Integrated catalytic membrane ozone gas distributor as well as preparation method and application thereof

A technology of gas distributor and catalytic membrane, which is applied in chemical instruments and methods, oxidized water/sewage treatment, water pollutants, etc., can solve the problems of destroying organic pollutants, low ozone utilization rate, low solubility, etc., and achieve recovery Difficulty, reduce the volume of equipment, improve the effect of mass transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

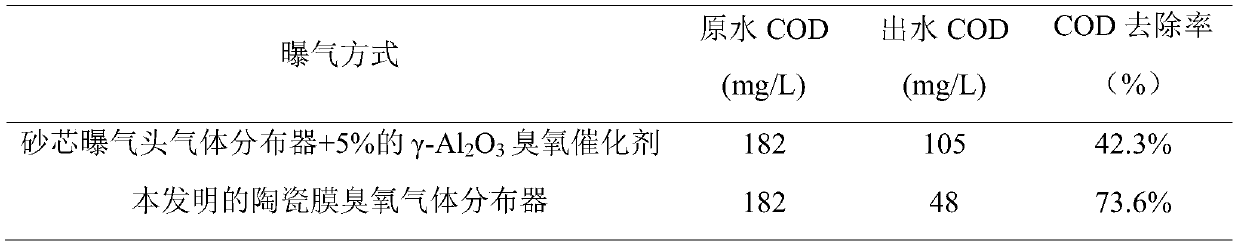

Embodiment 1

[0039] The preparation method of the catalytic membrane ozone gas distributor of the present embodiment is as follows:

[0040] Step 1: Al(OH) 3 The powder is calcined and calcined at 450°C for 6 hours to convert all of it into γ-Al 2 o 3 ;

[0041] Step 2: Pre-fired γ-Al 2 o 3 The powder is ground into uniform powder particles of 5000-6000 mesh for use;

[0042] Step 3: Wash the powder particles obtained in Step 2 with dilute sulfuric acid and dilute liquid alkali respectively, and finally wash with deionized water until the pH of the effluent is neutral, and dry at 100°C;

[0043] Step 4: Disperse the granular material obtained in step 3 in a solution containing polyvinyl alcohol as a binder, shake evenly to form a smear liquid, and then apply the smear liquid to the outer surface of the ceramic membrane main body by spraying to form a coating at 100°C drying;

[0044] Step 5: The catalytic ceramic membrane coated with the catalytic material in step 4 is fired twice a...

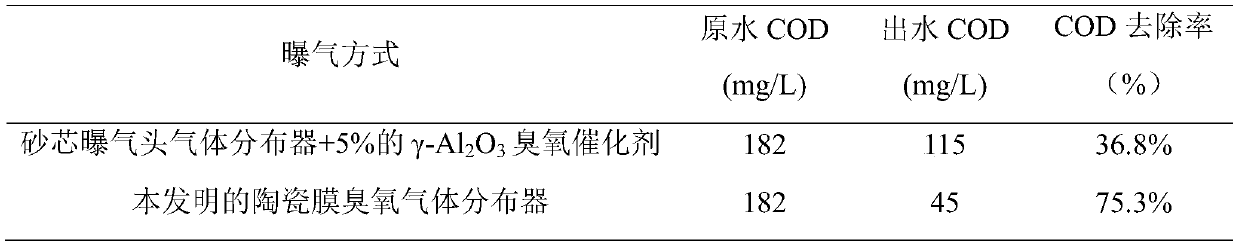

Embodiment 2

[0049] The preparation method of the catalytic membrane ozone gas distributor of the present embodiment is as follows:

[0050] Step 1: Al(OH) 3 The powder is roasted at 550°C for 5 hours to transform it into γ-Al 2 o 3 ;

[0051] Step 2: Pre-fired γ-Al 2 o 3 The powder is ground into uniform powder particles of 7000-8000 mesh for standby;

[0052] Step 3: Wash the powder particles obtained in Step 2 with dilute sulfuric acid and dilute liquid alkali respectively, and finally wash with deionized water until the pH of the effluent is neutral, and dry at 100°C;

[0053] Step 4: Disperse the granular material obtained in step 3 in a solution containing the binder carboxymethyl cellulose, shake it evenly to form a smear liquid, and then apply the smear liquid on the outer surface of the ceramic membrane main body by dipping and pulling to form a coating layer, drying at 100°C;

[0054] Step 5: The catalytic ceramic membrane coated with the catalytic material in step 4 is fi...

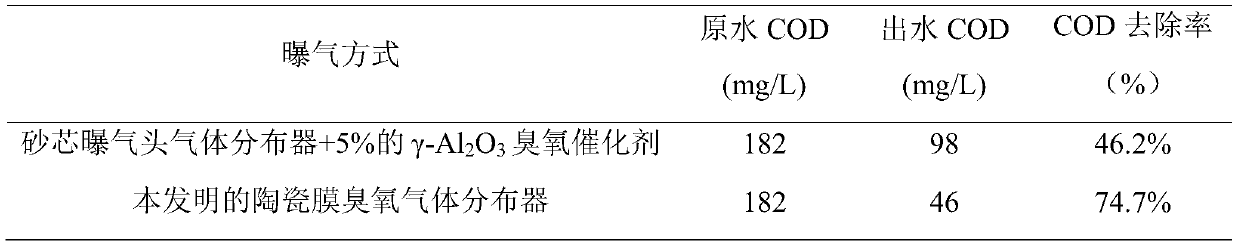

Embodiment 3

[0059] The ceramic membrane with ozone catalytic active material of the present embodiment is prepared by the following steps:

[0060] Step 1: Al(OH) 3 The powder is calcined at 650°C for 4 hours to convert all of it into γ-Al 2 o 3 ;

[0061] Step 2: Pre-fired γ-Al 2 o 3 The powder is ground into 9000-10000 mesh uniform powder particles for later use;

[0062] Step 3: Wash the powder particles obtained in Step 2 with dilute sulfuric acid and dilute liquid alkali respectively, and finally wash with deionized water until the pH of the effluent is neutral, and dry at 100°C;

[0063] Step 4: Disperse the granular material obtained in Step 3 in a solution containing a binder and polyvinyl butyral, shake it evenly to form a smear liquid, and then apply the smear liquid to the outer surface of the ceramic membrane body by spin coating to form Coating, drying at 100°C;

[0064] Step 5: The catalytic ceramic membrane coated with the catalytic material in step 4 is fired twice ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com