Sintering preparation method for zinc anode material

A zinc negative electrode and resin material technology, which is applied in the field of sintering preparation of zinc negative electrode materials, can solve problems such as difficult maintenance, zinc dendrites and zinc electrode deformation, dendrites, etc., and achieves broad application prospects, easy industrialization, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

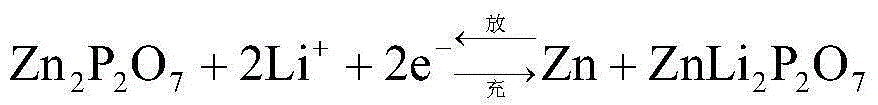

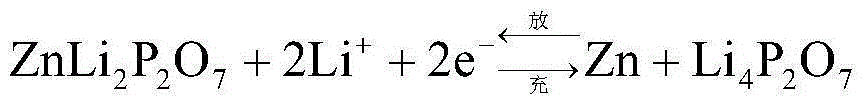

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Grind zinc carbonate to 200 mesh, mix ammonium dihydrogen pyrophosphate crushed to 200 mesh with zinc carbonate powder evenly, and the molar ratio of the total amount of zinc to the total amount of pyrophosphate is 2:1. The above mixture was placed in a ceramic boat and reacted in a high-temperature furnace under the protection of nitrogen. The linear flow rate of nitrogen in the reaction chamber was 5 cm / min, the heating rate was 1 °C / min, and the temperature was kept constant for 48 hours when the temperature was raised to 550 °C. After the constant temperature reaction is completed, the ceramic boat is immediately taken out from the high temperature furnace, left to cool at room temperature, and crushed to obtain the zinc negative electrode material. The zinc negative electrode material obtained according to the above preparation method is prepared into an electrode, and the specific capacity tested in a 1 mol / liter lithium sulfate solution is greater than 300mAh / g, a...

Embodiment 2

[0032] Mix zinc carbonate and zinc acetate with a molar ratio of 1:1 and grind them to 200 mesh, mix ammonium pyrophosphate and zinc carbonate and zinc acetate mixed powder evenly to 200 mesh, the molar ratio of the total amount of zinc to the total amount of pyrophosphate 2:1, add 400-mesh phenolic resin and mix by ball milling, wherein the amount of phenolic resin added is 20% of the total weight of raw materials. Press the above mixture into a thin sheet of about 1 mm under a pressure of 20 MPa, place it in a ceramic boat, and react in a high-temperature furnace under the protection of nitrogen. The linear flow rate of nitrogen in the reaction chamber is 5 cm / min, and the heating rate is 1 ° C / min, when the temperature was raised to 850°C, the temperature was kept constant for 4h. Immediately after the constant temperature reaction, the ceramic boat was taken out from the high-temperature furnace, cooled at room temperature under the protection of nitrogen, and crushed to...

Embodiment 3

[0034] Mix and crush zinc carbonate and zinc acetate with a molar ratio of 1:1 to 200 mesh, mix and crush ammonium pyrophosphate and ammonium tripolyphosphate with a molar ratio of 1:1 to 200 mesh, mix the above zinc source and phosphorus source powder Uniform, the electric ratio of the total amount of zinc to the total amount of anions is 1:1, add 400-mesh phenolic resin and mix by ball milling, wherein the amount of phenolic resin added is 10% of the total weight of raw materials. Press the above mixture into a thin sheet of about 1 mm under a pressure of 20 MPa, wet the above sheet evenly with ethanol, dry it in the shade, place it in a ceramic boat, and react in a high-temperature furnace under the protection of nitrogen. The linear flow rate of nitrogen in the reaction chamber The temperature is 5cm / min, the heating rate is 5℃ / min, and the temperature is kept constant for 6h when the temperature is raised to 700℃. After the constant temperature reaction, the ceramic boat ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com