Method for preparing zinc phosphate by using low-grade zinc oxide ores

A zinc oxide ore, low-grade technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., to achieve the effect of rich raw material sources, good economic benefits, and easy washing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

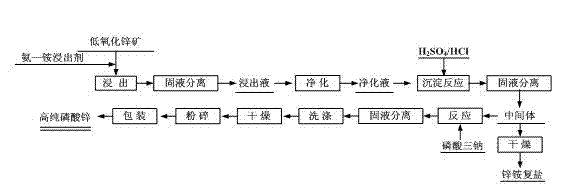

Method used

Image

Examples

Embodiment 1

[0027] In the ammonia leaching purification solution of low-grade zinc oxide ore, according to the Zn in the purification solution 2+ :H 2 SO 4 Add sulfuric acid (concentration 98%) at a molar mass ratio of 1:2.03-2.56, stir and react at room temperature for 35-40 minutes, let stand for 10-15 minutes and filter to obtain solid ammonium zinc sulfate, and dry at 65-75°C for 1-2 hours Standby; then prepare the dried ammonium zinc sulfate into an aqueous solution with a concentration of 40-60%, and then press ammonium zinc sulfate Zn 2+ : Na 3 PO 4 The molar ratio is 1:0.56~0.66, and a trisodium phosphate solution with a concentration of 25~50% is prepared, and the solution is slowly added to the zinc ammonium sulfate solution, and the reaction is kept at 75~85°C for 35~45 minutes while stirring, and then Filtrate, wash the filter cake with 150ml of water, and dry at 115-125°C for 2h-2.5h to obtain PO 4 3- Content≥45%, Zn 2+ High-purity zinc phosphate dihydrate products wit...

Embodiment 2

[0029] Measure 300ml of ammonia-ammonium sulfate leaching purification solution (the main chemical composition is shown in Table 1), add it to a 1L flat-bottomed beaker, press the purification solution Zn 2+ :H 2 SO 4 Add sulfuric acid (concentration 98%) at a molar mass ratio of 1:2.53, stir and react at room temperature for 40 minutes, and filter after standing for 10 minutes to obtain solid ammonium zinc sulfate; Aqueous solution, according to Zn 2+ : Na 3 PO 4 The molar ratio is 1:0.56, the concentration is 50% trisodium phosphate solution, and the solution is slowly added to the zinc ammonium sulfate solution, stirred and kept at 75°C for 30 minutes, after filtering and washing the filter cake with 150ml water, The white product of zinc phosphate tetrahydrate was obtained, and then dried at 110°C for 3 hours to obtain the product of zinc phosphate dihydrate, and the PO in the product was measured. 4 3- The content is 45.01%, Zn 2+The content is 45.09%. The product...

Embodiment 3

[0033] Measure 300ml of ammonia-ammonium sulfate leaching purification solution (the main chemical composition is shown in Table 1), add it to a 1L flat-bottomed beaker, press the purification solution Zn 2+ :H 2 SO 4 Add a sulfuric acid precipitant with a concentration of 98% at a molar mass ratio of 1:2.03, stir and react at room temperature for 50 minutes, let stand for 15 minutes and filter to obtain solid ammonium zinc sulfate, dry at 70°C for 2 hours for later use; then place in a 400mL flat-bottomed beaker Prepare the dried ammonium zinc sulfate into an aqueous solution with a concentration of 60%, according to Zn 2+ : Na 3 PO 4 The molar ratio is 1:0.62, and a trisodium phosphate solution with a concentration of 25% is prepared, and the solution is slowly added to the ammonium zinc sulfate solution, stirred and kept at 60°C for 50 minutes, and filtered, and the filter cake is washed with 150ml of water , the white product of zinc phosphate tetrahydrate was obtained...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com