Polycarboxylate type water reducing agent for concrete and preparation method thereof

A technology of polycarboxylate and concrete, applied in the field of concrete admixture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

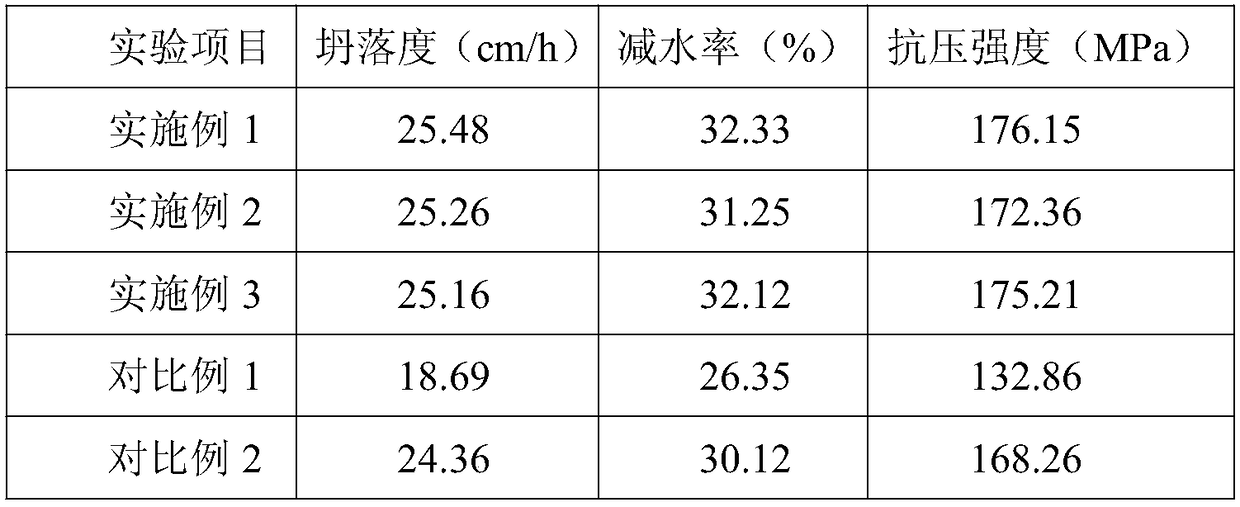

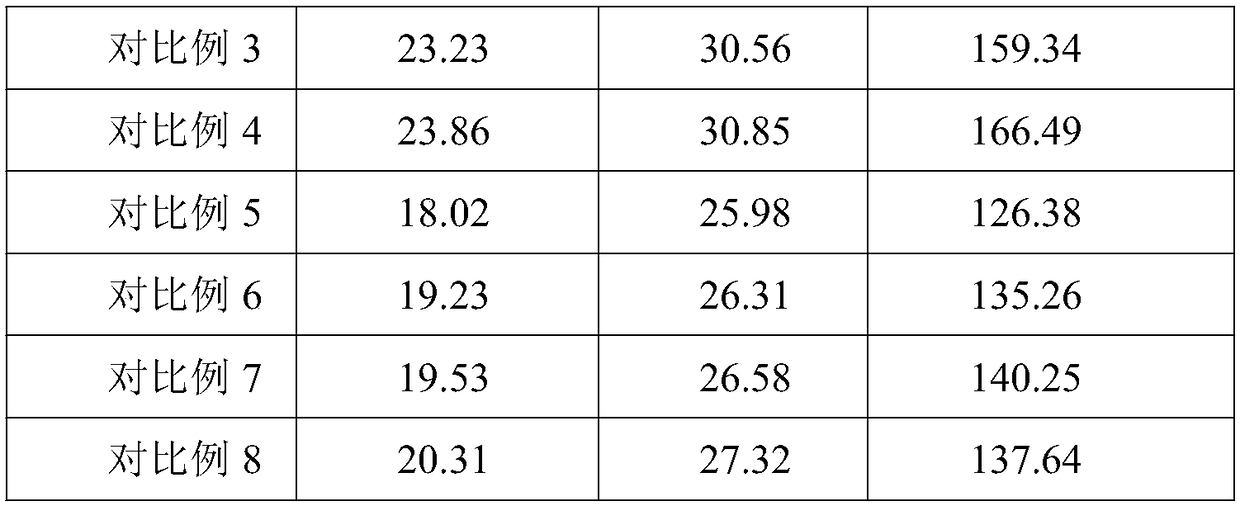

Examples

preparation example Construction

[0027] The preparation method of the polycarboxylic acid water reducer for concrete includes the following steps:

[0028] S1: Take sodium rosinate and phenol in proportion, add sodium hydroxide with a concentration of 20-40% and mix well, adjust the pH to 8.5-10, react at 80-90°C for 1-2h to prepare an initiator solution;

[0029] S2: Dissolve fumaric acid, acrylic acid, polyethylene glycol sodium stearate, sodium methallyl sulfonate and mercaptoethanol in deionized water to prepare an unsaturated sodium carboxylate mother liquor, the dissolution temperature is 60- 80°C;

[0030] S3: In a glass reaction device equipped with a thermometer, agitator, a peristaltic pump dropping device, a nitrogen introduction tube and a reflux cooling device, add deionized water and heat to 55-60°C, and then add methylene according to the raw material ratio Base polyoxyethylene ether, methoxy polyethylene glycol methacrylate, stir and heat to 70-80 ℃ until all dissolved, then add potassium peroxodisu...

Embodiment 1

[0033] A polycarboxylic acid water reducer for concrete, in parts by weight, comprising the following raw materials: 45 parts of methylalkenyl polyoxyethylene ether, 41 parts of methoxy polyethylene glycol methacrylate, and fumaric acid 23 parts, 18 parts of acrylic acid, 25 parts of sodium methallylsulfonate, 1.3 parts of mercaptoethanol, 4.6 parts of potassium peroxodisulfate, 3.5 parts of azobisisobutyronitrile, 1.5 parts of polyethylene glycol sodium stearate, 1 part of sodium rosin and 0.8 part of phenol.

[0034] The preparation method of the polycarboxylic acid water reducer for concrete includes the following steps:

[0035] S1: Take sodium rosinate and phenol in proportion, add 30% sodium hydroxide and mix well, adjust the pH to 9, and react at 90°C for 1 hour to prepare an initiator solution;

[0036] S2: Dissolve fumaric acid, acrylic acid, polyethylene glycol sodium stearate, sodium methallyl sulfonate and mercaptoethanol in deionized water to prepare an unsaturated sodi...

Embodiment 2

[0040] A polycarboxylic acid water-reducing agent for concrete, in parts by weight, comprising the following raw materials: 60 parts of methylalkenyl polyoxyethylene ether, 36 parts of methoxy polyethylene glycol methacrylate, and fumaric acid 20 parts, 15 parts of acrylic acid, 22-28 parts of sodium methallyl sulfonate, 1.6 parts of mercaptoethanol, 3.5 parts of potassium peroxodisulfate, 3.2 parts of azobisisobutyronitrile, 1.2 parts of polyethylene glycol sodium stearate Parts, 0.8 part of sodium rosinate, 0.5 part of phenol.

[0041] The preparation method of the polycarboxylic acid water reducer for concrete includes the following steps:

[0042] S1: Take sodium rosinate and phenol in proportion, add 20% sodium hydroxide and mix well, adjust the pH to 8.5, react at 85°C for 2h to prepare an initiator solution;

[0043] S2: Dissolve fumaric acid, acrylic acid, polyethylene glycol sodium stearate, sodium methallyl sulfonate and mercaptoethanol in deionized water to prepare an uns...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com