Preparation method of beta-type bismuth oxide

A technology of bismuth oxide and bismuth nitrate, applied in chemical instruments and methods, inorganic chemistry, bismuth compounds, etc., can solve the problems of easy substitution of impurities, easy agglomeration of powder, uneven particle size distribution, etc., to achieve high purity and reduce synthesis Effect of temperature, nodule rate stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

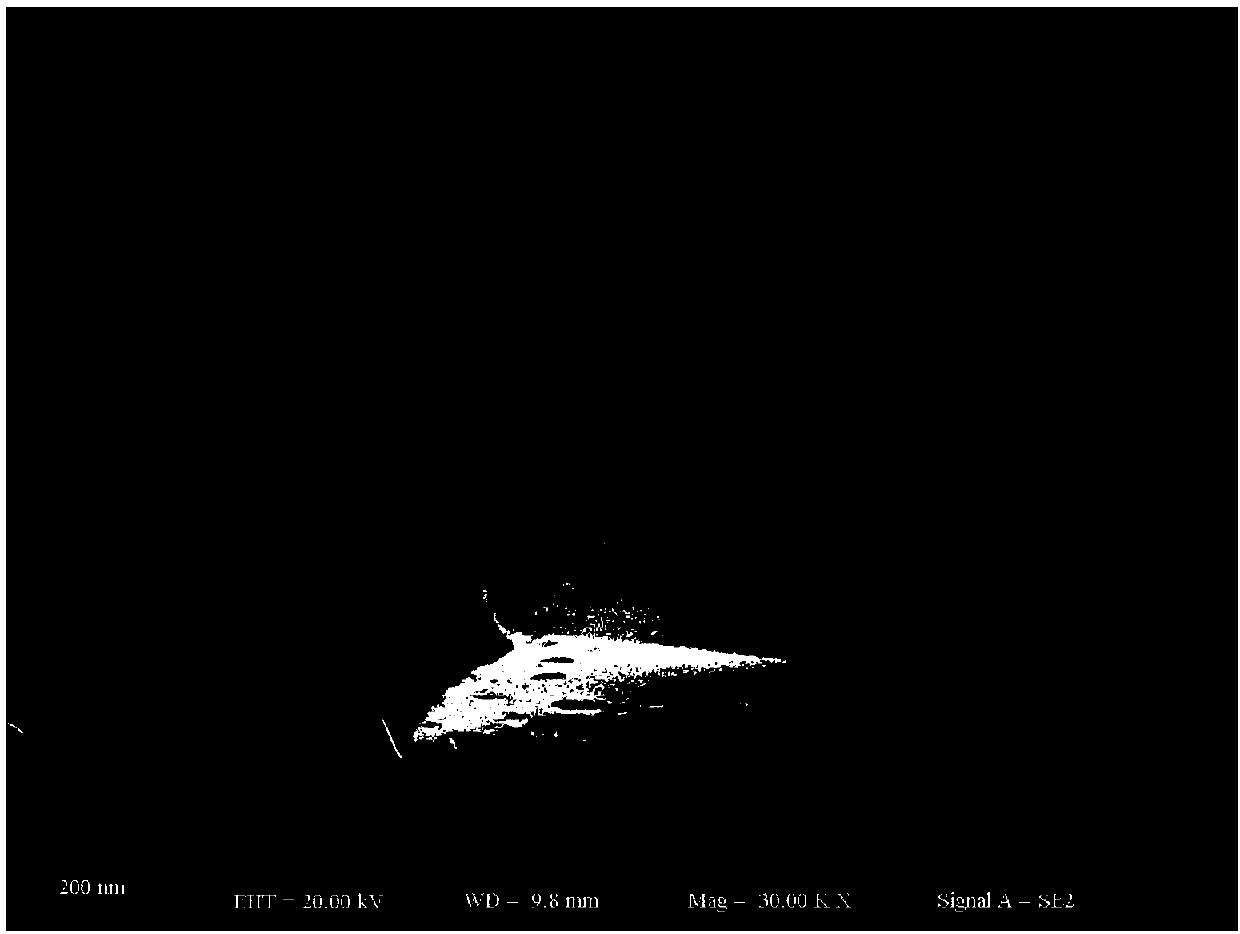

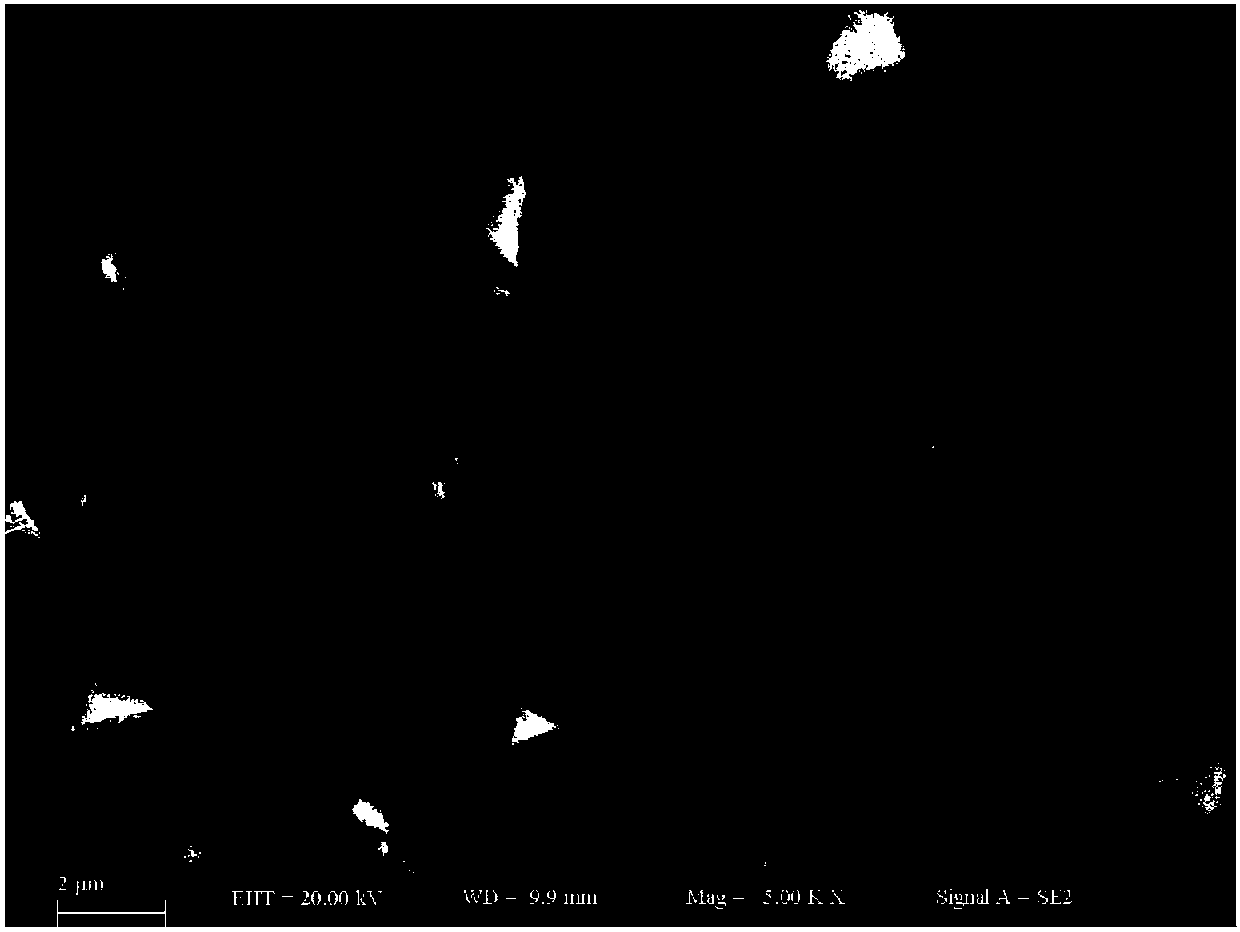

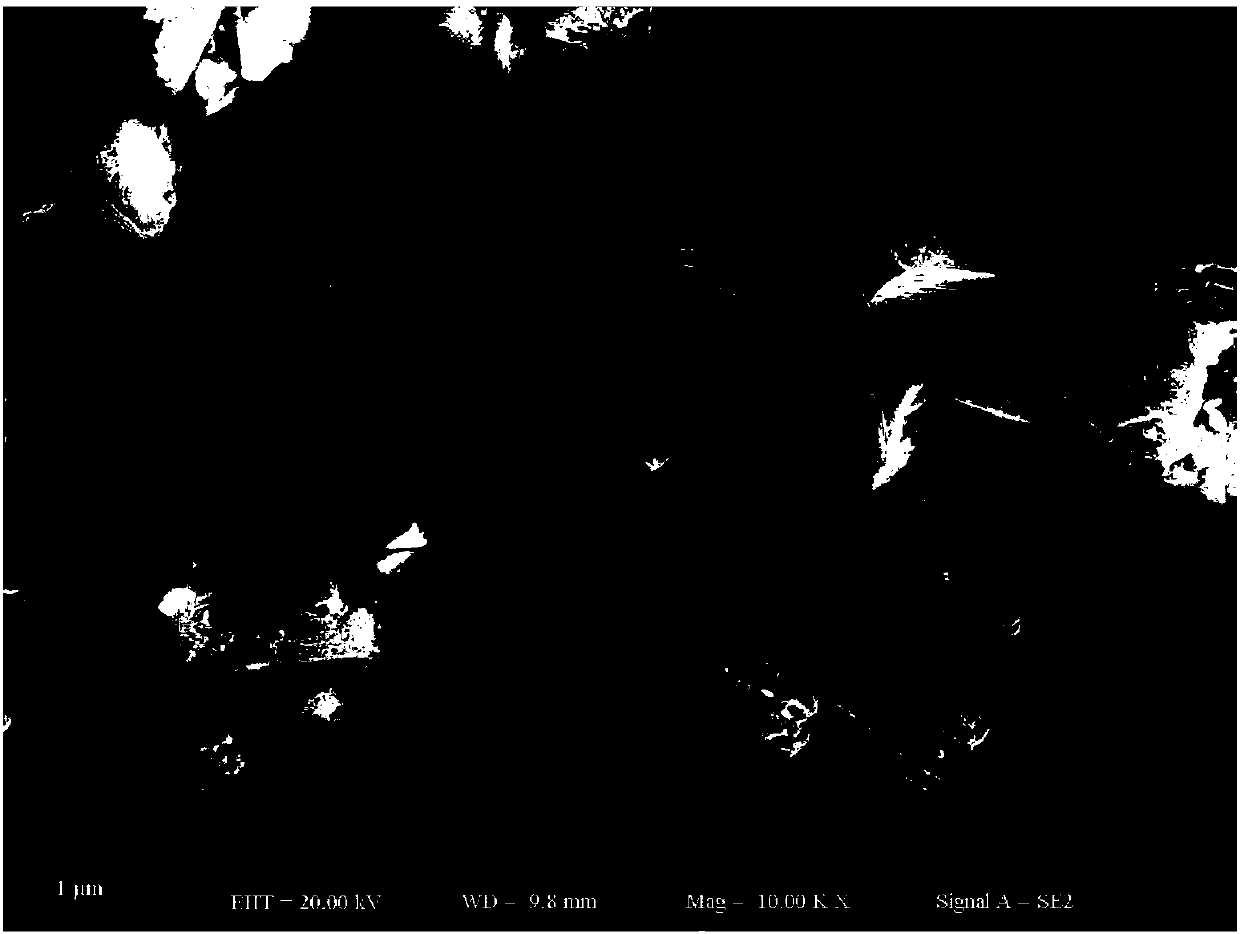

Image

Examples

Embodiment 1

[0043] A kind of preparation method of bismuth oxide, adopts following steps:

[0044] (1), 0.05mol Bi(NO 3 ) 3 ·5H 2 O was added to 50.0ml of nitric acid solution with a concentration of 2mol / L, stirred, and the bismuth nitrate was fully dissolved and dispersed;

[0045] (2), weighing 0.005 g of anionic surfactant polyacrylamide, adding polyacrylamide to (1) bismuth nitrate solution, and stirring evenly; wherein, the particle diameter of polyacrylamide is 60 mesh to 80 mesh;

