Preparation method and application of three-dimensional multistage flower-like cobalt-titanium spinel nano material

A nano-material and spinel technology, which is applied in the field of preparation of three-dimensional multi-level flower-shaped cobalt-titanium spinel nano-materials, can solve the problems of irregular shape and structure, accompanied by impurities, small specific surface area, etc., to achieve Well-developed pore structure, low cost, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

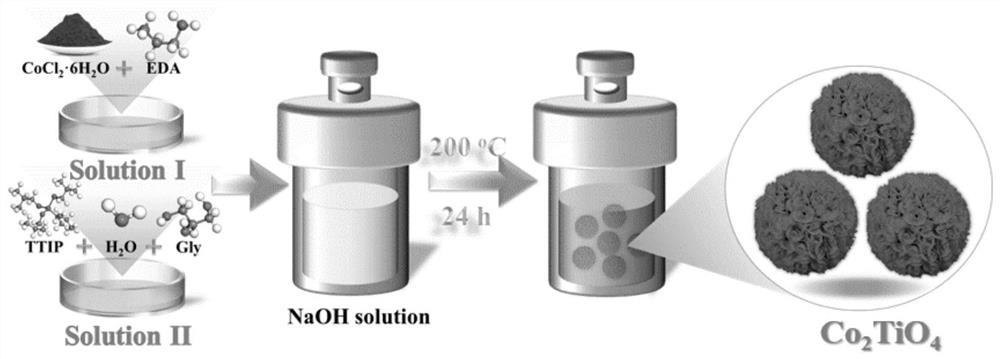

[0028] 1.25mmolCoCl·6H 2 O is dissolved in 8mL (15.625mol / L) ethylenediamine solution and makes cobalt-ethylenediamine precursor; 1.25mmol tetraisopropyl titanate is dissolved in the aqueous solution of glycerol (the use volume of glycerol is 32mL , the concentration of glycerol is 15.625mol / L, and the use volume of water is 20mL) to prepare the titanium-glycerol precursor; pour the above-mentioned cobalt-ethylenediamine precursor and titanium-glycerol precursor into 16mL In a NaOH solution with a concentration of 4mol / L, and encapsulated in a polytetrafluoroethylene reactor liner equipped with a stainless steel shell, react at 200°C for 24h, then centrifuge at 8000rpm for 3min, wash at 60°C After drying for 12 h, the three-dimensional hierarchical flower-like cobalt-titanium spinel nanomaterial Co 2 TiO 4 .

[0029] The process flow chart of above-mentioned preparation process sees figure 1 .

