Method for coating multiple compound high anti-reflection films on inner surface and outer surface of glass tube with length/aperture ratio greater than 30

An inner and outer surface, multi-layer composite technology, which is applied in the field of high anti-reflection film coating of heat-collecting glass tubes with a length of L4000×aperture D115mm, can solve problems such as no reports, and achieve long service life, simple equipment and mutual solubility. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

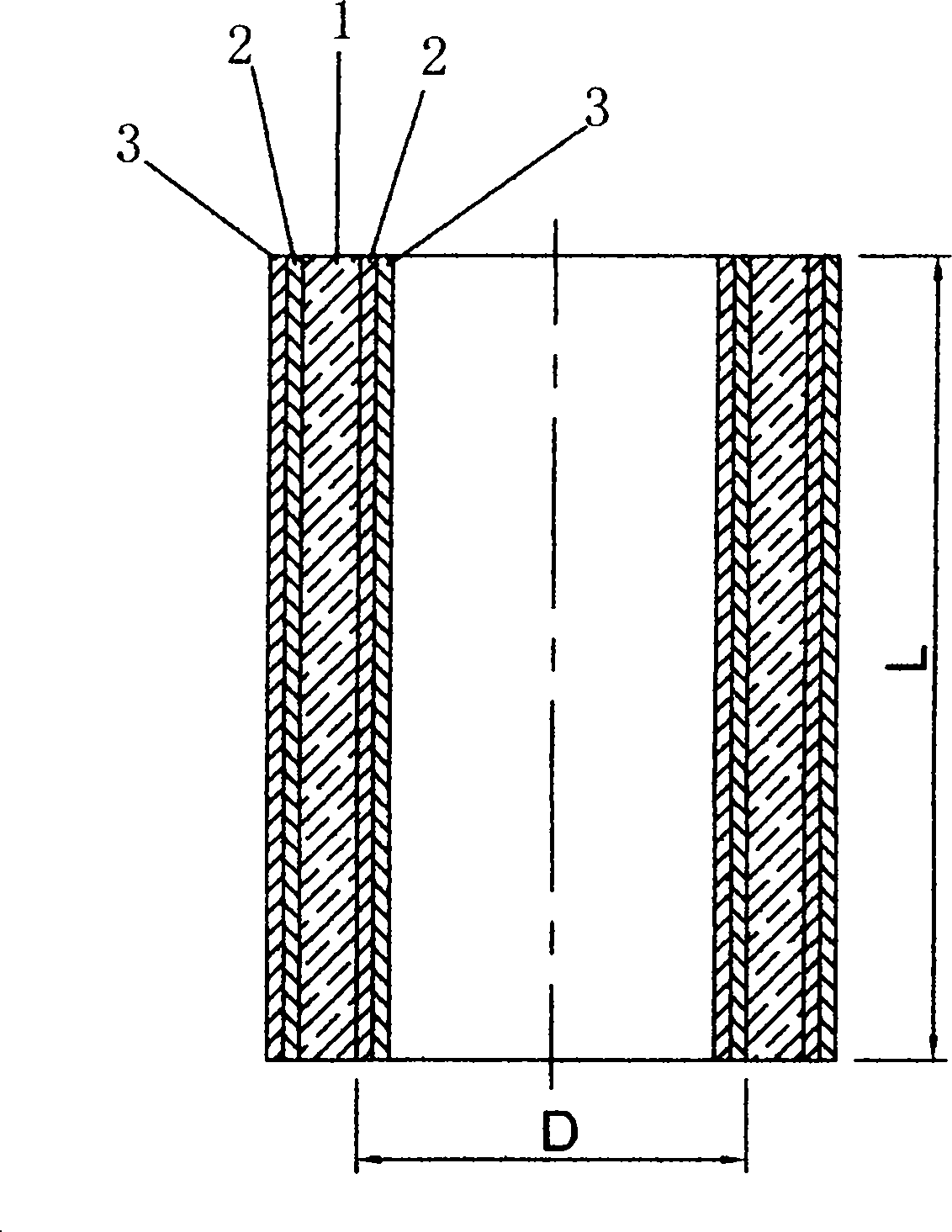

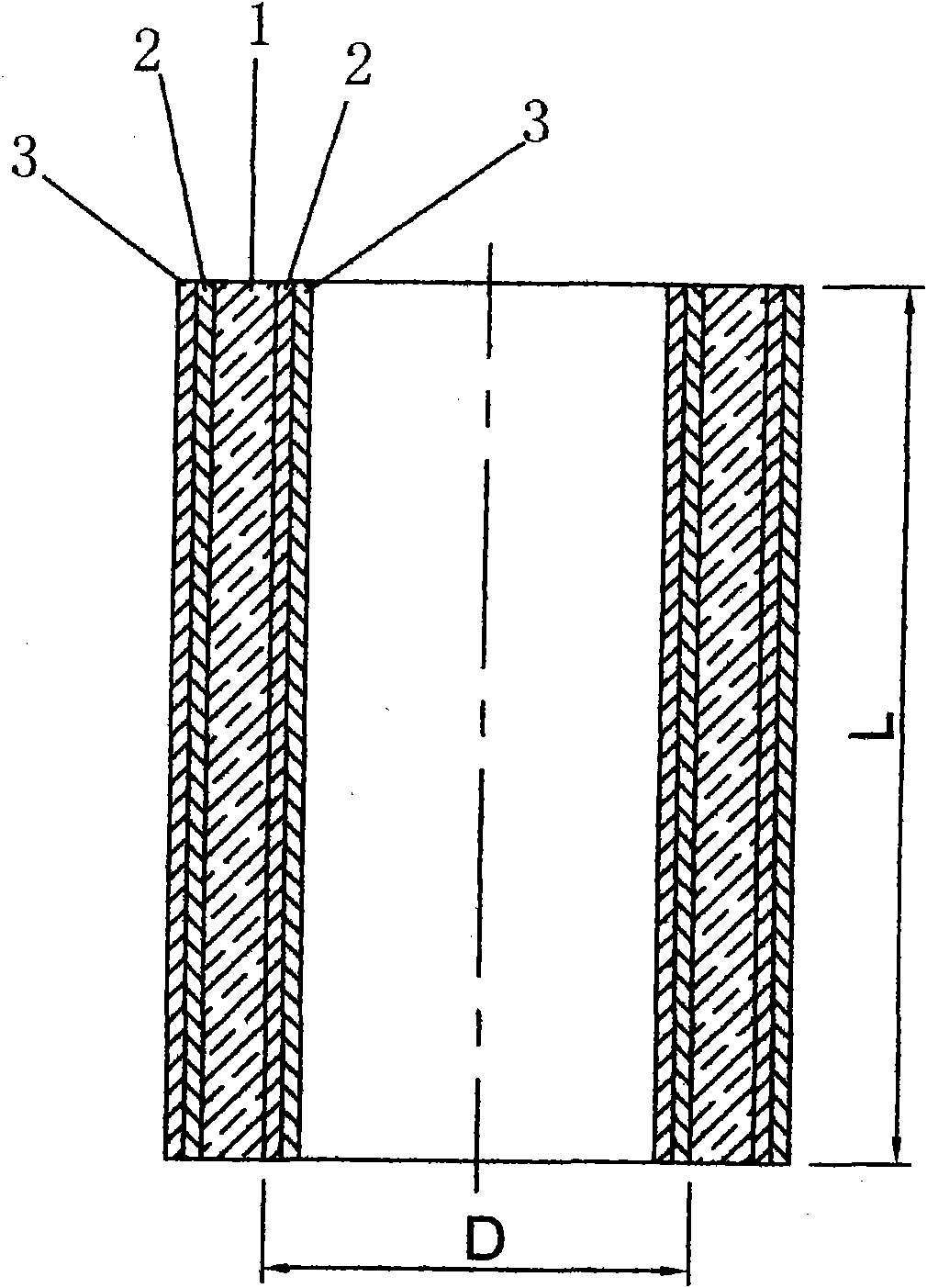

[0042] Embodiment 2, refer to the attached figure 1 .

[0043] A method for coating the inner and outer surfaces of a glass tube with a length / aperture ratio greater than 30 with a multi-layer composite high anti-reflection film, the high anti-reflection coated glass tube prepared by the method comprises a glass tube (1), and the glass tube (1 ) high anti-reflection layer TiO coated on the inner and outer surfaces 2 Thin film layer (2), and TiO inside and outside the tube 2 SiO coated on the surface of the thin film layer 2 Thin film layer (3); said TiO 2 Thin film layer (2) and SiO 2 Thin film layers (3) are arranged alternately; its film coating method is to include the preparation of TiO 2 Sol and preparation of SiO 2 Sol preparation including sol, thin film preparation and film post-treatment, and its

[0044] a, the TiO 2 The preparation of the sol is to adopt the step-by-step hydrolysis method, under the condition of magnetic stirring, add anhydrous ethanol, buty...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com