Sulfonic acid type hydrophilic chain extender and preparation method thereof

A hydrophilic chain extender, sulfonic acid type technology, applied in the field of chemicals and its preparation, can solve the problem of water-based resin heat resistance, acid and alkali resistance and hard water resistance, low carboxyl hydrophilicity, low reactivity, etc. problems, to achieve the effects of acid and alkali resistance and hard water resistance, solid content increase, and high reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

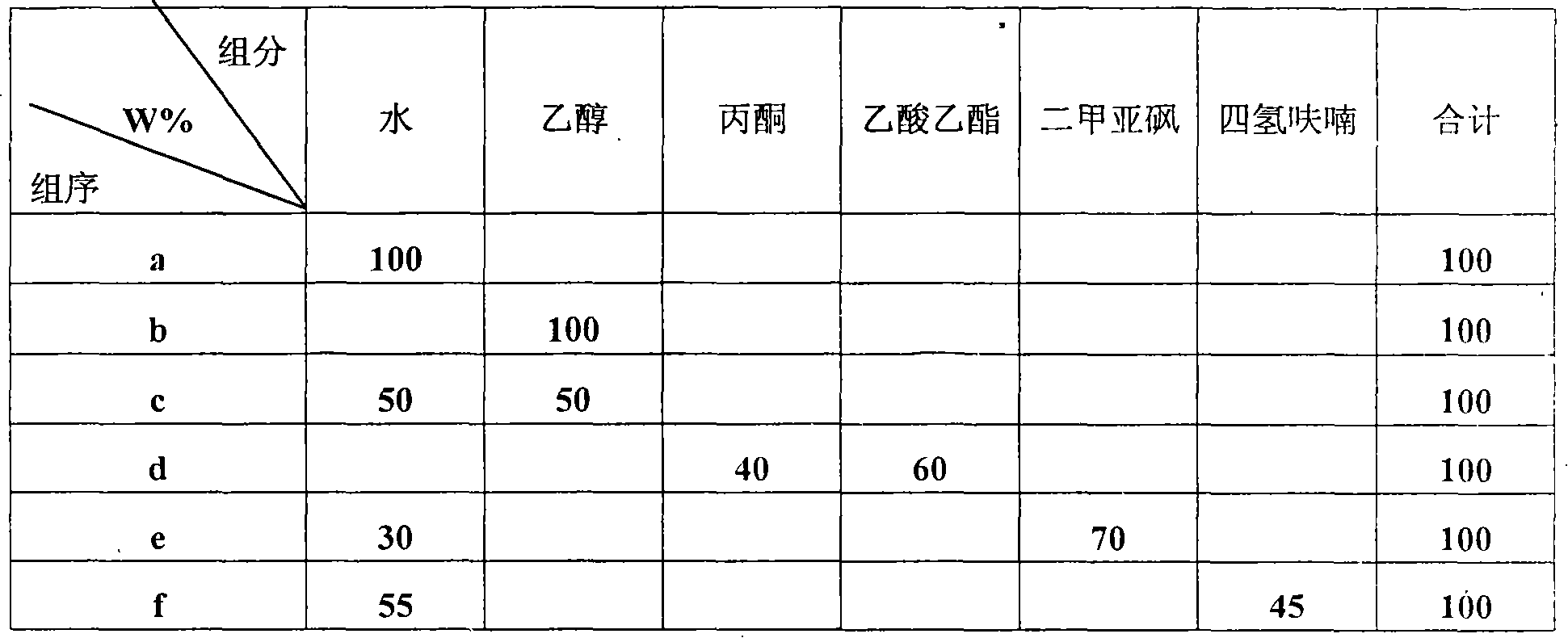

