Concrete retarder

A technology of retarder and concrete, applied in the field of concrete retarder, can solve the problems of unsatisfactory concrete strength and air pollution, achieve good ion exchange function, improve adsorption performance, and increase the effect of adsorption contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

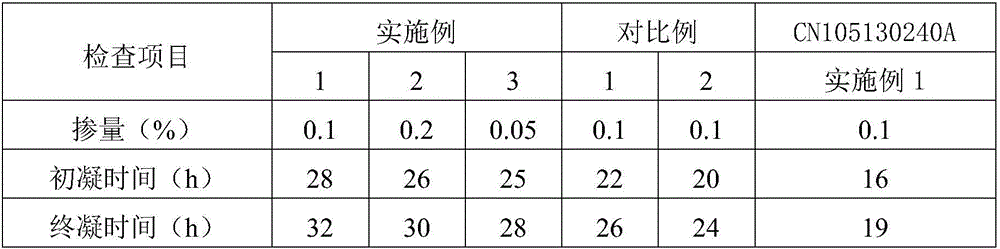

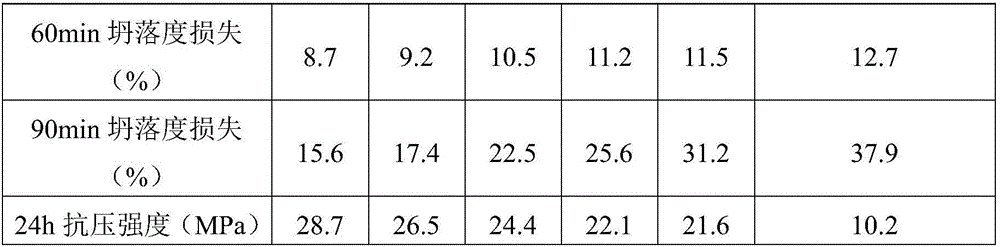

Examples

Embodiment 1

[0043] A concrete retarder, made of the following components in proportion by weight: 3 parts of sodium borate, 5 parts of potassium dihydrogen phosphate, 6 parts of calcium sulfate, 7 parts of hydroxyethylidene diphosphonic acid, ethylenediamine tetra 4 parts of disodium acetate, 3 parts of sorbitol, 27 parts of bentonite, 12 parts of vermiculite powder, 5 parts of water reducing agent, 2 parts of dispersant, 0.6 part of surfactant.

Embodiment 2

[0045] A concrete retarder, made of the following components in proportion by weight: 2 parts of sodium borate, 3 parts of potassium dihydrogen phosphate, 4 parts of calcium sulfate, 6 parts of hydroxyethylidene diphosphonic acid, ethylenediamine tetra 3 parts of disodium acetate, 1 part of sorbitol, 25 parts of bentonite, 10 parts of vermiculite powder, 4 parts of water reducer, 1 part of dispersant, 0.4 part of surfactant.

Embodiment 3

[0047] A concrete retarder, made of the following components in proportion by weight: 4 parts of sodium borate, 7 parts of potassium dihydrogen phosphate, 8 parts of calcium sulfate, 8 parts of hydroxyethylidene diphosphonic acid, ethylenediamine tetra 5 parts of disodium acetate, 4 parts of sorbitol, 30 parts of bentonite, 15 parts of vermiculite powder, 6 parts of water reducer, 3 parts of dispersant, and 0.8 part of surfactant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com