Lightweight aggregate concrete containing low-quality recycled aggregate and preparing method thereof

A lightweight aggregate concrete and recycled aggregate technology, applied in the field of lightweight aggregate concrete and its preparation, and macroporous concrete, can solve the problems of poor homogeneity, layered segregation, etc., and achieve low slump loss and strong dispersion , the effect is obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

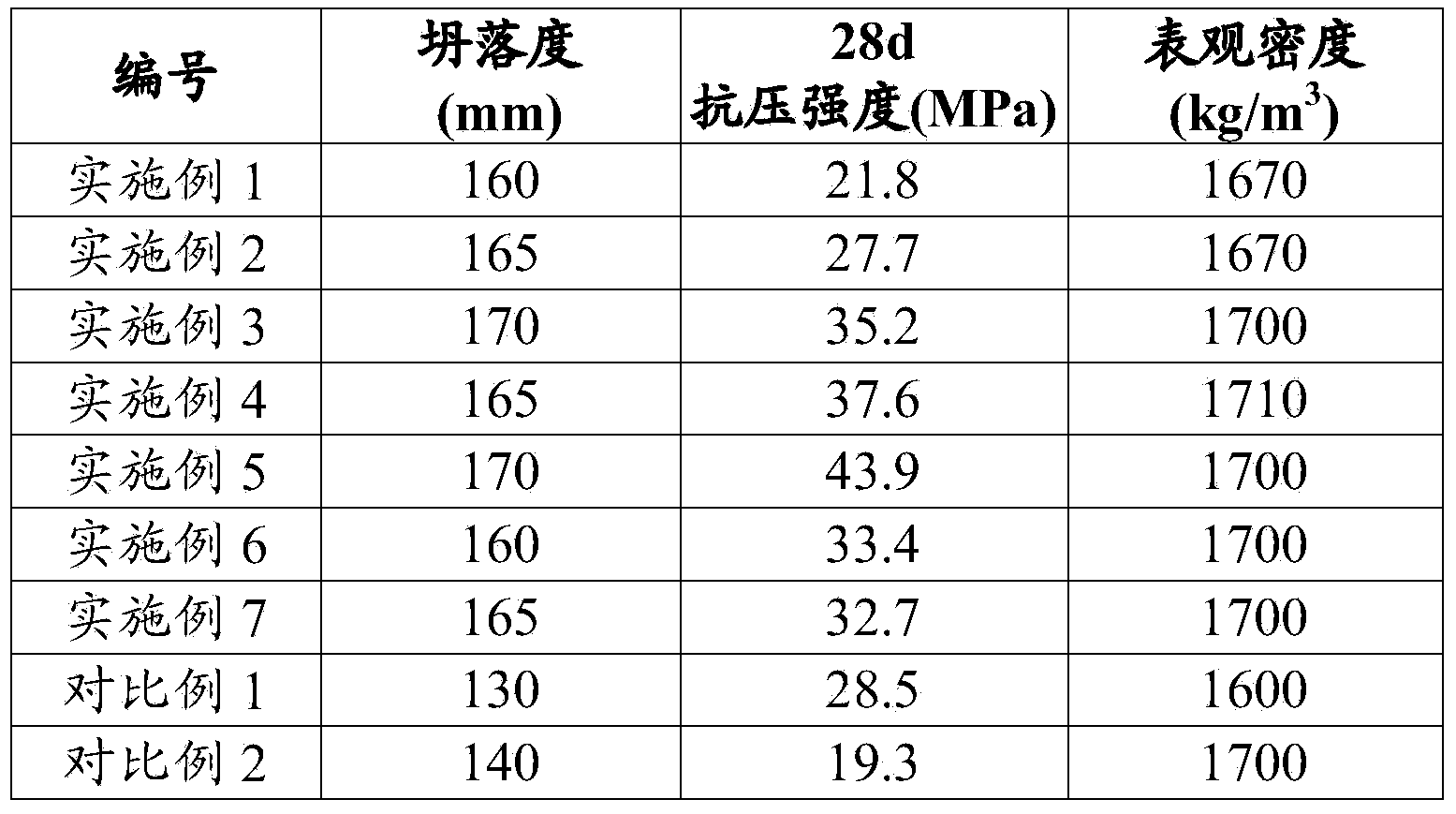

Examples

Embodiment 1

[0038] A lightweight aggregate concrete containing low-quality recycled aggregate, its raw material composition includes, cement 200kg / m 3 , water 170kg / m 3 , additional water 169kg / m 3 , low-quality recycled lightweight fine aggregate 551kg / m 3 , low-quality recycled lightweight coarse aggregate 563kg / m3, mineral powder 40kg / m3 3 , fly ash 60kg / m 3 , Borax 1.50kg / m 3 , sodium polystyrene sulfonate 1.50kg / m 3 , wherein the fineness modulus of the low-quality recycled lightweight fine aggregate is 2.6, and the bulk density is 1200kg / m 3 , the particle size of low-quality recycled lightweight coarse aggregate is 5-16mm, and the bulk density is 700kg / m 3 .

Embodiment 2

[0040] A lightweight aggregate concrete containing low-quality recycled aggregate, its raw material composition includes, cement 220kg / m 3 , water 165kg / m 3 , additional water 166kg / m 3 , low-quality recycled lightweight fine aggregate 532kg / m 3 , low-quality recycled lightweight coarse aggregate 571kg / m 3 , mineral powder 45kg / m 3 , fly ash 55kg / m 3 , sodium fluorosilicate 0.32kg / m 3 , Sodium polystyrene sulfonate 2.24kg / m 3 , wherein the fineness modulus of the low-quality recycled lightweight fine aggregate is 2.7, and the bulk density is 1100kg / m 3 , the particle size of low-quality recycled lightweight coarse aggregate is 5-16mm, and the bulk density is 800kg / m 3 .

Embodiment 3

[0042] A lightweight aggregate concrete containing low-quality recycled aggregate, its raw material composition includes, cement 250kg / m 3 , water 160kg / m 3 , additional water 163kg / m 3 , low-quality recycled lightweight fine aggregate 516kg / m 3 , low-quality recycled lightweight coarse aggregate 579kg / m 3 , mineral powder 50kg / m 3 , fly ash 50kg / m 3 , sodium polyphosphate 3.50kg / m 3 , sodium polystyrene sulfonate 2.8kg / m 3 , wherein the fineness modulus of the low-quality recycled lightweight fine aggregate is 2.8, and the bulk density is 1100kg / m 3 , the particle size of low-quality recycled lightweight coarse aggregate is 5-16mm, and the bulk density is 900kg / m 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com