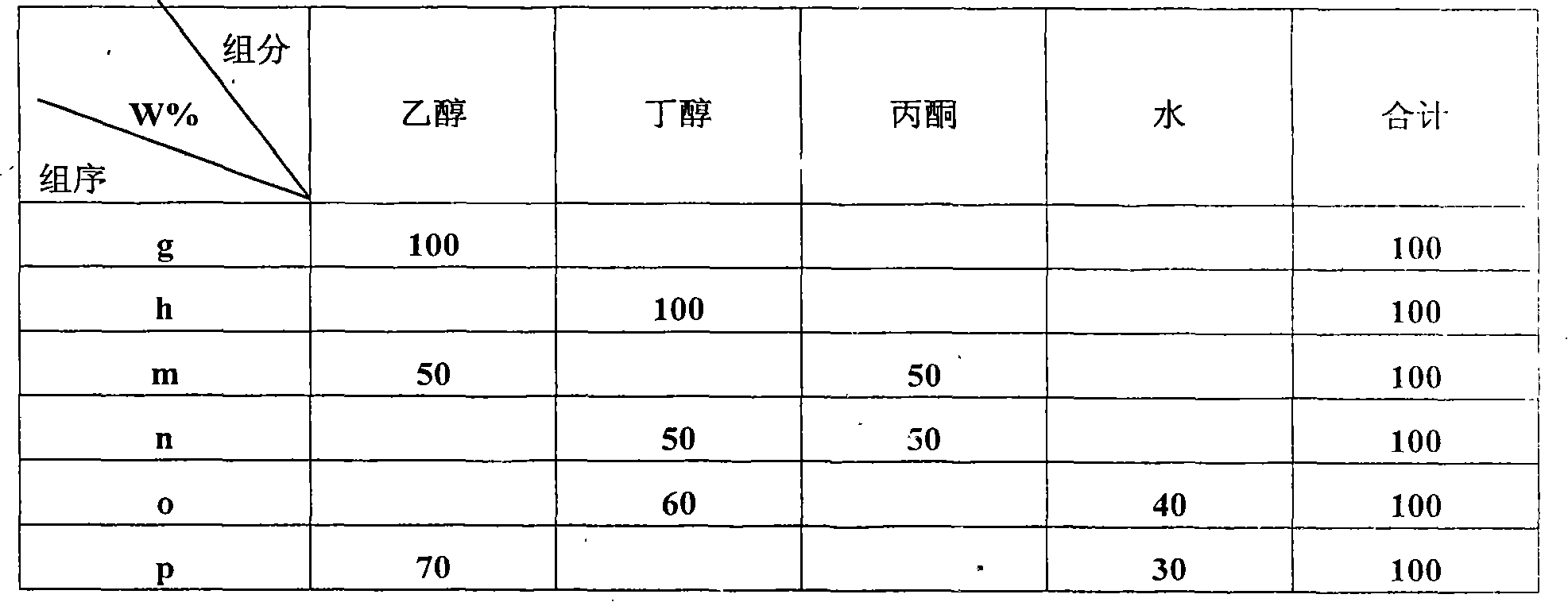

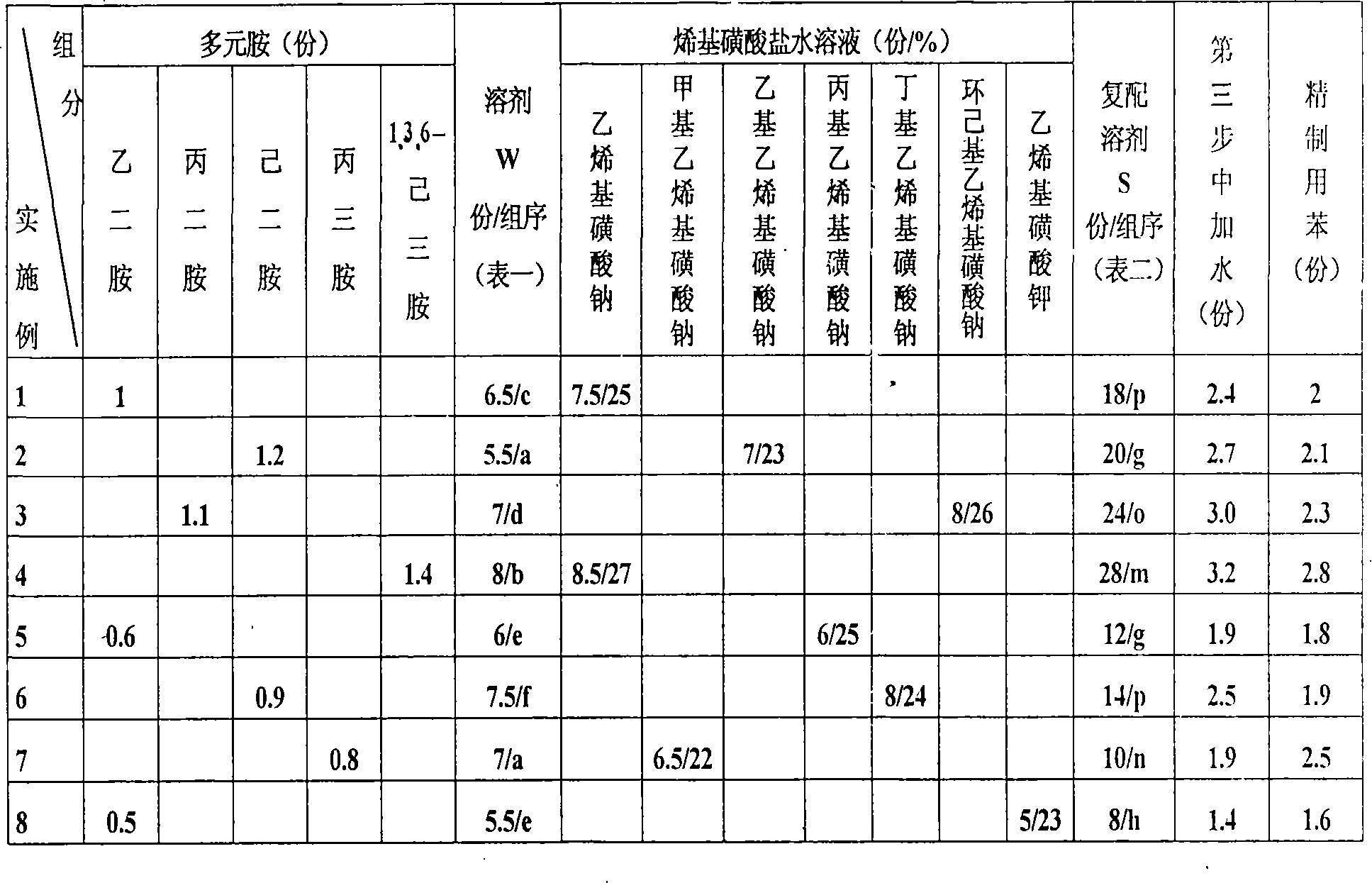

Method used

Image

Examples

Embodiment 1

[0025] The first step is to prepare the initial product, fully dissolve 1 part of ethylenediamine in 6.5 parts of solvent W, solvent W is formed by mixing 50% water and 50% ethanol, and place it in the reactor, and the water bath is heated to 75 ℃, under stirring, uniformly and continuously add 7.5 parts of 25% sodium vinyl sulfonate aqueous solution, and react for 16 hours, stop the reaction, then carry out vacuum distillation to remove the solvent, the pressure is controlled at 0.008MPa, which contains 1.2 parts Remaining water, get the initial product, it is light yellow, oily, viscous liquid with slightly turbid appearance;

[0026] In the second step, the initial product is processed to remove impurities, and the initial product obtained in the first step is completely and fully dissolved in 18 parts of compound solvent S. The compound solvent S is mixed by 70% ethanol and 30% water, fully Stir, and after the insoluble impurities are precipitated and fully aged, filter wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com