Calcium zinc phosphate/bagasse composite anti-corrosion pigment and preparation method thereof

A zinc-calcium phosphate and anti-corrosion pigment technology, which is applied in the field of material chemistry, can solve the problems of small particle size of zinc-calcium phosphate powder, cumbersome preparation method of zinc-calcium phosphate, and restricted performance, so as to improve anti-corrosion performance, high efficiency and rapid Synthesis, excellent anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

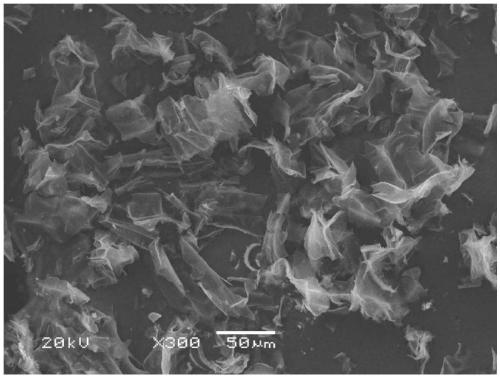

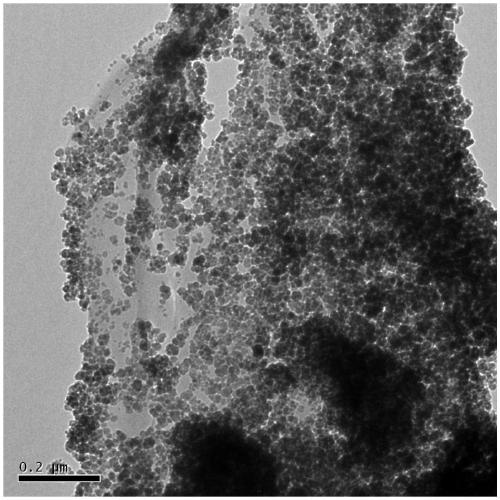

Image

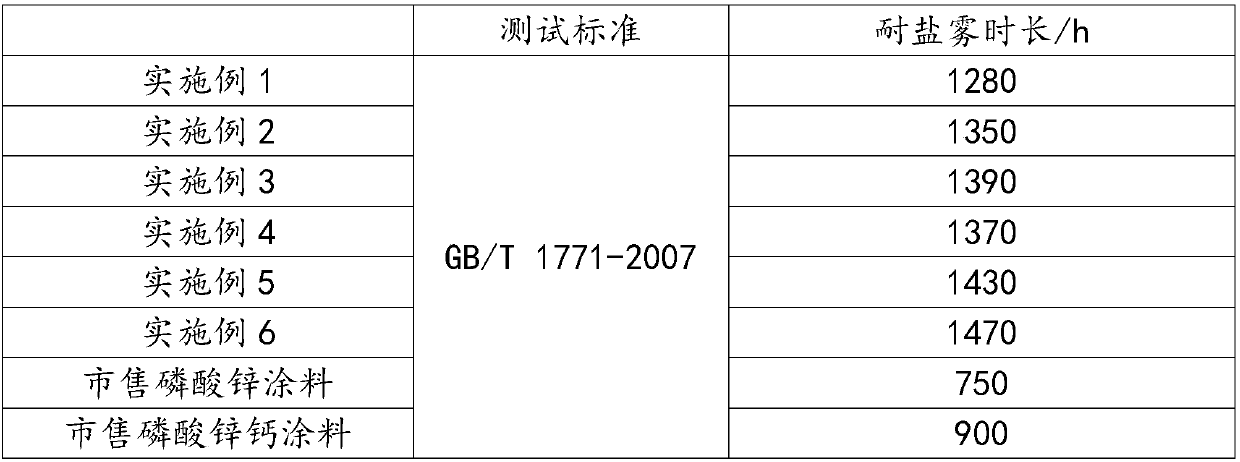

Examples

Embodiment 1

[0024] Take 20mL each of 0.04mmol / L zinc chloride and 0.02mmol / L calcium chloride solution, and 2g of pretreated bagasse, put them in a 100ml three-neck bottle and soak them for 3h, then put them into an ultrasonic instrument, and the ultrasonic power Set at 200w, under the condition of ultrasonic stirring, slowly add 0.01mol / L phosphoric acid solution dropwise, the time to complete the dropwise addition is 1h; obtain a solid product after filtration, wash the product with deionized water and ethanol, and then dry it to obtain Zinc calcium phosphate / bagasse composite anticorrosion pigment.

Embodiment 2

[0026] Take 20mL each of 0.04mmol / L zinc chloride and 0.04mmol / L calcium chloride solution, and 2g of pretreated bagasse, soak in a 100ml three-neck bottle for 3h, then put it into an ultrasonic instrument, and the ultrasonic power Set at 200w, under the condition of ultrasonic stirring, slowly add 0.01mol / L phosphoric acid solution dropwise, the time to complete the dropwise addition is 2h; obtain a solid product after filtration, wash the product with deionized water and ethanol, and then dry it to obtain Zinc calcium phosphate / bagasse composite anticorrosion pigment.

Embodiment 3

[0028] Take 20mL each of 0.04mmol / L zinc chloride and 0.02mmol / L calcium chloride solution, and 2g of pretreated bagasse, soak them in a 100ml three-neck bottle for 12h, then put them into an ultrasonic instrument, and the ultrasonic power Set at 300w, under the condition of ultrasonic stirring, slowly add 0.03mol / L phosphoric acid solution dropwise, the time to complete the dropwise addition is 5h; obtain a solid product after filtration, wash the product with deionized water and ethanol, and then dry it to obtain Zinc calcium phosphate / bagasse composite anticorrosion pigment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com