Low carbon olefin oligomerization process control method

A low-carbon olefin and reaction process technology, applied in the field of low-carbon olefin oligomerization reaction process control, can solve problems such as drifting in the optimization zone, failure to maintain the best state of the catalyst, failure to detect and solve abnormal conditions in time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

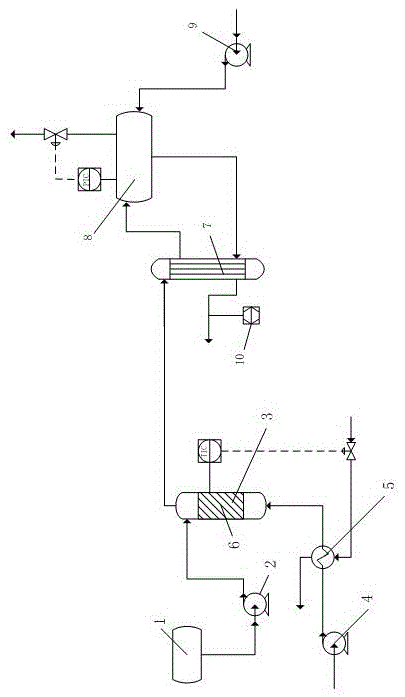

[0025] Such as figure 1 Shown, a kind of control method of low carbon olefin oligomerization process, comprises the following steps:

[0026] (1) The sodium dihydrogen phosphate aqueous solution with a content of 5% to 10% in the acid water tank 1 enters from the upper part of the neutralization settling tank 3 through the acid water pump 2 .

[0027] Wherein: the middle and upper part of the neutralization settling tank 3 is provided with a temperature controller, and a Boer porcelain ring 6 is provided inside it.

[0028] (2) The low-carbon olefins are transported to the heater 5 through the raw material pump 4, and at the same time, the low-pressure steam with a pressure of 0.1-0.3 MPa is input into the heater 5 to heat the low-carbon olefins, and the temperature is 30 ° C ~ 60 ° C and the alkali Low-carbon olefins with nitrogen content not greater than 1ppm and low-pressure steam condensate; low-pressure steam condensate is discharged from heater 5; low-carbon olefins wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com