Preparation method of quartz sand/titanium dioxide composite catalyst

A composite catalyst, titanium dioxide technology, used in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of low pollutant degradation efficiency, easy to ignore the interaction between pollutants and catalysts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

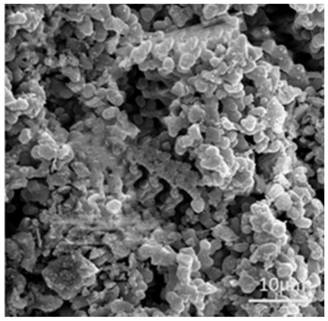

Image

Examples

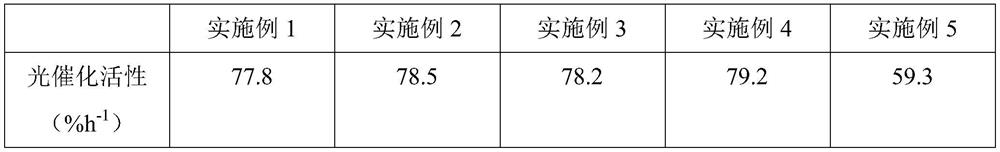

Embodiment 1

[0028] A preparation method of quartz sand / titanium dioxide composite catalyst, comprising the following steps,

[0029] Step 1: Pretreatment; Weigh 10mL of tetrabutyl titanate, add it dropwise into deionized water at a speed of 0.10ml / s-0.20ml / s, stir while dripping, and add nitric acid, tetrabutyl titanate, The addition of deionized water and nitric acid is mixed according to the mass ratio of 11%: 88%: 0.8%, to obtain a milky white suspension;

[0030] Step 2: water bath; stir the suspension in a water bath at 50°C for 1 hour to obtain a light blue titanium dioxide sol;

[0031] Step 3: mixing; taking the titanium dioxide sol and diluting it with water, adding quartz sand into the titanium dioxide sol, the mass ratio of the added quartz sand to titanium dioxide is 2.5%;

[0032] Step 4: drying; drying the mixture in an oven at 105°C to constant weight to obtain solid particles;

[0033] Step 5: hydrothermal treatment: put the solid particles in a hydrothermal reaction ket...

Embodiment 2

[0035] The preparation method of the quartz sand / titania composite catalyst of present embodiment 2 comprises the following steps,

[0036] Step 1: Pretreatment; Weigh 10mL of tetrabutyl titanate, add it dropwise into deionized water at a speed of 0.10ml / s-0.20ml / s, stir while dripping, and add nitric acid, tetrabutyl titanate, The addition of deionized water and nitric acid is mixed according to the mass ratio of 11%: 88%: 0.8%, to obtain a milky white suspension;

[0037] Step 2: water bath; stir the suspension in a water bath at 50°C for 1 hour to obtain a light blue titanium dioxide sol;

[0038] Step 3: mixing; taking the titanium dioxide sol and diluting it with water, adding quartz sand into the titanium dioxide sol, the mass ratio of the added quartz sand to titanium dioxide is 5.0%;

[0039] Step 4: drying; drying the mixture in an oven at 105°C to constant weight to obtain solid particles;

[0040] Step 5: hydrothermal treatment: put the solid particles in a hydrot...

Embodiment 3

[0042] The preparation method of the quartz sand / titania composite catalyst of present embodiment 3 comprises the following steps,

[0043]Step 1: Pretreatment; Weigh 10mL of tetrabutyl titanate, add it dropwise into deionized water at a speed of 0.10ml / s-0.20ml / s, stir while dripping, and add nitric acid, tetrabutyl titanate, The addition of deionized water and nitric acid is mixed according to the mass ratio of 11%: 88%: 0.8%, to obtain a milky white suspension;

[0044] Step 2: water bath; stir the suspension in a water bath at 50°C for 1 hour to obtain a light blue titanium dioxide sol;

[0045] Step 3: mixing; take the titanium dioxide sol and add water to dilute, add quartz sand to the titanium dioxide sol, and add the mass ratio of quartz sand to titanium dioxide to be 7.5%;

[0046] Step 4: drying; drying the mixture in an oven at 105°C to constant weight to obtain solid particles;

[0047] Step 5: hydrothermal treatment: put the solid particles in a hydrothermal rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com