Method for preparing calcium phosphate cement/chitosan-gelatine composite porous holder

A technology of calcium phosphate bone cement and porous scaffold, applied in bone implants, medical science, prostheses, etc., can solve the problems of irregular hole shape, particle residue, poor connectivity between holes, etc., and achieve a good combination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

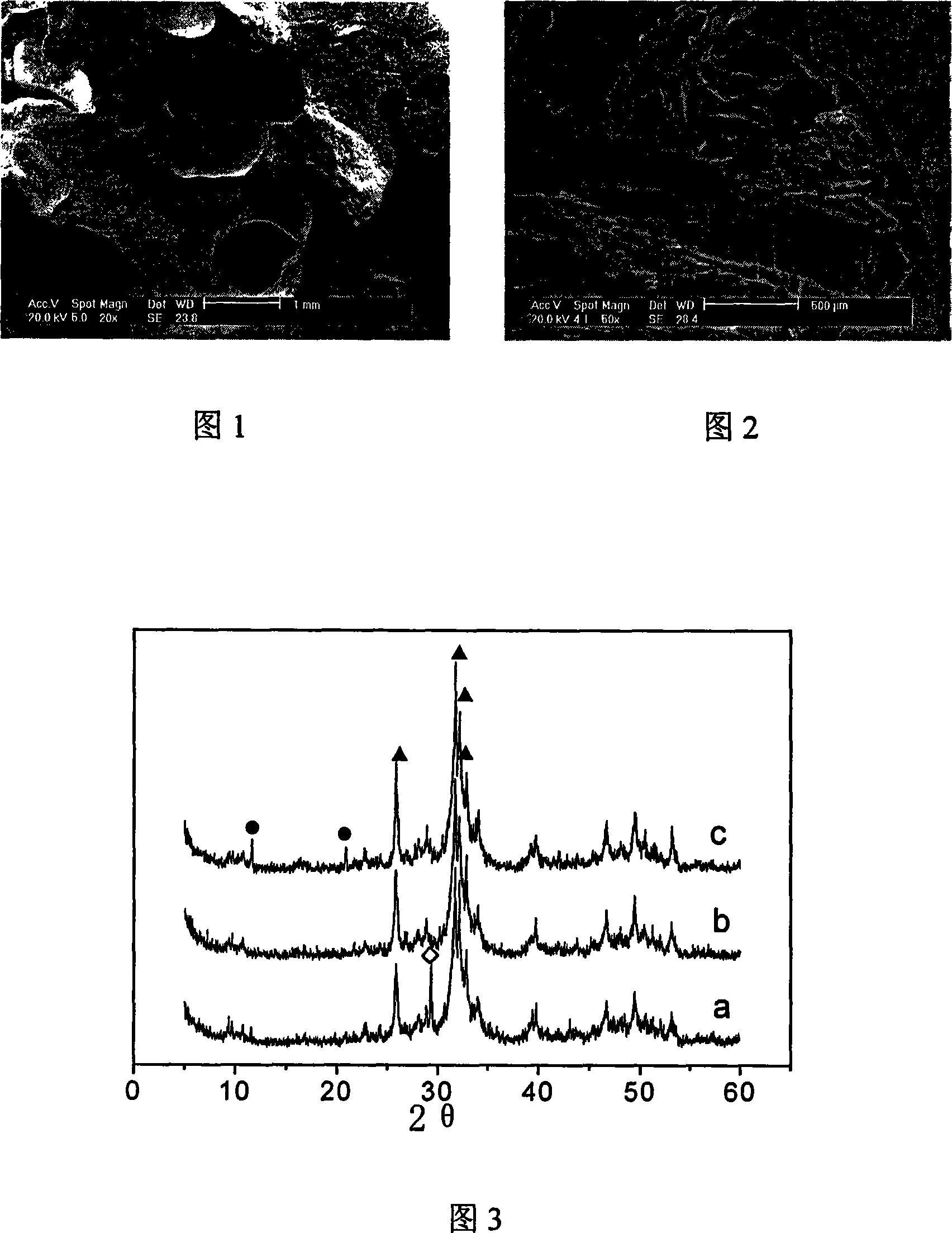

Embodiment 1

[0021] Calcium phosphate bone cement solid-phase powder was obtained by grinding 6.3 g of α-tricalcium phosphate with a particle size of 6.34 μm, 1.0 g of calcium dihydrogen phosphate monohydrate, 0.85 g of hydroxyapatite, and 1.85 g of calcium carbonate. The disodium hydrogen phosphate solution with a mass concentration of 0% is used as the solidification solution. Pour 1g of calcium phosphate bone cement solid phase powder into a clean crucible, take 0.9ml of solidified liquid water and add it to the calcium phosphate bone cement solid phase powder at room temperature, stir quickly with a medicine spoon, and then fill the paste into the mold Inside, squeeze out as much gas as possible. Put the mold containing the sample in a vacuum bottle and evacuate to 0.01MPa, then place the sealed vacuum bottle in a 60°C oven for foaming and curing for 2 hours, take out the mold, demould the sample, and place it at 37°C and 100% relative humidity After fully curing for 72 hours, the cal...

Embodiment 2

[0023] The experimental conditions and process of the present embodiment are the same as in Example 1, except that the mass concentration of the chitosan-gelatin solution adopted has been changed, and the chitosan-gelatin solution of 3% mass concentration is prepared, wherein the chitosan consumption is 0.27 g. The dosage of gelatin is 0.63g, and the dosage of glutaraldehyde solution containing 0.25% in mass concentration is 3mL. Then calcium phosphate bone cement porous scaffold is added in this chitosan-gelatin solution, the porosity of calcium phosphate bone cement / chitosan-gelatin composite porous scaffold obtained in the present embodiment is 66%, and compressive strength is 1.7MPa, The compressive modulus is 124MPa.

Embodiment 3

[0025] The test conditions and process of the present embodiment are the same as in Example 1, the prepared calcium phosphate bone cement porous support is not added to the chitosan-gelatin solution and poured in, the calcium phosphate bone cement support obtained in the present embodiment The porosity is 77%, the compressive strength is 0.33MPa, and the compressive modulus is 17MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com