Titanium dioxide/silicon dioxide photocatalyst and preparation method thereof

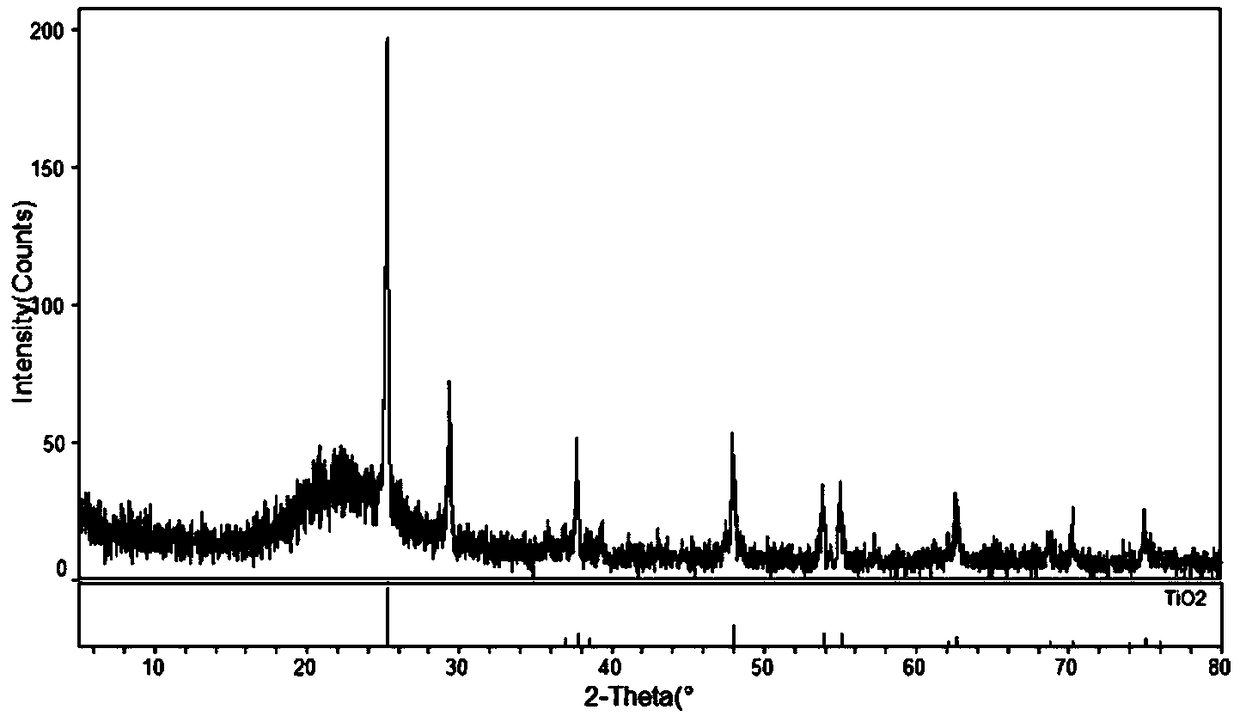

A technology of silicon dioxide and titanium dioxide, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as unfavorable photocatalytic activity and improvement, and achieve good photocatalytic activity and mild preparation conditions. , the effect of high purity of anatase phase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

