Method for preparing silica/silver nuclear shell structure granules by using polyvinyl pyrrolidone (PVP) in an assistant way

A silica and shell structure technology, applied in nanostructure manufacturing, nanotechnology, nanotechnology and other directions, can solve the problems of easy agglomeration of particles, difficult to adjust the absorption peak of core-shell structure, complicated preparation methods, etc., to achieve catalytic chemical reaction, Enhanced Raman scattering and enhanced dye luminescence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

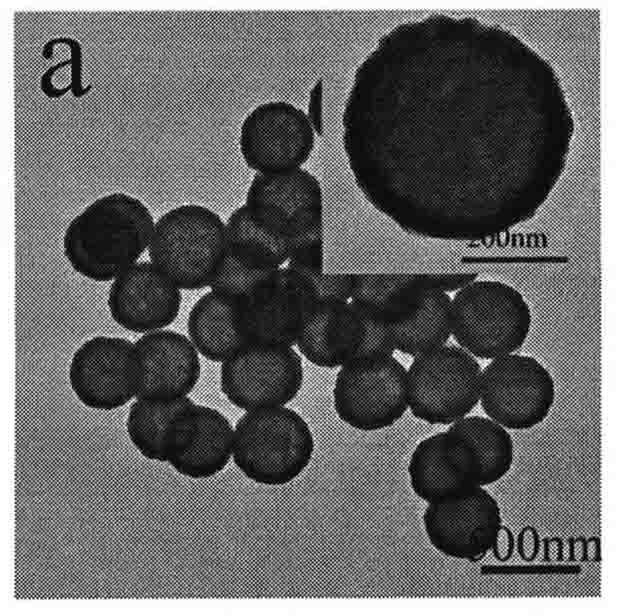

[0020] Add 0.1 g of silica spheres with a diameter of 300 nm to 10 ml of water for ultrasonic dispersion for 20 minutes, add to 10 ml of 3% SnCl 2 2H 2 O in a dilute hydrochloric acid solution (add 100 microliters of 37% concentrated hydrochloric acid) and stir for 30 minutes, centrifuge and wash with deionized water 5 times, and disperse into 5 milliliters of water. Under ultrasonic conditions, add the sphere liquid to 15 ml of 0.35 mol / L silver ammonia solution and react for 20 minutes. A layer of small silver particles grow on the surface of the silica sphere, which is centrifugally cleaned and dispersed into 10 ml of ethanol. Add 1 gram of PVP to 220 milliliters of water and stir to dissolve, add 0.5 milliliters of 1 mol / liter silver nitrate aqueous solution, prepare 3 parts of this solution, add 0.2 milliliters and 0.4 milliliters of silica ball solutions with small silver particles on the surface, respectively, 0.8 milliliters, then add 0.2 milliliters of formaldehyde, ...

Embodiment 2

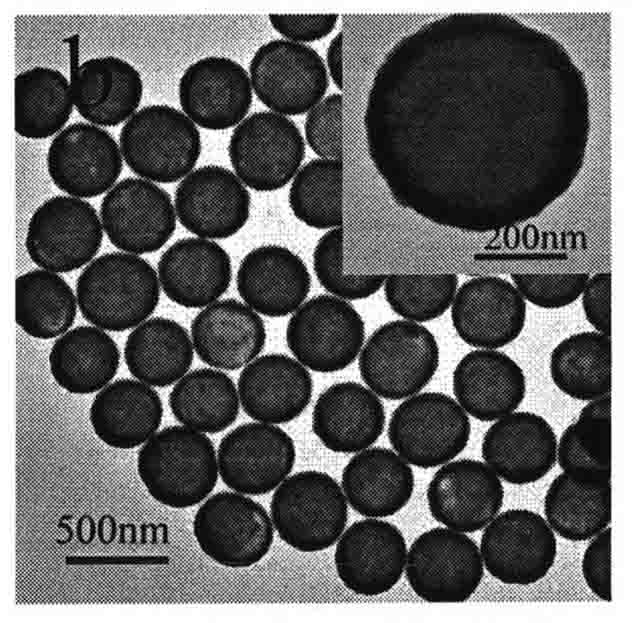

[0026] Add 0.1 g of silica spheres with a diameter of 1000 nm to 10 ml of water for ultrasonic dispersion for 20 minutes, add to 10 ml of 3% SnCl 2 2H 2 O in a dilute hydrochloric acid solution (add 100 microliters of 37% concentrated hydrochloric acid) and stir for 30 minutes, centrifuge and wash with deionized water 5 times, and disperse into 5 milliliters of water. Under ultrasonic conditions, add the sphere liquid to 15 ml of 0.35 mol / L silver ammonia solution and react for 20 minutes. A layer of small silver particles grow on the surface of the silica sphere, which is centrifugally cleaned and dispersed into 10 ml of ethanol. Add 1 g of PVP to 220 ml of water and stir to dissolve, add 0.5 ml of 1 mol / L silver nitrate aqueous solution, and prepare 3 equal parts of this solution. Add 0.2 milliliters, 0.4 milliliters, and 0.8 milliliters of silica sphere solutions with small silver particles on the surface, then add 0.2 milliliters of formaldehyde and 0.4 milliliters of amm...

Embodiment 3

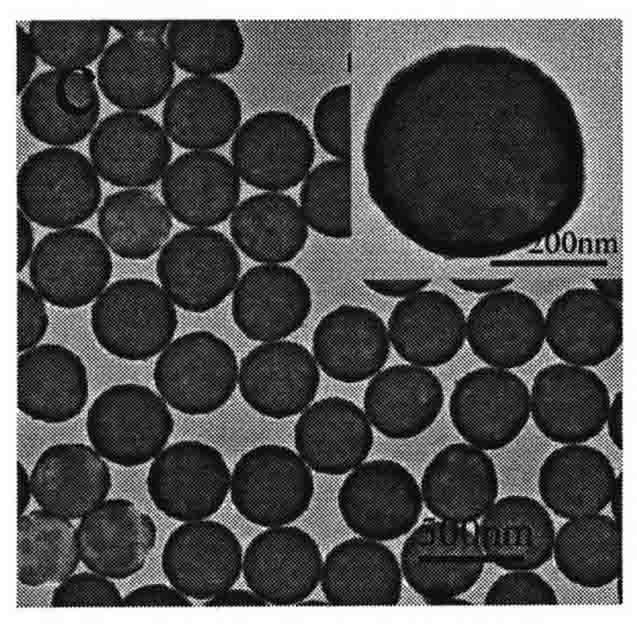

[0028] Add 0.1 g of silica spheres with a diameter of 300 nm to 10 ml of water for ultrasonic dispersion for 20 minutes, add to 10 ml of 3% SnCl 2 2H 2 O in a dilute hydrochloric acid solution (add 100 microliters of 37% concentrated hydrochloric acid) and stir for 30 minutes, centrifuge and wash with deionized water 5 times, and disperse into 5 milliliters of water. Under ultrasonic conditions, add the sphere liquid to 15 ml of 0.35 mol / L silver ammonia solution and react for 20 minutes. A layer of small silver particles grow on the surface of the silica sphere, which is centrifugally cleaned and dispersed into 10 ml of ethanol. Add 0.5 g of PVP to 220 ml of water and stir to dissolve, add 0.5 ml of 1 mol / L silver nitrate aqueous solution, and prepare 3 equal parts of this solution. Add 0.2 milliliters, 0.4 milliliters, and 0.8 milliliters of silica sphere solutions with small silver particles on the surface, then add 0.2 milliliters of formaldehyde and 0.4 milliliters of am...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com