Polycarboxylic dispersant for oil-well cement and preparation method of polycarboxylic dispersant

A technology of oil well cement and polycarboxylic acid, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of high salt content, poor rheological properties, poor salt resistance, etc., and achieve monomer conversion High efficiency, safe use and easy storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

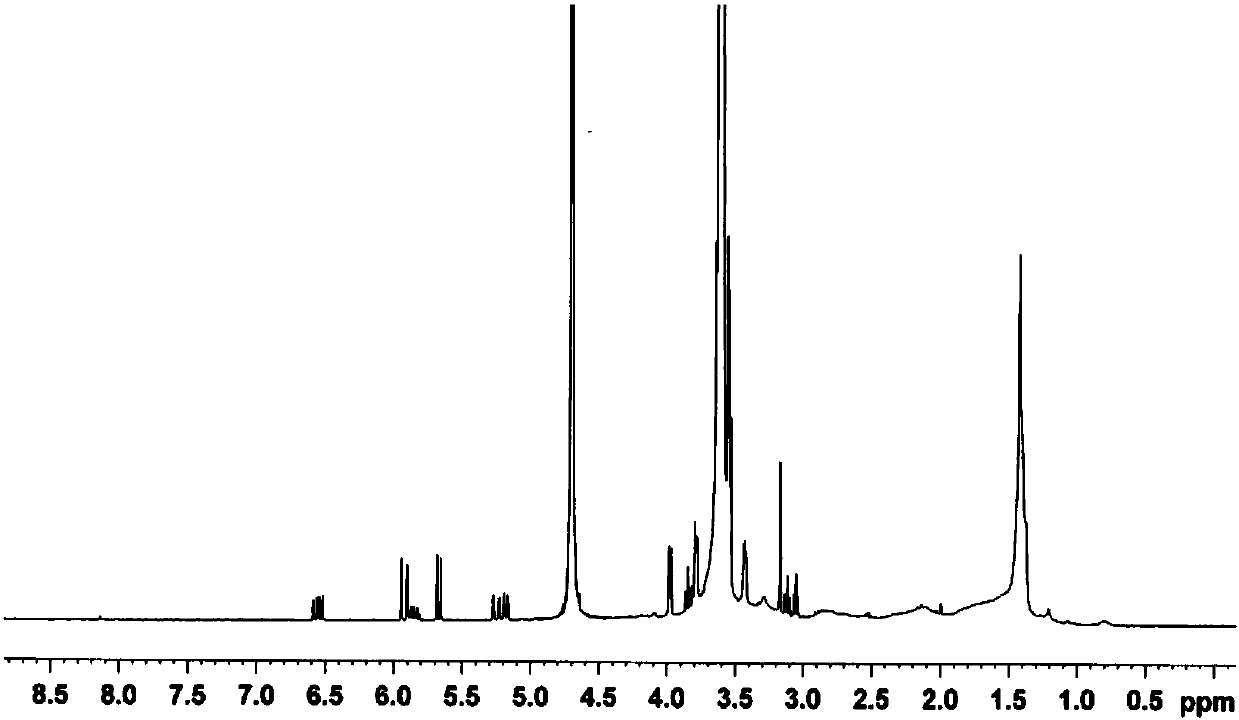

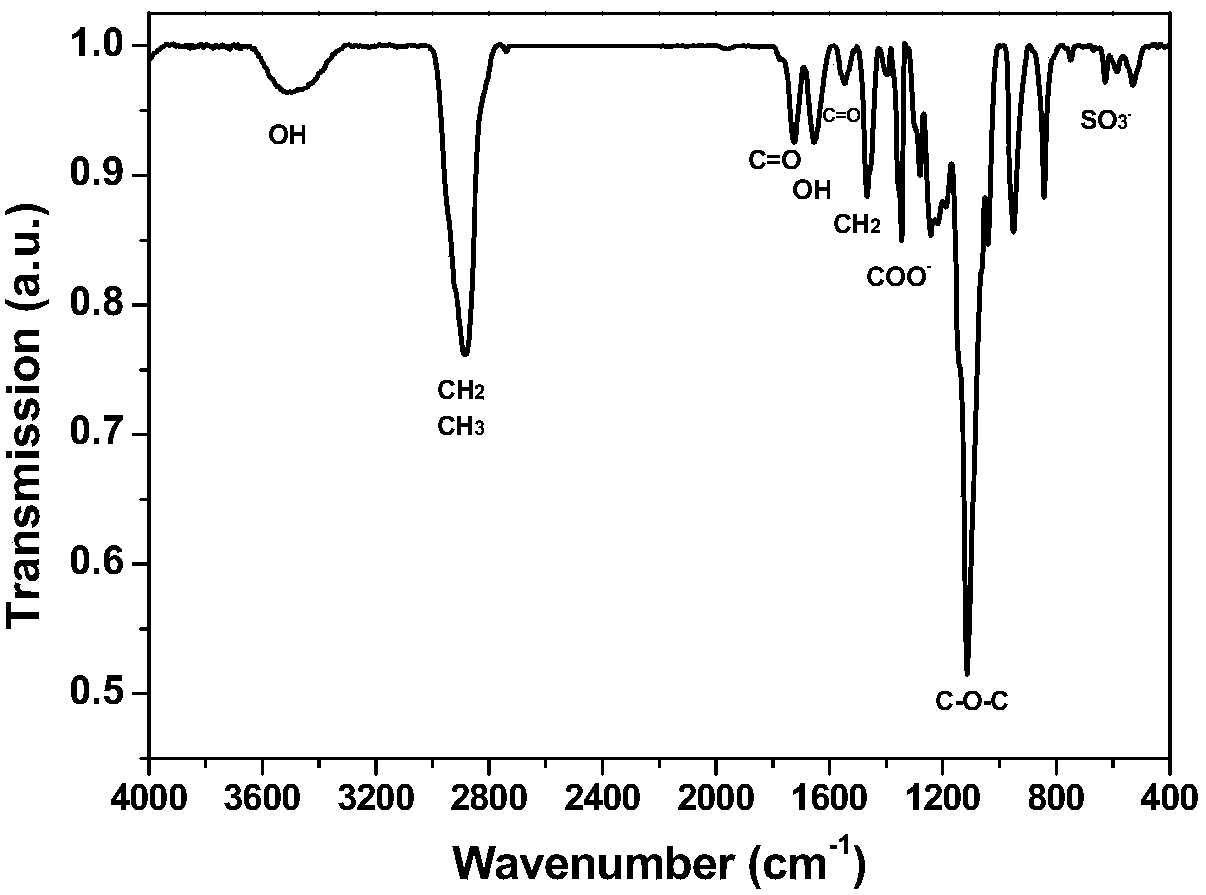

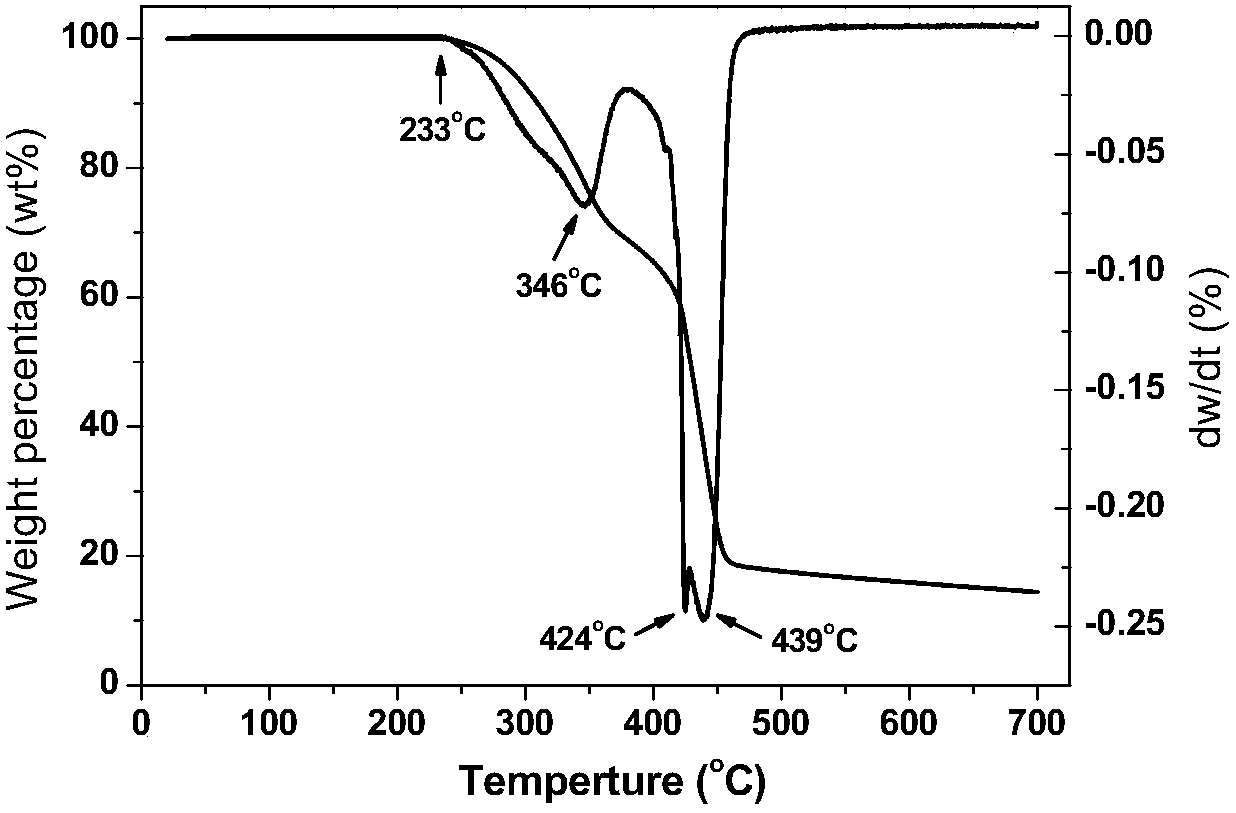

[0050] In the second aspect, the embodiment of the present invention provides a preparation method of the above-mentioned polycarboxylic acid dispersant. The monomers of the above-mentioned polycarboxylic acid dispersant are highly reactive ethylenic monomers, so the above-mentioned polycarboxylic acid dispersant can be prepared by free radical polymerization. At the same time, since the above-mentioned monomers are all water-soluble monomers, the polymerization method can be aqueous solution polymerization, and a water-soluble initiator is used to initiate the polymerization reaction. An optional preparation method is as follows, comprising the following steps:

