Acid pickling process of carbon structural steel tube

A technology of carbon structure and steel pipe acid, which is applied in the field of pickling process, can solve the problems of affecting factory efficiency, the reduction of steel pipe yield, and the consumption of sulfuric acid, so as to reduce corrosion and hydrogen generation, reduce hydrogen embrittlement, and reduce exploitation speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The preferred embodiments of the present invention are described in detail below, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

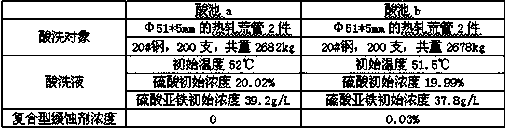

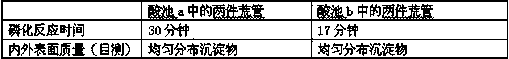

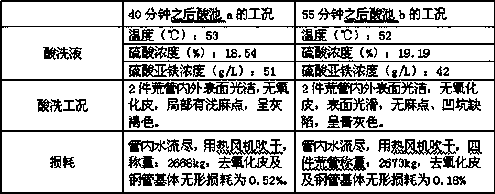

[0012] Embodiment: Carry out conventional pickling process in acid pond a, in acid pond b, add compound type corrosion inhibitor in common pickling solution, this compound type corrosion inhibitor is formulated by the composition of following mass percent: Benzene Ammonium bromide 70~80%, zinc phosphide 8~12% and zinc carbonate 8~12%. In this example, the composite corrosion inhibitor is specifically prepared from the following components by mass percentage: 80% benzalkonium bromide, 10% zinc phosphide and 10% zinc carbonate.

[0013] The corrosion inhibition mechanism of this composite corrosion inhibitor is as follows: after benzalkonium bromide is dissolved in water, an oxide film, that is, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com