Hyperbranched polyester-polycarboxylate water reducing agent and preparation method for same

A hyperbranched polyester and polycarboxylic acid-based technology, applied in the field of concrete admixtures, can solve the problems of high production cost, poor adaptability and poor adaptability of cement and polycarboxylic acid-based water-reducing agents, and achieves increased water-reducing, Improve dispersibility retention performance and increase the effect of steric hindrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

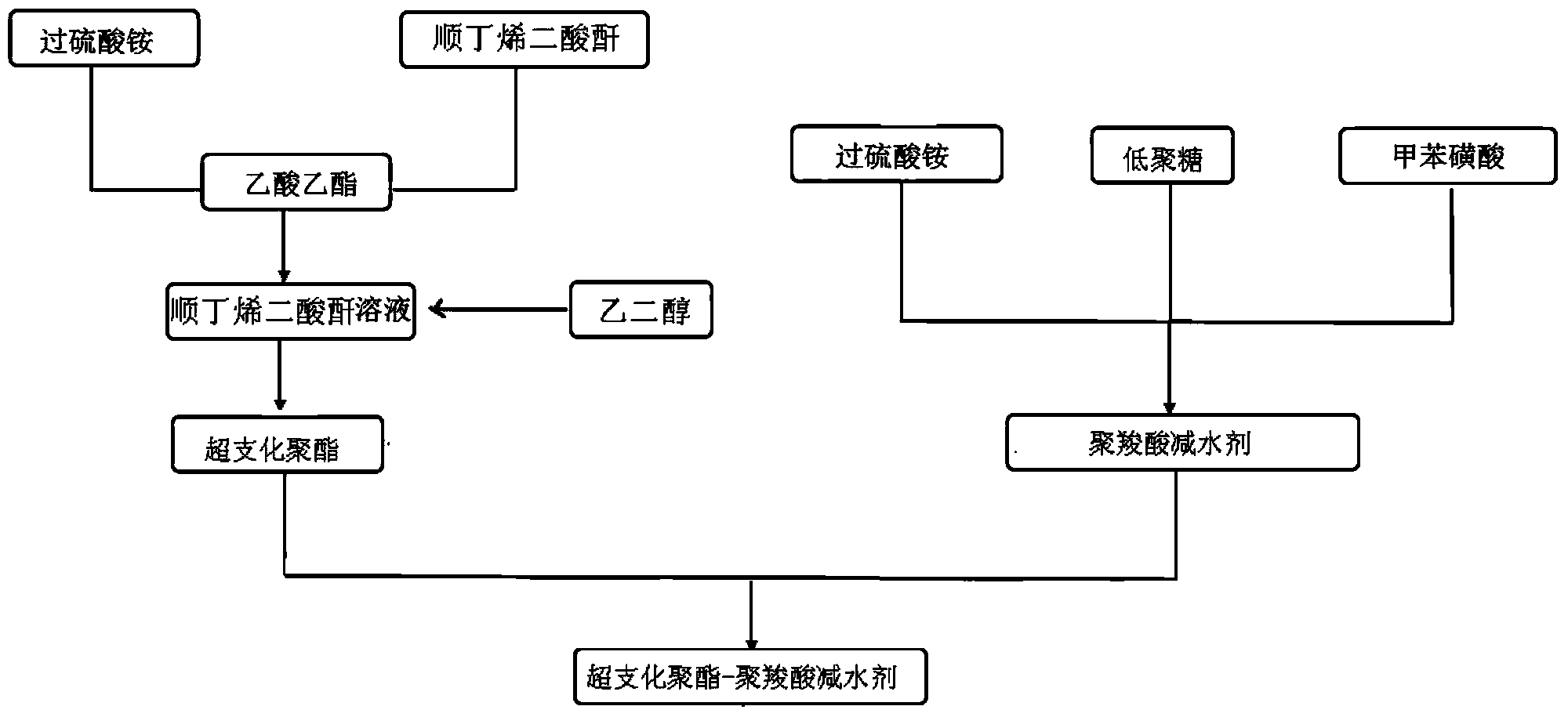

[0025] A kind of preparation method of hyperbranched polyester-polycarboxylate water reducer is realized through the following steps, as figure 1 Shown:

[0026] 1) Synthesis of hyperbranched polyester:

[0027] Add maleic anhydride and ammonium persulfate to ethyl acetate, the molar ratio of maleic anhydride to ethyl acetate is 2:1, and the ammonium persulfate is 0.25% of the molar number of maleic anhydride. Dissolve completely to obtain a maleic anhydride solution; then add ethylene glycol at a molar ratio of 0.2:1 to maleic anhydride, wherein, during the addition of ethylene glycol, the flow rate is 0.4ml / min, 30°C, The stirring speed is 40r / min, and then at 30°C and the stirring speed is 40r / min, react for 20h to obtain a hyperbranched polyester solution;

[0028] 2) Synthesis of hyperbranched polyester-polycarboxylate water reducer:

[0029] Toluenesulfonic acid, ammonium persulfate and oligosaccharides are added to the polycarboxylate water reducer with a mass fracti...

Embodiment 2

[0032] A kind of preparation method of hyperbranched polyester-polycarboxylate water reducer is realized by following steps, as figure 1 Shown:

[0033] 1) Synthesis of hyperbranched polyester:

[0034] Add maleic anhydride and ammonium persulfate to ethyl acetate, the molar ratio of maleic anhydride to ethyl acetate is 4:1, ammonium persulfate is 0.5% of the molar number of maleic anhydride, and wait Dissolve completely to obtain a maleic anhydride solution; then add ethylene glycol at a molar ratio of 1:1 to maleic anhydride, wherein, during the addition of ethylene glycol, the flow rate is 0.8ml / min, 35°C, The stirring speed is 60r / min, and then at 35°C and the stirring speed is 60r / min, react for 25h to obtain a hyperbranched polyester solution;

[0035] 2) Synthesis of hyperbranched polyester-polycarboxylate water reducer:

[0036]Add p-toluenesulfonic acid, ammonium persulfate and oligosaccharides to the polycarboxylate water reducer with a mass fraction of 40%, adjus...

Embodiment 3

[0039] A kind of preparation method of hyperbranched polyester-polycarboxylate water reducer is realized through the following steps, as figure 1 Shown:

[0040] 1) Synthesis of hyperbranched polyester:

[0041] Add maleic anhydride and ammonium persulfate to ethyl acetate, the molar ratio of maleic anhydride to ethyl acetate is 6:1, and the ammonium persulfate is 1% of the molar number of maleic anhydride. Dissolve completely to obtain a maleic anhydride solution; then add ethylene glycol at a molar ratio of 2.5:1 to maleic anhydride, wherein, during the addition of ethylene glycol, the flow rate is 1.0ml / min, 40°C, The stirring speed is 90r / min, and then at 40°C and the stirring speed is 90r / min, react for 30h to obtain a hyperbranched polyester solution;

[0042] 2) Synthesis of hyperbranched polyester-polycarboxylate water reducer:

[0043] Toluenesulfonic acid, ammonium persulfate and oligosaccharides are added to the polycarboxylate water reducer with a mass fraction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com