[0051] Step 1, add 2-acrylamido-2-methylpropanesulfonic acid monomer, acrylic acid monomer, N-vinylpyrrolidone monomer, itaconic acid monomer, sodium vinylsulfonate monomer, ethylene sodium base benzene sulfonate monomer and allyl polyethylene glycol monomer; wherein, the weight average molecular weight of allyl pol...

Embodiment 1

[0077] This embodiment provides a polycarboxylic acid dispersant for oil well cement. Base-2-methylpropanesulfonic acid, sodium vinylsulfonate, sodium vinylbenzenesulfonate and APEG-2100 are copolymers of monomers.

[0078] The preparation method of this polycarboxylic acid dispersant comprises the following steps:

[0079] Step 101, at room temperature, add 400ml of water to a four-necked flask equipped with a stirrer, a nitrogen pipe, a vent pipe and a thermometer, and then add 1g of acrylamide and 20g of 2-acrylamido-2-methylpropanesulfonate to the water in sequence acid, 2g acrylic acid, 3g maleic anhydride, 3.5g N-vinylpyrrolidone, 4g itaconic acid, 10g sodium vinylsulfonate, 4g sodium vinylbenzenesulfonate, and 70g APEG-2100. After each monomer is added, the reaction system is stirred at room temperature until the monomer is completely dissolved before adding the next monomer.

[0080] Step 102, using sodium hydroxide to adjust the pH value of the reaction system obtai...

Embodiment 2

[0102] This embodiment provides a polycarboxylic acid dispersant for oil well cement. Base-2-methylpropanesulfonic acid, sodium vinylsulfonate, sodium vinylbenzenesulfonate and APEG-2100 are copolymers of monomers.

[0103] The preparation method of this polycarboxylic acid dispersant comprises the following steps:

[0104] Step 201, at room temperature, add 400ml of water to a four-neck flask equipped with a stirrer, a nitrogen pipe, a vent pipe and a thermometer, and then add 1g of acrylamide and 30g of 2-acrylamido-2-methylpropanesulfonate to the water in sequence acid, 3 g acrylic acid, 3 g maleic anhydride, 3.5 g N-vinylpyrrolidone, 4 g itaconic acid, 10 g sodium vinyl sulfonate, 4 g sodium vinyl benzene sulfonate, and 70 g APEG-2100. After each monomer is added, the reaction system is stirred at room temperature until the monomer is completely dissolved before adding the next monomer.

[0105] Step 202, using sodium hydroxide to adjust the pH value of the reaction syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com