Prepn process of nanometer BN and B-C-N capsule or nanometer fullerene-like particle

A technology of nanoparticles and nanocapsules, which is applied in the new synthesis field of novel nanostructures, can solve problems such as difficulty in separation, mixed shape of BN nanostructures, and influence on the application prospects of materials, and achieve the effect of high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

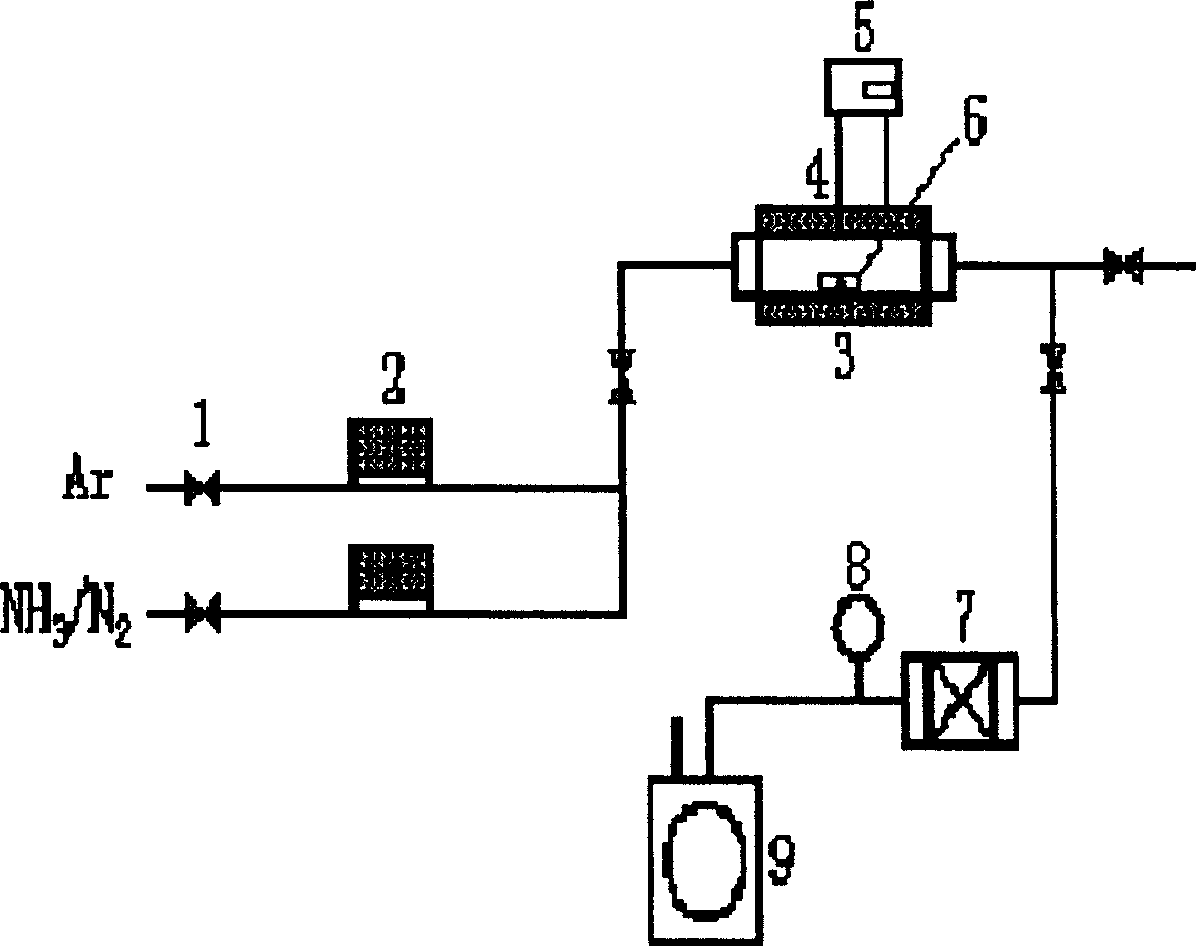

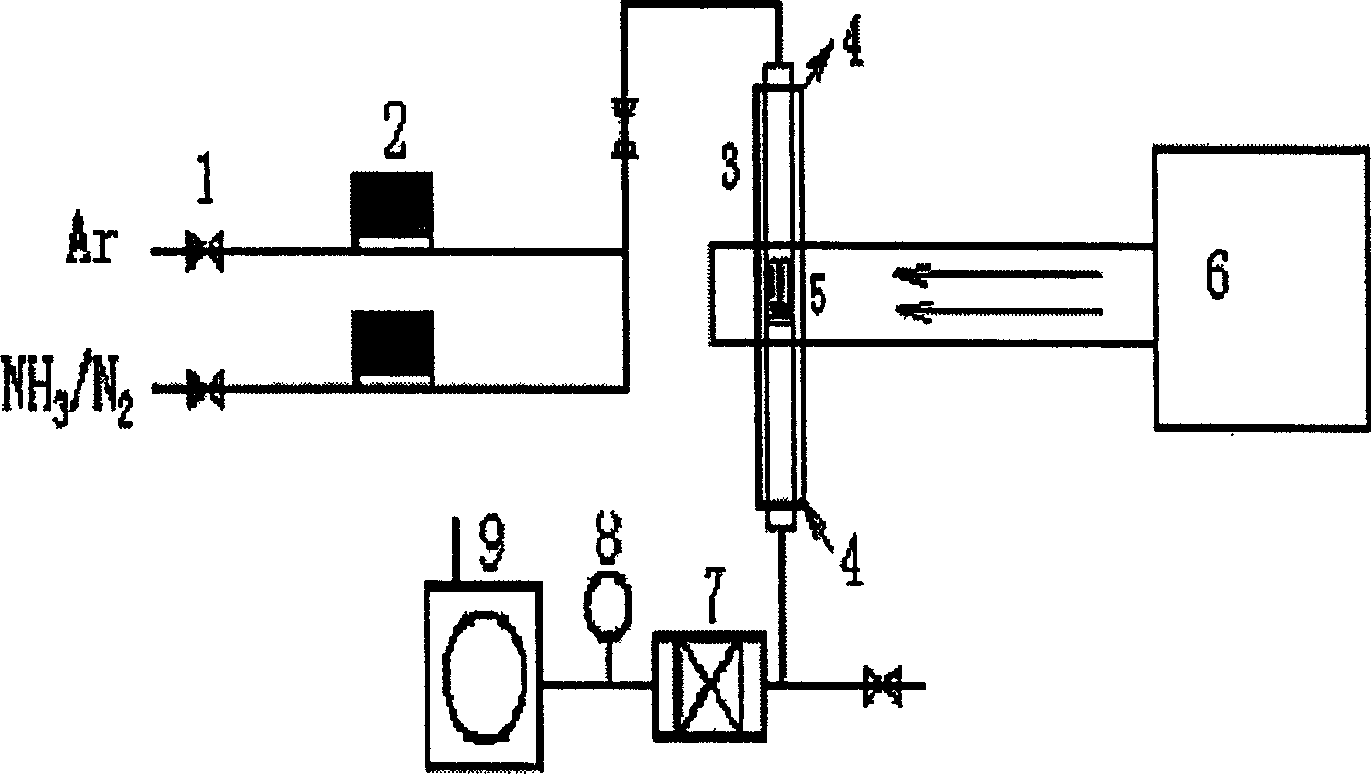

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1: with Fe 75 B 25 Nanoparticle catalysts prepared BN nanocapsules at 850 °C.

[0045] From 1mol / L KBH 4 With 0.1mol / L FeSO 4 Liquid-phase reaction produces Fe with an average particle size of about 40 nanometers 75 B 25 nanoparticles. The obtained Fe-B nanoparticles are placed in the central area of the corundum tube, then repeatedly filled with argon and evacuated by a mechanical pump for 3-5 times, and the temperature is raised to 850°C at a rate of 10°C per minute under an argon atmosphere. Stop argon filling, and pass 100 SCCM of N 2 / NH 3 (4% NH 3 ) mixed gas, and reacted at 850°C for 3 hours. A crystalline BN layer is covered on the surface of Fe-B nanoparticles, and the BN nanocapsule (see image 3 ).

[0046] The N source in the present embodiment also can be in solid state, and the N source of solid state is ammonium chloride (NH 4 Cl) or urea (CO(NH 2 ) 2 ) to get the same product.

Embodiment 2

[0047] Embodiment 2: with Ni 70 B 30 Nanoparticle catalysts prepared BN nanocapsules at 900 °C.

