Cement-based capillary crystalline waterproof material based on nanosilicon-based material and preparation method and application thereof

A technology of penetrating crystallization and waterproof materials, which is applied in the field of building waterproof materials, and can solve problems such as difficult to quickly repair concrete cracks and pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

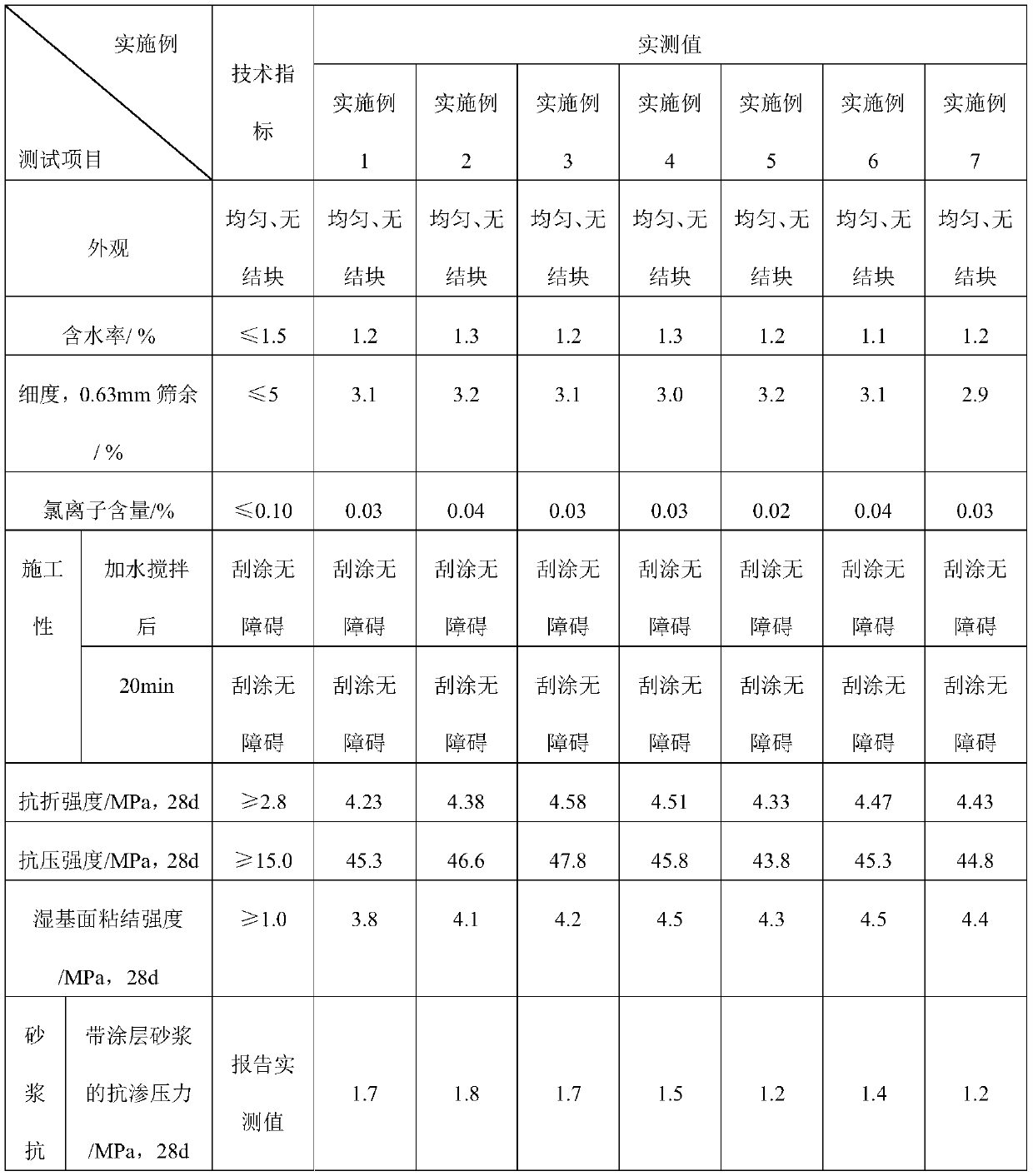

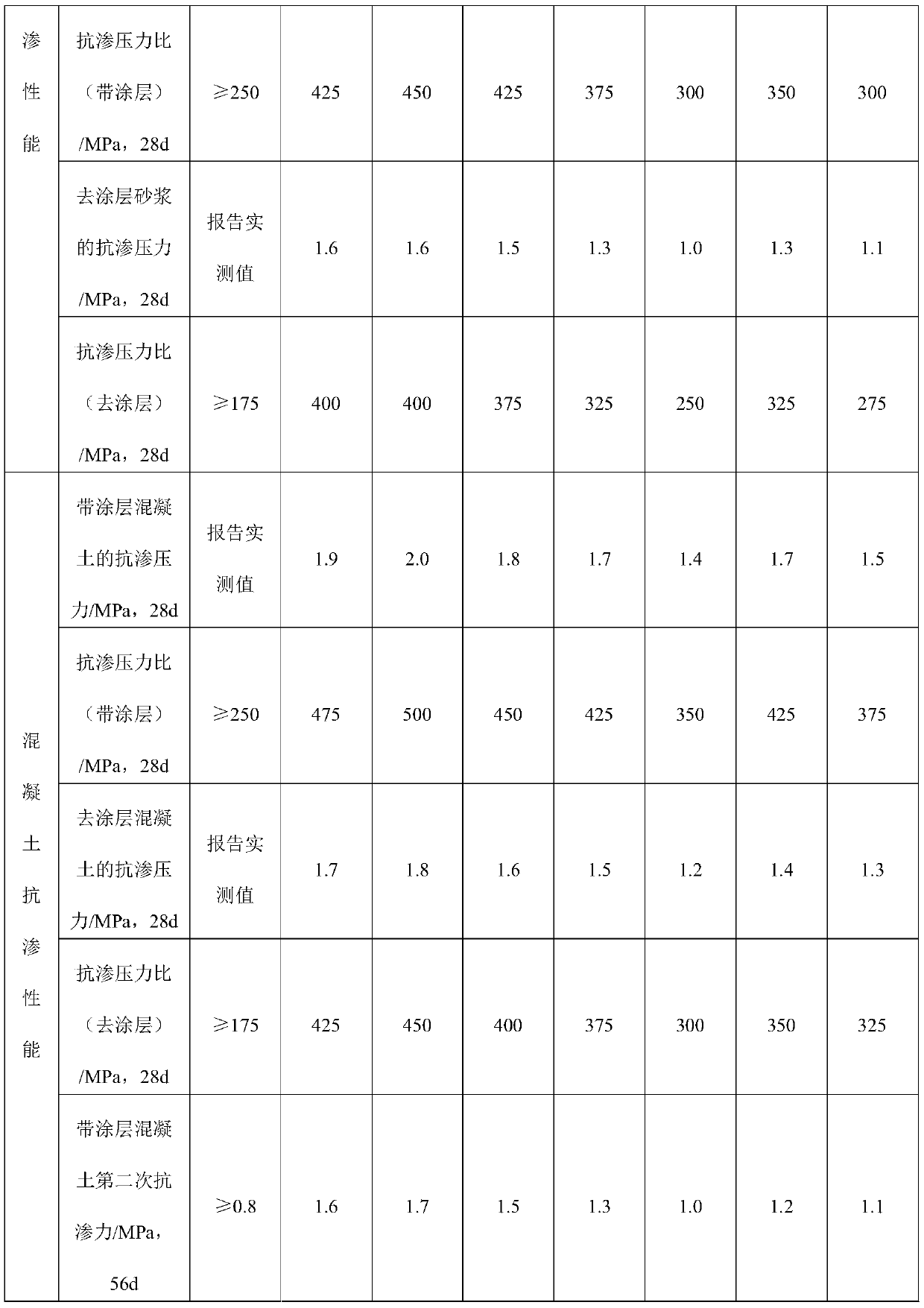

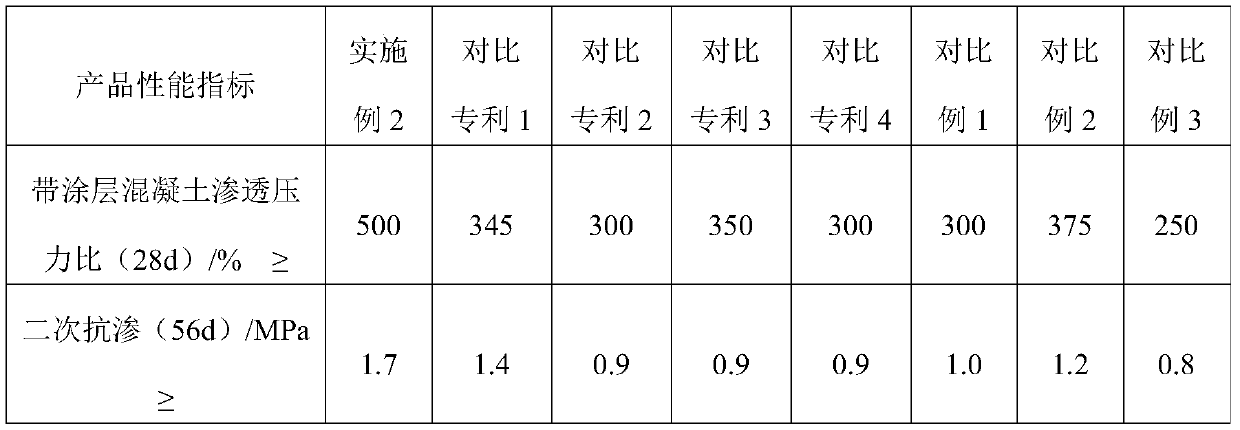

Examples

Embodiment 1

[0027] A cement-based permeable crystalline waterproof material is composed of the following raw materials in proportion by weight:

[0028] Portland cement 45 parts;

[0029] 31.4 parts of quartz sand;

[0030] 4 parts citric acid;

[0031] 12 parts of sodium carbonate;

[0032] 3 parts instant sodium silicate;

[0033] 0.4 parts of nano silicon dioxide;

[0034] 0.5 part of surfactant;

[0035] 0.5 parts of tartaric acid;

[0036] 1 part of calcium ion compensator;

[0037] 2 parts of polycarboxylate superplasticizer;