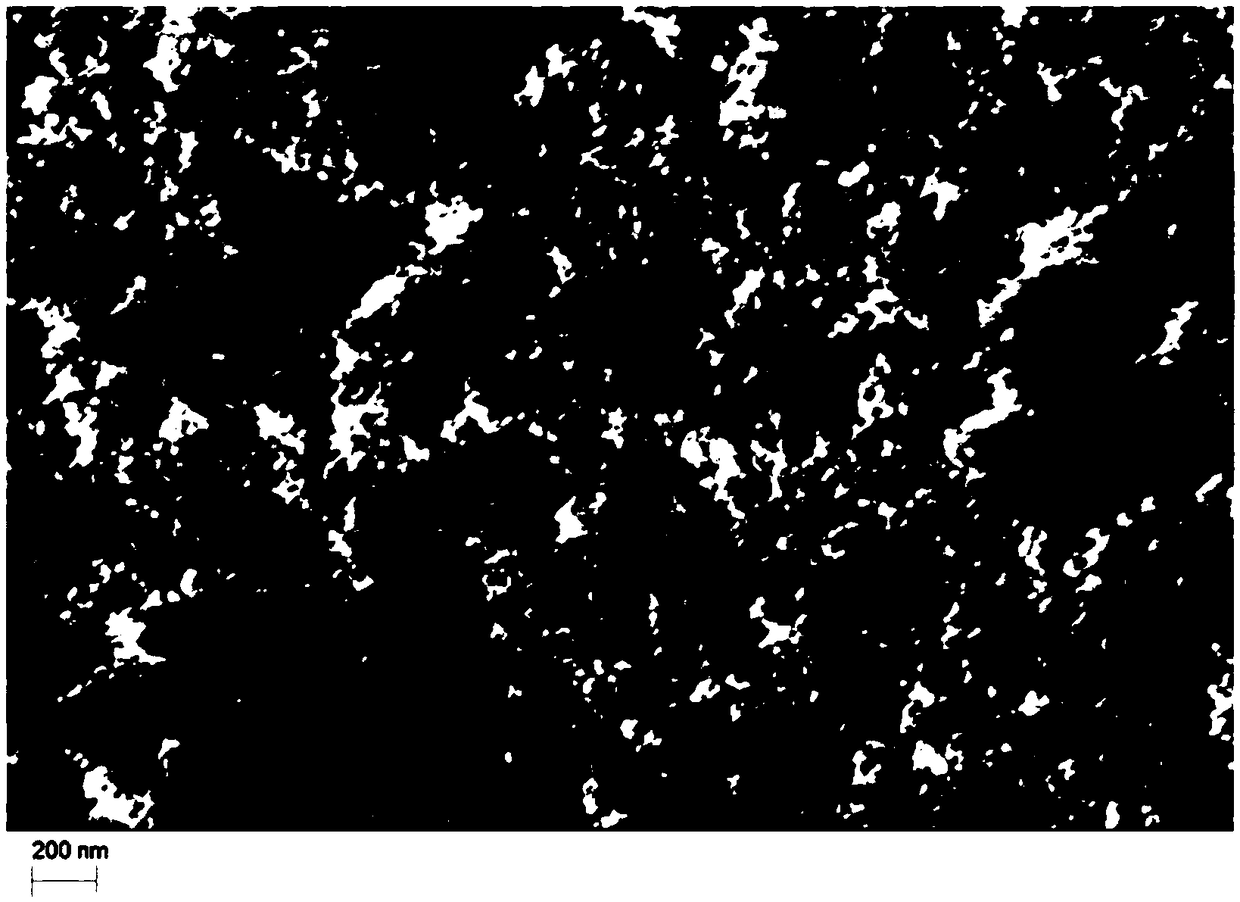

[0028] The preparation method of the titania / silica photocatalyst of an embodiment of the present invention, comprises the following steps:

[0029] (1) Take titanate and add it to the mixed solution of ethanol and glacial acetic acid, add water dropwise while stirring, after the dropwise addition is completed, stir and react at 40°C to 65°C to obtain a hydrolyzate;

[0030] (2) Dropping a strengthening oxidizing acid into the hydrolyzate, and continuing to stir and react at 60°C to 85°C after the dropwise addition, to obtain a titanium dioxide sol;

[0031] (3) Add titanium dioxide sol into silica gel, stir ultrasonically, and dry to obtain the product.

[0032] In the above preparation method, water is added dropwise to the system of titanate, ethanol and glacial acetic acid to control the hydrolysis rate of titanate to obtain amorphous titanium dioxide particles with smaller particle diameters. In one example, the volume ratio of glacial acetic acid, titanate, ethanol and ...

Embodiment 1

[0047] (1) Preparation of titania sol

[0048] Take a certain amount of absolute ethanol and add it to the flask, add a certain amount of glacial acetic acid, and stir for 20 minutes. A certain amount of tetrabutyl titanate was added to the above mixed solution, and after stirring for 20 minutes, a certain amount of deionized water was slowly added dropwise while stirring for 20 minutes to obtain a white turbid hydrolyzate. After the deionized water was added dropwise, the water bath was heated to 50° C. and stirred continuously for 20 min. Wherein, the volume ratio of glacial acetic acid, tetrabutyl titanate, absolute ethanol and deionized water is 1:10:100:200.

[0049] Take a certain amount of 0.2mol / L nitric acid solution, add it dropwise to the above hydrolyzed solution under stirring, and drop it in 5-10 minutes. The volume ratio of the nitric acid solution to the above reaction solution is 1:1.5. After the dropwise addition, a condenser was added to the flask, the tem...

Embodiment 2

[0062] (1) Preparation of titania sol

[0063] Take a certain amount of absolute ethanol and add it to the flask, add a certain amount of glacial acetic acid, and stir for 5 minutes. Add a certain amount of tetrabutyl titanate into the above mixed solution, stir for 30 minutes, and slowly add a certain amount of deionized water dropwise while stirring for 15 minutes to obtain a white turbid hydrolyzate. After the deionized water was added dropwise, the water bath was heated to 65° C. and stirred continuously for 10 min. Wherein, the volume ratio of glacial acetic acid, tetrabutyl titanate, absolute ethanol and deionized water is 1:8:80:150.

[0064] Take a certain amount of 0.2mol / L nitric acid solution, add it dropwise to the above hydrolyzed solution under stirring, and drop it in 10 minutes. The volume ratio of the nitric acid solution to the above reaction solution is 1:1.2. After the dropwise addition, a condenser was added to the flask, the temperature of the water bat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com