Temperature-resistant anionic-nonionic amphoteric hydrophobically associating copolymer and preparation method thereof

A technology of hydrophobic association and copolymer, applied in drilling compositions, chemical instruments and methods, etc., can solve the problem of increasing formation adsorption and oil displacement loss, increasing polymer adsorption and loss, Poor temperature and salt resistance, etc., to achieve the effects of good compatibility, less adsorption, and low shear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

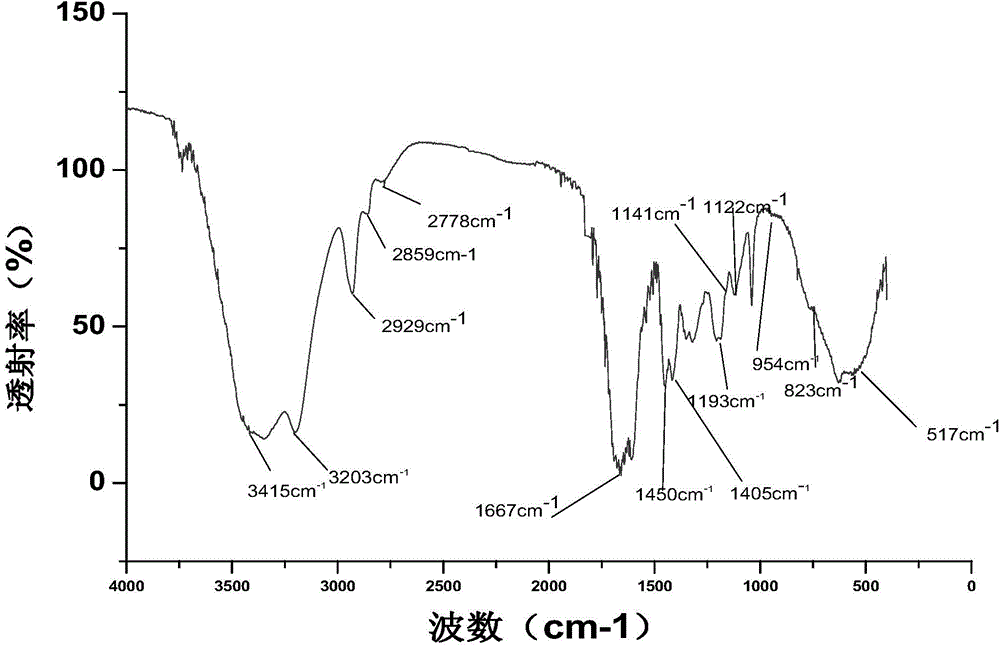

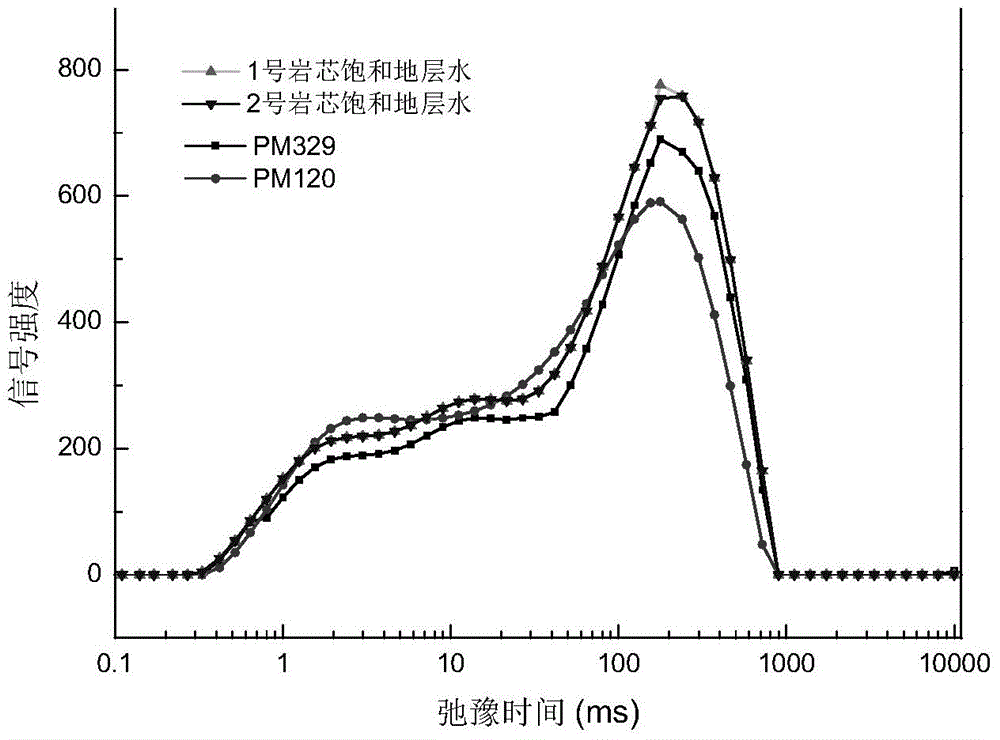

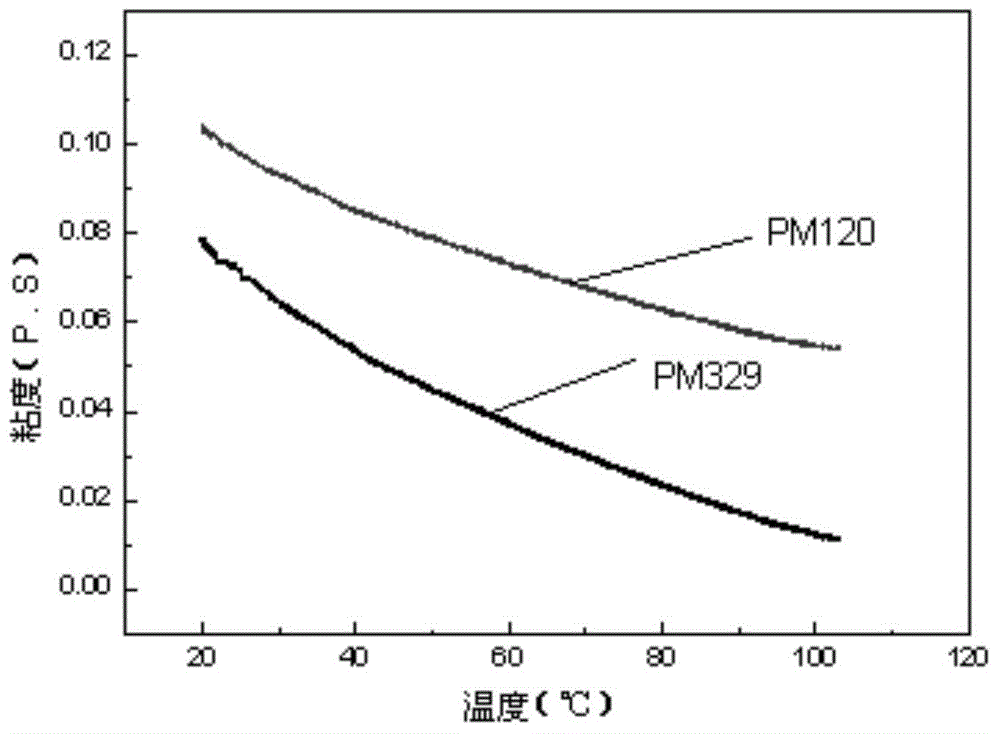

[0041] A temperature-resistant anion-non-amphiteric hydrophobic association copolymer, which is formed by copolymerizing 10g of monomer A, 1g of monomer B and 0.1g of monomer C, monomer A is acrylamide, and monomer B is 2-acrylamide -2-methyl propane sulfonate (AMPS), the monomer C is octadecyl polyoxyethylene methacrylate (OEMA).

[0042] The average molecular weight of the temperature-resistant anisotropic non-amphiteric hydrophobic association copolymer is 1.2 million.

[0043] Preparation:

[0044]1) Weigh 10g of acrylamide (AM), 1g of 2-acrylamide-2-methylpropanesulfonate (AMPS) and 0.1g of octadecyl polyoxyethylene methacrylate (OEMA), dissolve them in 25ml of distilled water, Prepare a mixed solution;

[0045] 2) adding hydrochloric acid with a concentration of 30wt% to adjust the pH value of the mixed solution to 4,

[0046] 3) Add 2.5g sorbitan stearate (Span-60) and 0.3g polyoxyethylene sorbitan monooleate (Tween-80) and 40g cyclohexane to the mixed solution after...

Embodiment 2

[0049] A temperature-resistant, non-amphiphoteric hydrophobic associative copolymer, which is formed by copolymerizing 10g of monomer A, 0.8g of monomer B and 0.08g of monomer C, monomer A is acrylamide, and monomer B is vinyl sulfonate salt, and the monomer C is octadecyl polyoxyethylene methacrylate (OEMA).

