Bismuth oxybromide particles with three-dimensional flower-like microstructure and preparation method and use thereof

A microstructure, three-dimensional flower-like technology, applied in chemical instruments and methods, inorganic chemistry, bismuth compounds, etc., can solve problems such as low specific surface area, limited microstructure adjustability, and easy aggregation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 0.12g bismuth nitrate pentahydrate (2.47×10 -4 mol) into a mixed solution of 5.0mL ethylene glycol and 35.0mL isopropanol, and stir to fully dissolve it. Then add 0.18g cetyltrimethylammonium bromide (4.94×10 -4 mol), and stirred until the solution was clear. The obtained transparent solution was put into a polytetrafluoroethylene-lined stainless steel reactor, keeping the volume of the solution at 80% of the total volume of the reactor, and placed in an oven at 160° C. for 12 hours. After the reaction is completed, let the reactor cool down to 25°C naturally, and a yellow powder can be obtained. The powder was centrifuged, rinsed three times with deionized water, and then oven dried at 80°C. Then put the sample into a crucible, and bake it in a muffle furnace at 400° C. for 4 hours under air, and then obtain bismuth oxybromide particles with a three-dimensional flower-like microstructure.

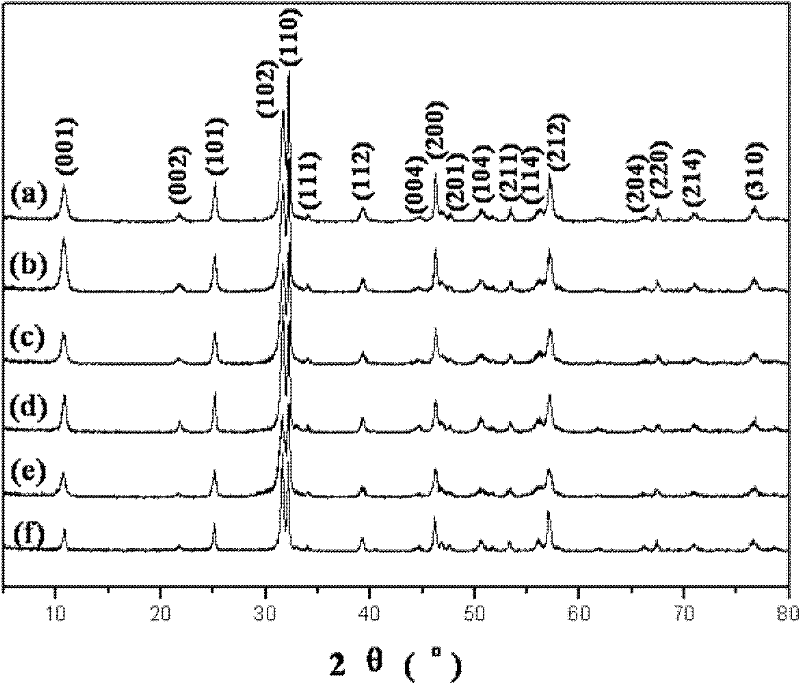

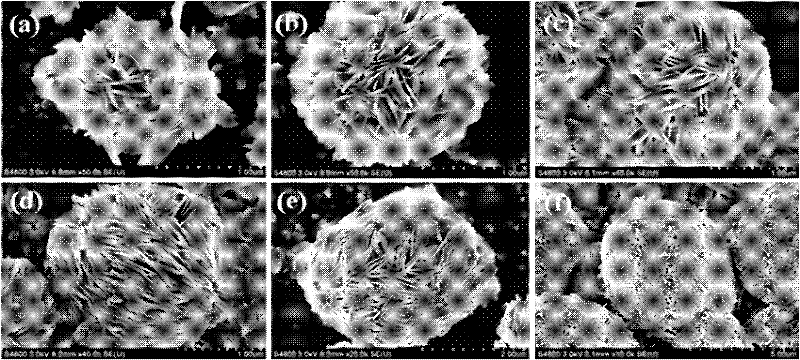

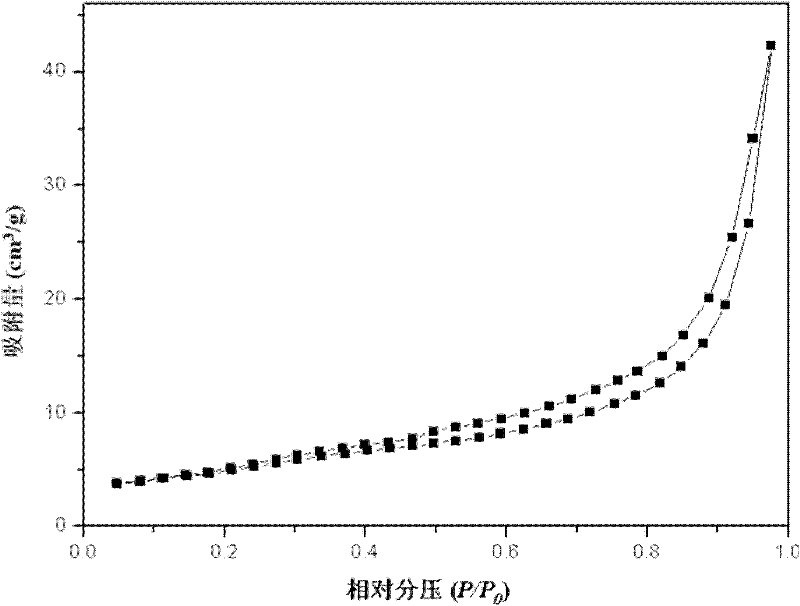

[0025] figure 1 The X-ray diffraction spectrum of the product of this embo...

Embodiment 2

[0027]Add 0.12 g of bismuth nitrate pentahydrate into a mixed solution of 2.0 mL of ethylene glycol and 38.0 mL of isopropanol, and stir to fully dissolve it. Then 0.18 g of cetyltrimethylammonium bromide was added. The obtained transparent solution was put into a polytetrafluoroethylene-lined stainless steel reactor, keeping the volume of the solution at 80% of the total volume of the reactor, and placed in an oven at 160° C. for 12 hours. After the reaction is completed, let the reactor cool down to 25°C naturally, and a yellow powder can be obtained. The powder was centrifuged, rinsed three times with deionized water, and then oven dried at 80°C. Then put the sample into a crucible, and bake it in a muffle furnace at 400° C. for 4 hours under air, and then obtain bismuth oxybromide particles with a three-dimensional flower-like microstructure.

[0028] figure 1 The X-ray diffraction spectrum of the product of this embodiment is consistent with JCPDS#93-0393, proving that...

Embodiment 3

[0030] Add 0.12 g of bismuth nitrate pentahydrate into a mixed solution of 10.0 mL of ethylene glycol and 30.0 mL of isopropanol, and stir to fully dissolve it. Then 0.18 g of cetyltrimethylammonium bromide was added. The obtained transparent solution was put into a polytetrafluoroethylene-lined stainless steel reactor, keeping the volume of the solution at 80% of the total volume of the reactor, and placed in an oven at 160° C. for 12 hours. After the reaction is completed, let the reactor cool down to 25°C naturally, and a yellow powder can be obtained. The powder was centrifuged, rinsed three times with deionized water, and then oven dried at 80°C. Then put the sample into a crucible, and bake it in a muffle furnace at 400° C. for 4 hours under air, and then obtain bismuth oxybromide particles with a three-dimensional flower-like microstructure.

[0031] figure 1 The X-ray diffraction spectrum of the product of this embodiment is consistent with JCPDS#93-0393, proving th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com