[0046] (3), the alcohol ether phosphate of 0.5ml is dripped in the sodium hydroxide solution that 50ml concentration is 2mol / L, after stirring and mixing, add in the solution of step (2) again, stir and mix again, use 2mol / L After the nitric acid or sodium hydroxide solution of L adjusts the pH value to 8, as the bismuth oxide precursor reflux liquid,

[0047] (4) Place the reflux liquid of the above-mentioned bismuth oxide precursor in a reflux device composed of a three-necked flask and a condense...

Embodiment 2

[0051] A kind of preparation method of bismuth oxide, adopts following steps:

[0052] (1), 0.1mol Bi(NO 3 ) 3 ·5H 2 O was added to 50.0ml of nitric acid solution with a concentration of 1.5mol / L, stirred at 500r / min, and stirred for 3min to fully dissolve and disperse the bismuth nitrate;

[0053] (2), weighing 0.01 g of anionic surfactant polyacrylamide, adding polyacrylamide into (1) bismuth nitrate solution, stirring speed is 500r / min, stirring for 3min, and mixing evenly; wherein, the particle size of polyacrylamide The diameter is 60 mesh to 80 mesh;

[0054] (3), 50ml concentration is that the potassium hydroxide solution of 3mol / L drops into the alcohol ether phosphate of 0.5ml, stirring speed is 500r / min, 3min mixes, add the solution of step (2), stirring speed is 500r / min min, after stirring for 5 minutes, and then adjusting the pH value to 10 with nitric acid and sodium hydroxide solution, as the reflux liquid of the bismuth oxide precursor,

[0055] (4), the a...

Embodiment 3

[0059] A kind of preparation method of bismuth oxide, adopts following steps:

[0060] (1), 0.075mol Bi(NO 3 ) 3 ·5H 2 O was added to 50.0ml of nitric acid solution with a concentration of 3mol / L, stirred, and the bismuth nitrate was fully dissolved and dispersed;

[0061] (2), weighing 0.03 g of anionic surfactant polyacrylamide, adding polyacrylamide to (1) bismuth nitrate solution, and stirring evenly; wherein, the particle diameter of polyacrylamide is 60 mesh to 80 mesh;

[0062] (3), drop 50ml of potassium hydroxide solution with a concentration of 2mol / L into 1ml of alcohol ether phosphate, stir and mix, then add in the solution of step (2), stir and mix, use nitric acid and sodium hydroxide After the pH value of the solution is adjusted to 11, as the reflux liquid of the bismuth oxide precursor,

[0063] (4) Place the above-mentioned bismuth oxide precursor reflux liquid in a reflux device composed of a three-necked flask and a condenser tube. The reflux device is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com