Antifouling coating composition, antifouling coating film formed from the composition, coated object having the coating film on surface, and method of antifouling by forming the coating film

一种防污涂料、组合物的技术,应用在防污/水下涂料、薄料处理、松香涂料等方向,能够解决难以设计涂膜厚度、涂膜可溶性增加、涂膜呈脆性等问题,达到容易涂膜设计、粘附性高、温度依赖性低的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0132]

[0133] The antifouling coating composition of the present invention can be prepared by mixing the copolymer (A), the copper salt (B) and, if necessary, known additives such as the cuprous oxide and the plasticizer in a solvent. to prepare.

[0134] Properly adjust the usage amount of the copolymer (A), the copper salt (B) and the like so that each satisfies the requirement of the triorganosilyl ester-containing copolymer (A) in the antifouling coating composition. , the content of the copper salt (B) and the like.

[0135] Usable solvents include, for example, xylene, toluene, mineral spirits, MIBK, butyl acetate, and the like. Among them, xylene is particularly preferred. These solvents may be used alone or in combination of two or more.

[0136] When mixing, various materials such as the above-mentioned copolymer (A) may be dissolved or dispersed in a solvent in advance. or preferably performed. For example, the above-mentioned copolymer (A) and the above-men...

Embodiment

[0159] The features of the present invention are clearly described below with reference to Examples. However, the invention is not limited to the examples.

[0160] "%" in each of the following production examples, comparative production examples, examples, and comparative examples represents "% by weight". The viscosity is a value measured at 25°C, and is a value measured with a Brookfield rotational viscometer (B-type viscometer). The weight average molecular weight (Mw) is a value obtained by GPC (polystyrene conversion value). The conditions for GPC are as follows:

[0161] Device---HLC-8220GPC manufactured by Tosoh Corporation

[0162] Column---TSKgel SuperHZM-M 2pcs

[0163] Flow---0.35mL / min

[0164] Detector---RI

[0165] Column thermostat temperature---40℃

[0166] Eluent---THF

[0167] The non-volatile content is a value obtained by heating at 110° C. for 3 hours.

[0168] The unit of the compounding quantity of each component shown in Table 1 is "g".

manufacture example 1

[0169] Production example 1 (preparation of copolymer solution (A), S-1)

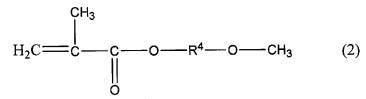

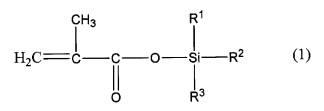

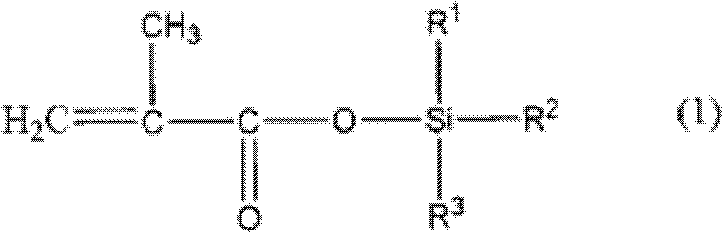

[0170] Put 230g of xylene into a 1000ml flask equipped with a thermometer, a reflux cooler, a stirrer and a dropping funnel, then stir at 100±2°C in nitrogen, while adding 230g of triisopropylsilyl methacrylate A mixture of ester, 210g methoxyethyl methacrylate, 30g methyl methacrylate, 30g ethyl acrylate and 4g (initial addition) tert-butyl peroxy-2-ethyl hexanoate was dropped over 1 hour into the flask. After dropping, polymerization reaction was performed at 100±2° C. for 2 hours. Afterwards, stir at 100±2°C, and add 1 g of tert-butylperoxy-2-ethyl hexanoate every 2 hours, add three times in total, add 270 g of xylene after the polymerization reaction and dissolve it, Thus, a triorganosilyl ester-containing copolymer solution S-1 was prepared. Table 1 shows the viscosity, non-volatile matter content, Mw and Tg of S-1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com