[0038] 0.2 parts of cellulose ether;

[0039] Wherein, the quartz sand is obtained by compounding 40-70 mesh, 70-100 mesh and 100-140 mesh, and the compounding weight ratio is specifically 1:2:1; the surfactant is dodecyl ethoxy sulfo Betaine; hydroxyethyl methyl cellulose ether with a viscosity of cellulose ether of 200-1500mPa·S.

Embodiment 2

[0041] A cement-based permeable crystalline waterproof material is composed of the following raw materials in proportion by weight:

[0042] Portland cement 55 parts;

[0043] 27 parts of quartz sand;

[0044] 3 parts citric acid;

[0045] 7 parts of sodium carbonate;

[0046] 1 part instant sodium silicate;

[0047] 0.4 parts of nano silicon dioxide;

[0048] 1.1 parts of surfactant;

[0049] 1.5 parts of tartaric acid;

[0050] 1 part of calcium ion compensator;

[0051] 2 parts of polycarboxylate superplasticizer;

[0052] 1 part of cellulose ether;

[0053] Wherein, the quartz sand is obtained by compounding 40-70 mesh, 70-100 mesh and 100-140 mesh, and the compounding weight ratio is specifically 1:2:1; the surfactant is dodecyl sulfopropyl betaine ; The viscosity of cellulose ether is hydroxyethyl methyl cellulose ether of 200-1500mPa·S.

Embodiment 3

[0055] A cement-based permeable crystalline waterproof material is composed of the following raw materials in proportion by weight:

[0056] 60 parts of Portland cement;

[0057] 18.5 parts of quartz sand;

[0058] 4 parts citric acid;

[0059] 10 parts of sodium carbonate;

[0060] 3 parts instant sodium silicate;

[0061] 0.1 part of nano silicon dioxide;

[0062] 0.5 part of surfactant;

[0063] 0.5 parts of tartaric acid;

[0064] 2 parts of calcium ion compensator;

[0065] 1 part of polycarboxylate superplasticizer;

[0066] 0.4 part of cellulose ether;

[0067] Wherein, the quartz sand is obtained by compounding 40-70 mesh, 70-100 mesh and 100-140 mesh, and the compounding weight ratio is specifically 1:2:1; the surfactant is dodecyl ethoxy sulfo Betaine or dodecyl sulfopropyl betaine; hydroxyethyl methyl cellulose ether with a viscosity of cellulose ether of 200-1500mPa·S.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com