[0050] The average molecular weight of the temperature-resistant anisotropic non-amphiteric hydrophobic association copolymer is 1.5 million.

[0051] Preparation:

[0052] 1) Weigh 10g of acrylamide, 0.8g of vinyl sulfonate and 0.08g of octadecyl polyoxyethylene methacrylate (OEMA), and dissolve them in 25ml of distilled water to prepare a mixed solution;

[0053] 2) adding hydrochloric acid with a concentration of 30wt% to adjust the pH value of the mixed solution to 5,

[0054] 3) Add 2.8g sorbitan stearate (Span-60) and 0.2g polyoxyethylene sorbitan monooleate (Tween-80) and 40g cyclohexane to the mixed solution after adjusting the pH value to obtain a mixture , ...

Embodiment 3

[0057] A temperature-resistant anion-non-amphiteric hydrophobic association copolymer, which is formed by copolymerizing 10g of monomer A, 1.2g of monomer B and 0.12g of monomer C, monomer A is acrylamide, and monomer B is 2-propylene Amide-2-methylpropane sulfonate (AMPS), the monomer C is octadecyl polyoxyethylene methacrylate (OEMA).

[0058] The average molecular weight of the temperature-resistant anisotropic non-amphiteric hydrophobic association copolymer is 1.2 million.

[0059] Preparation:

[0060] 1) Weigh 10g of acrylamide, 1.2g of 2-acrylamide-2-methylpropanesulfonate (AMPS) and 0.12g of octadecyl polyoxyethylene methacrylate (OEMA), dissolve them in 25ml of distilled water, and obtain mixture;

[0061] 2) adding hydrochloric acid with a concentration of 30wt% to adjust the pH value of the mixed solution to 6,

[0062] 3) Add 3.2g sorbitan stearate (Span-60) and 0.18g polyoxyethylene sorbitan monooleate (Tween-80) and 40g cyclohexane to the mixed solution after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com