Novel metallic material

A new type of metal material and metal material technology, applied in the field of metal material production, can solve the problem of expensive rare earth elements and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] According to a new type of metal material in this embodiment, the metal material includes the following weight components:

[0022] C: 0.9%, Si: 1.0%, Mn: 1.5%, Ni: 5.0%, Cr: 21%, Cu: 1.8%, Al: 0.3%, Ti: 0.6%, La: 0.4%, Sn: 0.8%; The rest is Fe,

[0023] Dosing according to the ratio of the materials, put the prepared materials into the smelting furnace to heat and melt, pour at 1500-1650°C after melting, cool to 920-950°C and put them in the incubator to cool to room temperature, and finally at 450°C ℃~500℃ for tempering treatment.

Embodiment 2

[0025] According to a new type of metal material in this embodiment, the metal material includes the following weight components:

[0026] C: 1.5%, Si: 0.8%, Mn: 1.5%, Ni: 4.5%, Cr: 18%, Cu: 1.5%, Al: 0.6%, Ti: 0.5%, Ce: 0.4%, Sn: 1.2%; The rest is Fe,

[0027] Dosing according to the ratio of the materials, put the prepared materials into the intermediate frequency furnace to heat and melt, pour at 1500-1650°C after melting, cool to 920-950°C and put them in the incubator to cool to room temperature, and finally at 450°C ~500℃ for tempering treatment.

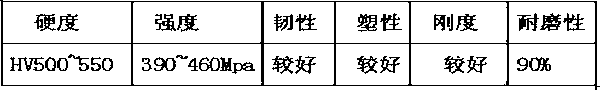

[0028] The mechanical properties of the metal material prepared by the above method are as follows:

[0029] .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com