No.4 main shaft oil and production method thereof

A production method and spindle oil technology, applied in the petroleum industry, lubricating compositions, etc., can solve problems affecting the precision of machine tool spindles, spindle oil film thickness, viscosity and unsatisfactory rust resistance, etc., and achieve low cost and thin oil film Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] A No. 4 spindle oil, the raw materials and weight percentages used are as follows:

[0014] 25# transformer oil 35-50%

[0015] Defatted paraffin oil 15 to 40%

[0016] Antioxidant 7-15%

[0017] Dodecenylsuccinic acid 4-14%

[0018] Zinc Phosphate 10 to 25%

[0019] Polyisobutylene 3 to 12%.

[0020] The production method of the No. 4 spindle oil is carried out according to the following steps: at normal temperature and pressure, add 25# transformer oil and degreased paraffin oil into the container, heat it to 80-90 ℃, stir to dissolve all of them, then add antioxidants, ten After the dienylsuccinic acid, polyisobutylene and zinc phosphate are all dissolved in each other after stirring, stop the stirring, lower the temperature below 40°C, sample and test, and enter the packaging process.

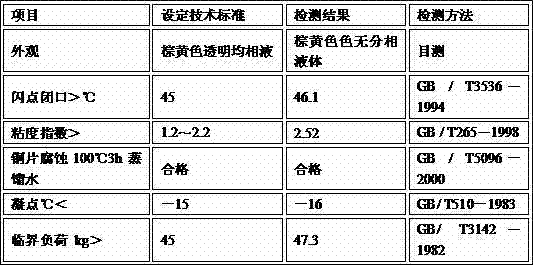

[0021] The indicators of the test items are as follows:

[0022]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com