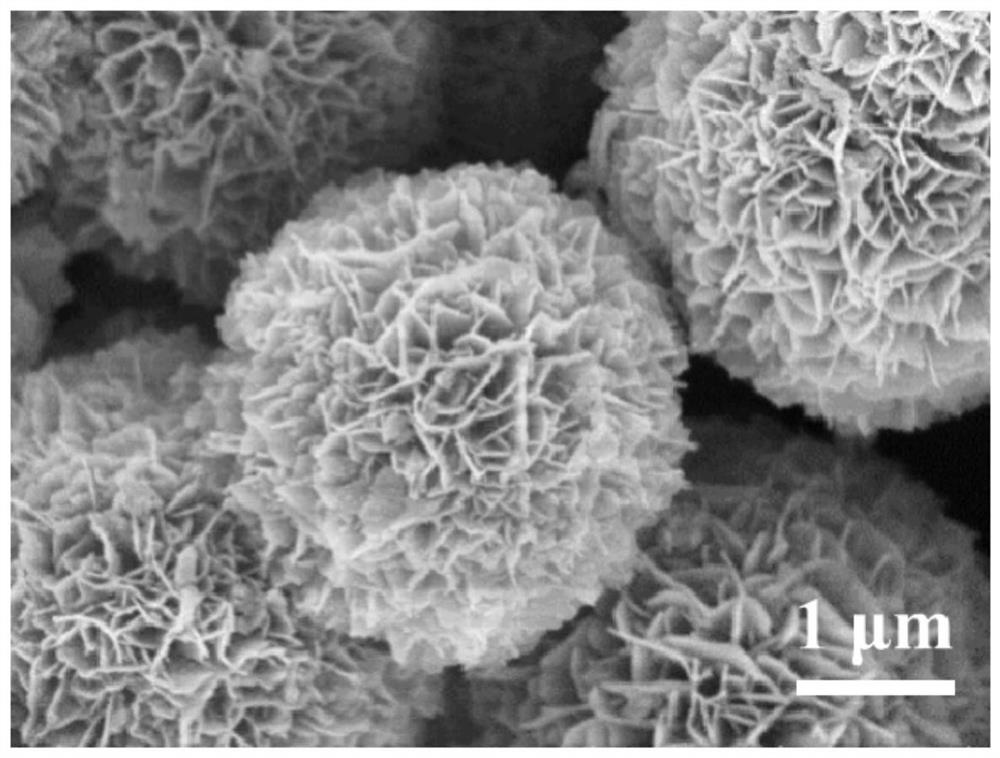

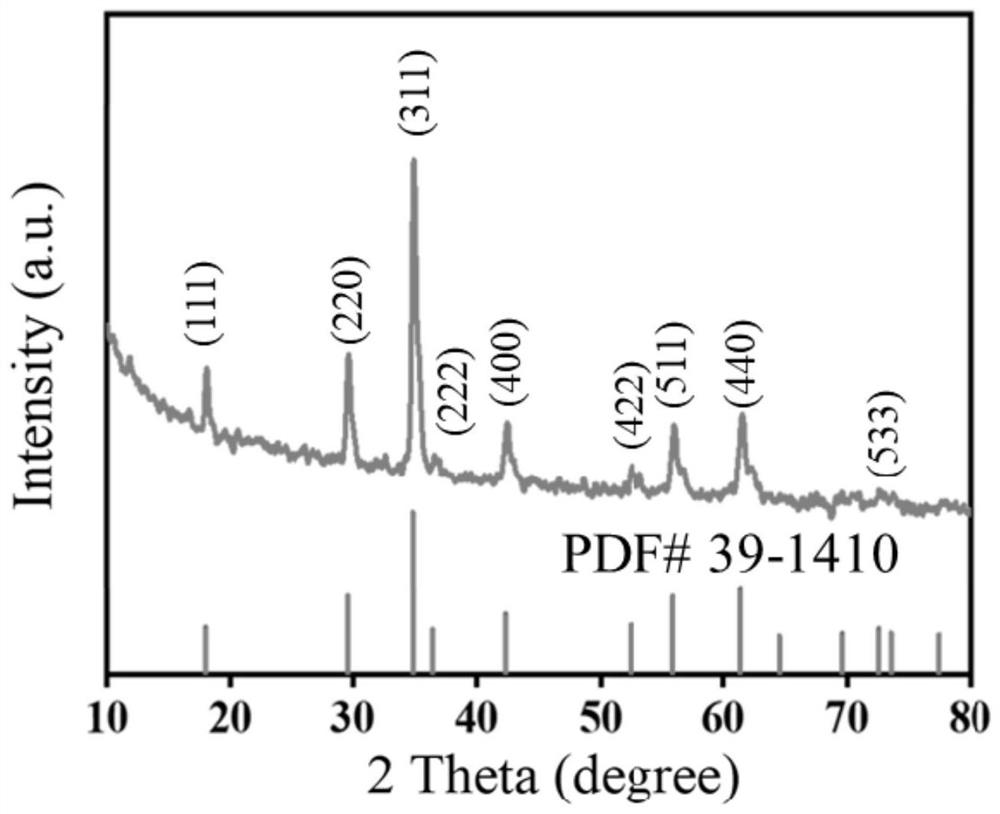

[0030] For the three-dimensional multi-level flower-like cobalt-titanium spin...

Embodiment 2

[0039] 1.25mmolCoC 2 o 4 4H 2 O is dissolved in 8mL (15.625mol / L) ethylenediamine solution and makes cobalt-ethylenediamine precursor; 1mmol tetraisopropyl titanate is dissolved in the aqueous solution of glycerol (the use volume of glycerol is 25.6mL , the concentration of glycerol is 15.625mol / L, and the use volume of water is 20mL) to prepare the titanium-glycerol precursor; pour the above-mentioned cobalt-ethylenediamine precursor and titanium-glycerol precursor into 20mL In a NaOH solution with a concentration of 4mol / L, and encapsulated in a polytetrafluoroethylene reactor liner equipped with a stainless steel shell, react at 185°C for 24h, then centrifuge at 4000rpm for 3min, wash at 60°C After drying for 12 h, the three-dimensional hierarchical flower-like cobalt-titanium spinel nanomaterial Co 2 TiO 4 .

Embodiment 3

[0041] 1.25mmolCo(NO 3 ) 2 ·6H 2 O was dissolved in 8mL (15.625mol / L) ethylenediamine solution to prepare cobalt-ethylenediamine precursor; 2mmol tetrabutyl titanate was dissolved in glycerol aqueous solution (the use volume of glycerol was 51.2mL, The concentration of glycerol is 15.625mol / L, and the use volume of water is 40mL) to make titanium-glycerol precursor; Pour the above-mentioned cobalt-ethylenediamine precursor and titanium-glycerol precursor 4mol / L NaOH solution, and encapsulated in a polytetrafluoroethylene reactor liner equipped with a stainless steel shell, reacted at 210°C for 24h, then centrifuged at 6000rpm for 3min, washed, and at 60°C After drying for 12 h, the three-dimensional hierarchical flower-like cobalt-titanium spinel nanomaterial Co 2 TiO 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com