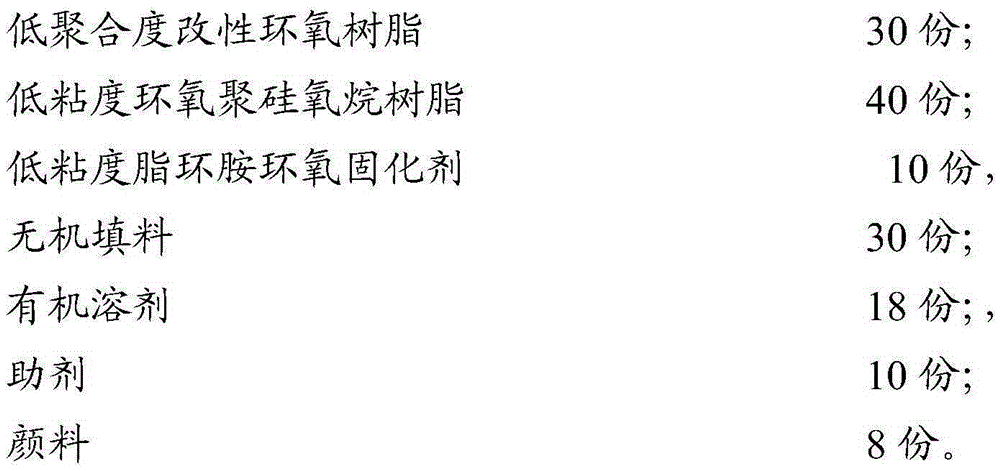

[0043] A kind of high-solid epoxy zinc phosphate primer paint, comprising by weight parts:

[0044]

[0045]

[0046] The pigments include colored pigments and antirust pigments, and the weight ratio of the antirust pigments to the colored pigments is 1.25:1.

[0047] The antirust pigment is zinc phosphate antirust pigment.

[0048] The auxiliary agent includes a dispersant, a thickener, a defoamer and a leveling agent prepared in a ratio of 1.3:1.14:1.5:1 by weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com