Alkali slag concrete composite activator and preparation method of concrete mixture

A compound excitation and concrete technology, which is applied in the field of compound excitation agent and preparation of alkali slag concrete mixture, can solve the problems of complex production process and increased cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

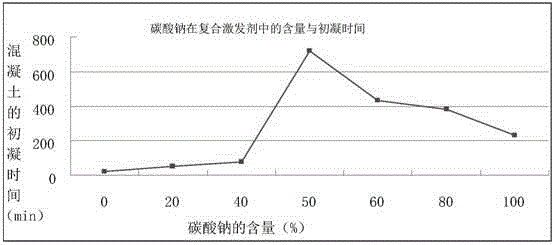

[0030]Embodiment 1, a kind of composite activator applied in alkali slag concrete, described composite activator is formed by mixing sodium carbonate and solid sodium hydroxide, wherein, the equivalent ratio of sodium carbonate and sodium hydroxide is 80 parts: 20 parts; said solid sodium hydroxide refers to the solid sodium hydroxide that exists in solid form in the preparation of alkali slag concrete mixture, directly mixes with powder materials and does not contact with water before sodium carbonate; Described sodium carbonate is sodium carbonate containing crystal water.

[0031] The preparation method of the above-mentioned composite activator applied in alkali slag concrete comprises the following steps,

[0032] The first step is to prepare the raw materials. The raw materials are an appropriate amount of aggregate and silicon-aluminum oxide as the main chemical composition, which has pozzolanic activity and has a specific surface area of 200 square meters per kilogra...

Embodiment 2

[0037] Embodiment 2 A composite activator applied in alkali slag concrete, the composite activator is formed by mixing sodium carbonate and solid sodium hydroxide, wherein the equivalent ratio of sodium carbonate and sodium hydroxide is 50 parts: 50 part; said solid sodium hydroxide refers to the solid sodium hydroxide that exists in solid form in the preparation of alkali slag concrete mixture, is directly mixed with powder materials and is not in contact with water before sodium carbonate; Sodium carbonate is sodium carbonate containing crystal water.

[0038] The preparation method of the above-mentioned composite activator applied in alkali slag concrete comprises the following steps,

[0039] The first step is to prepare the raw material, which is an appropriate amount of aggregate, which is obtained through high-temperature treatment or high-temperature processing stage, with silicon-aluminum oxide as the main chemical composition and pozzolanic activity, with a specific...

Embodiment 3

[0044] Embodiment 3, a kind of composite activator applied in alkali slag concrete, described composite activator is formed by mixing sodium carbonate and solid sodium hydroxide, wherein, the equivalent ratio of sodium carbonate and sodium hydroxide is 60 parts: 40 parts; said solid sodium hydroxide refers to the solid sodium hydroxide that exists in solid form in the preparation of alkali slag concrete mixture, is directly mixed with powder materials and is not in contact with water before sodium carbonate; Described sodium carbonate is sodium carbonate containing crystal water.

[0045] The preparation method of the above-mentioned composite activator applied in alkali slag concrete comprises the following steps,

[0046] The first step is to prepare the raw material, which is an appropriate amount of aggregate, which is obtained through high-temperature treatment or high-temperature processing stage, with silicon-aluminum oxide as the main chemical composition and pozzolani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com