Anion worm-shaped micellar flooding system and preparation method thereof

A technology of worm-like micelles and systems, applied in the field of anionic worm-like micelles flooding system and its preparation, to achieve the effects of low price, overcoming chromatographic separation problems, and simple composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

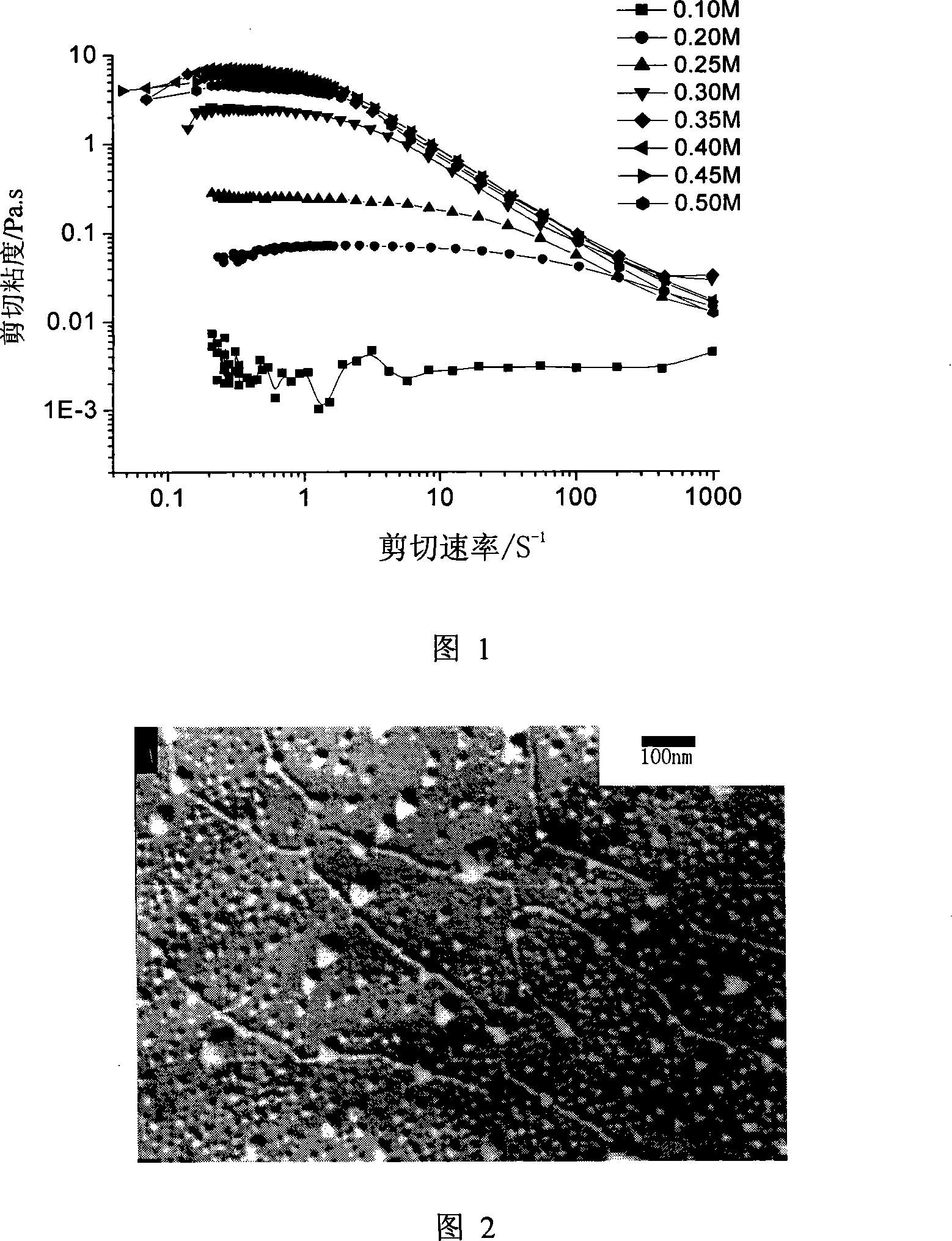

[0026] Example 1: NaOA / Na 2 CO 3 the solution

[0027]1. Preparation of worm-like micellar oil displacement system: Weigh 0.91g of sodium oleate into a 50ml volumetric flask, add 25ml of secondary deionized water, and heat the volumetric flask in a thermostat at 70°C until the oleic acid Dissolve all the sodium; then add 2.12 g of sodium carbonate to the sodium oleate solution, and dilute to the mark with secondary deionized water. And the volumetric flask was placed in a 70°C incubator to continue heating, and the volumetric flask was taken out and oscillated every half an hour. After the sodium carbonate was completely dissolved and the solution was clarified, the volumetric flask could be taken out of the incubator to obtain Vermicular micelles; that is, the worm-like micelles oil flooding system of the following 2(1) formula.

[0028] The amount of sodium oleate was changed respectively, and the following 2 (2), 2 (3) formulations of worm-like micellar oil flooding syst...

Embodiment 2

[0043] Example 2: NaOA / Na 3 PO 4 the solution

[0044] 1. Preparation of worm-like micellar oil displacement system: Weigh 0.91g of sodium oleate into a 50ml volumetric flask, add 25ml of secondary deionized water, and heat the volumetric flask in a thermostat at 70°C until the oleic acid After all the sodium is dissolved, add 3.28 g of Na to the sodium oleate solution 3 PO 4 , dilute to the mark with secondary deionized water, and place the volumetric flask in a 70°C incubator to continue heating. Take out the volumetric flask and tilt it every half hour until the sodium phosphate is completely dissolved and the solution is clarified. The volumetric flask was taken out from the incubator, and the worm-like micelles were obtained; that is, the worm-like micelles oil flooding system of the following 2 (1) formula.

[0045] The amount of sodium oleate was changed respectively, and the worm-like micellar oil flooding system of the following 2 (2) formula was prepared accordin...

Embodiment 3

[0055] Embodiment 3: to NaOA / NaOH / NaCl solution

[0056] 1. Preparation of worm-like micellar oil displacement system: Weigh 0.91g of sodium oleate into a 50ml volumetric flask, add 25ml of secondary deionized water, and heat the volumetric flask in a thermostat at 70°C until the oil After the sodium oleate is completely dissolved, add 0.02g NaOH and 1.17g NaCl to the sodium oleate solution, and the solution needs to be placed at a temperature greater than 20°C.

[0057] 2. Indoor simulated oil displacement experiment:

[0058] Formula: 0.060M NaOA+0.10M NaOH+0.40M NaCl

[0059] Basic data of oil displacement simulation core tube: (experimental temperature 60°C)

[0060] Air permeability: 2.10μm 2 ; Pore volume (PV): 34.50cm 3 ; Saturated oil volume: 27.02cm 3

[0061] Experimental results: water flooding recovery: 68.50% OOIP; chemical flooding recovery: 34.20% OOIP

[0062] It can be seen from the experimental data of the above specific examples that the recovery fact...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com