Polyphosphonic acid type water reducing agents and synthesis method thereof

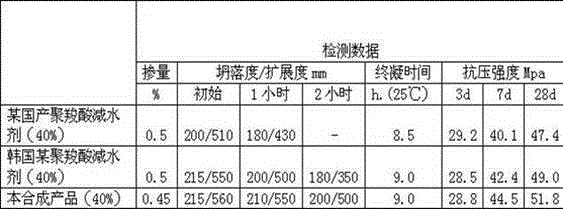

A synthesis method and water reducing agent technology are applied in the field of polyphosphonic acid water reducing agent and its synthesis, which can solve the problems of poor workability, high sensitivity, poor compatibility of different materials, etc., and achieve good water reducing effect. , Good slump retention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The raw material composition of polyphosphonic acid water reducer:

[0023] a. Methallyl polyoxyethylene ether

[0024] b. Acrylic

[0025] c. Vinylphosphonic acid

[0026] d. Ammonium persulfate

[0027] e. Thioglycolic acid

[0028] f. Trisodium phosphate;

[0029] Among them, the molar ratio of raw materials a, b, c, f: 1:3:0.2:2; raw material d is 0.2% of the total weight of the material; raw material e is 0.1% of the total weight of the material.

[0030] Its synthesis method is:

[0031] 1) Add b, c, and f together into water, mix and stir evenly to form a solution with a total content of 50%, then add e and stir evenly as dripping material A;

[0032] 2) Dissolve d in water to make a 10% solution as dripping material B;

[0033] 3) Add a into the reaction kettle filled with water, stir until it is completely dissolved, and make a 50% solution; raise the temperature of the reaction kettle to 60°C and start adding material A dropwise evenly, and finish addin...

Embodiment 2

[0036] The raw material composition of polyphosphonic acid water reducer:

[0037] a. Methallyl polyoxyethylene ether

[0038] b. Methacrylic acid

[0039] c. Vinylphosphonic acid

[0040] d. Ammonium persulfate

[0041] e. Mercaptopropionic acid

[0042] f. Trisodium phosphate;

[0043] Among them, the molar ratio of raw materials a, b, c, f is 1:4:1:3; raw material d is 0.5% of the total weight of the material; raw material e is 0.3% of the total weight of the material.

[0044] Its synthetic method is as embodiment 1.

Embodiment 3

[0046] The raw material composition of polyphosphonic acid water reducer:

[0047] a. Methallyl polyoxyethylene ether

[0048] b. Acrylic

[0049] c. Vinylphosphonic acid

[0050] d. Ammonium persulfate

[0051] e. Thioglycolic acid

[0052] f. Trisodium phosphate;

[0053] Among them, the molar ratio of raw materials a, b, c, f is 1:3.5:0.5:3; raw material d is 0.25% of the total weight of the material; raw material e is 0.18% of the total weight of the material.

[0054] Its synthetic method is as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com