[0048] From 1mol / L KBH 4 With 0.1mol / L NiCl 2 Liquid phase reaction produces Ni with an average particle size of about 50 nanometers 70 B 30 nanoparticles. Use this as a catalyst and place it in the center of the corundum tube, then repeatedly fill it with argon and evacuate it with a mechanical pump for 3-5 times, and raise the temperature to 900°C at a rate of 10°C per minute under an argon atmosphere. Stop argon filling, and pass 100 SCCM of N 2 / NH 3 (4%NH 3 ) mixed gas at 900°C for 2 hours. A crystalline BN layer is covered on the surface of the catalyst particle to obtain a Ni-B-wrapped BN nanocapsule with a diameter of about 40-120nm. (See Figure 4 )

Embodiment 3

[0049] Embodiment 3: with Co 75 B 25 Nanoparticle catalysts prepared BN nanocapsules at 900 °C.

[0050] From 1mol / L KBH 4 With 0.1mol / L CoCl 2 Liquid-phase reaction produces Co with an average particle size of about 30 nm 75 B 25 nanoparticles. The obtained Co-B nanoparticles are placed in the central area of the corundum tube, then repeatedly filled with argon and evacuated by a mechanical pump for 3-5 times, and the temperature is raised to 900°C at a rate of 10°C per minute under an argon atmosphere. Stop argon filling, and pass 100 SCCM of N 2 / NH 3 / C 2 h 2 (4%NH 3 , 10% C 2 h 2 ) mixed gas at 900°C for 2 hours. A B-C-N layer is covered on the surface of the catalyst particles to obtain B-C-N nanocapsules with a diameter of about 30-100nm covering Ni-B. (See Figure 5 )

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com