Nylon rapid-dyeing color-homogenizing agent

A nylon and colorant technology, applied in the field of textile dyeing and finishing, can solve the problems of long dyeing process time, color pattern, accelerated instantaneous dyeing, etc., and achieve excellent acid release effect, prevent dyeing, and improve dyeing rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] The preparation method of the described a kind of nylon fast dyeing and leveling agent is realized according to the following steps: 1) fully stir and mix 40-50% ethylene glycol dicarboxylate and 5-10% ethylene glycol; obtain the mixture ; 2) Add 20-30% of stearylamine polyoxyethylene ether and 15-20% of Tween-80 into the mixture in turn, and stir and mix together to obtain nylon quick dyeing and leveling agent.

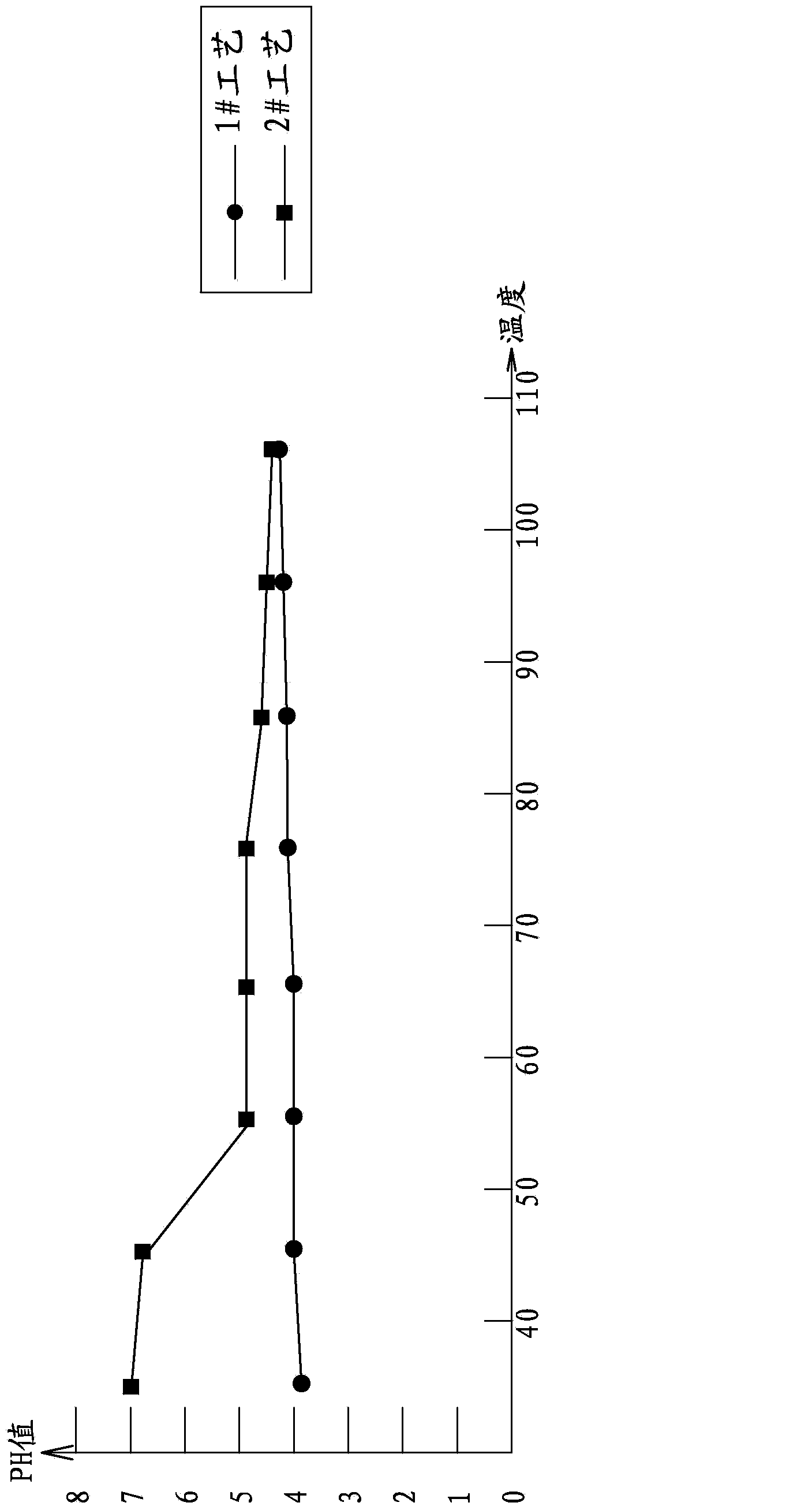

[0018] A kind of quick dyeing and leveling agent for nylon of the present invention, at first, though ethylene glycol dicarboxylate is weakly acidic at normal temperature, but the pH value is close to 7, can effectively prevent weakly acidic dyes from being dyed at low temperature, and has It is conducive to the slow dyeing of weak acid dyes, so the dyeing of weak acid dyes can be controlled by 2-3°C / min. rapid temperature rise during the dyeing process, which greatly shortens the entire dyeing process time; With the gradual increase of dyeing temperature, eth...

Embodiment 1

[0020] A kind of nylon fast dyeing and leveling agent of the present invention is specifically prepared from the following parts by weight: 50 parts by weight of ethylene glycol dicarboxylate, 5 parts by weight of ethylene glycol, 30 parts by weight of octadecylamine polyoxygen vinyl ether, and 15 parts by weight of Tween-80.

[0021] The preparation method of described nylon fast dyeing leveling agent, realizes as follows:

[0022] 1) fully stirring and mixing the ethylene glycol diformate of 50 parts by weight and the ethylene glycol of 5 parts by weight;

[0023] get the mixture;

[0024] 2) Add 30 parts by weight of octadecylamine polyoxyethylene ether and 15 parts by weight of Tween-80 to the mixture respectively, and mix and compound with the mixture to obtain the instant nylon dyeing and leveling agent of the present invention.

Embodiment 2

[0026] A nylon fast dyeing and leveling agent of the present invention is specifically prepared from the following parts by weight: 40 parts by weight of ethylene glycol dicarboxylate, 10 parts by weight of ethylene glycol, 30 parts by weight of octadecylamine polyoxygen vinyl ether, and 20 parts by weight of Tween-80.

[0027] The preparation method of described nylon fast dyeing leveling agent, realizes as follows:

[0028] 1) fully stirring and mixing the ethylene glycol diformate of 40 parts by weight and the ethylene glycol of 10 parts by weight;

[0029] get the mixture;

[0030] 2) Add 30 parts by weight of stearylamine polyoxyethylene ether and 20 parts by weight of Tween-80 to the mixture respectively, and mix and compound with the mixture to obtain the instant nylon dyeing and leveling agent of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com