Heat exchanger on which anti-fouling film coating is formed

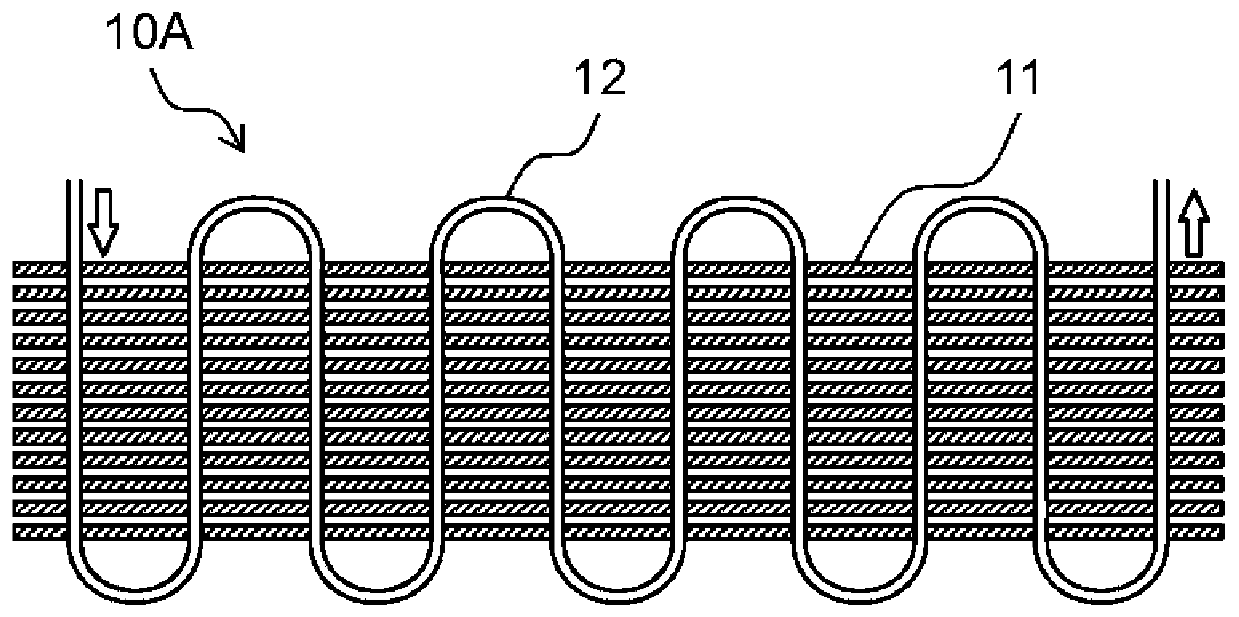

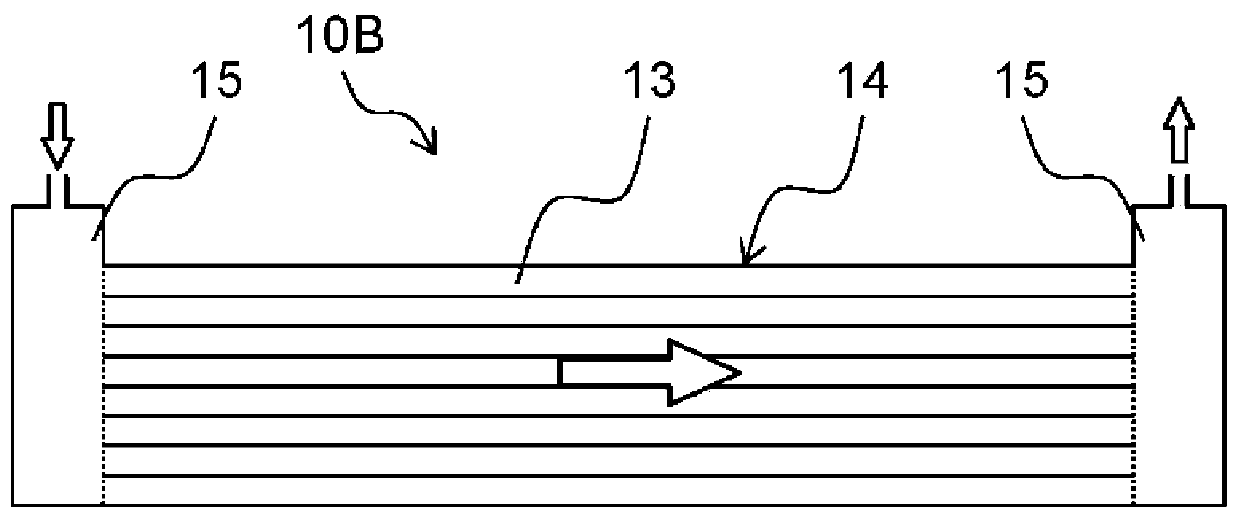

A technology of heat exchanger and covering film, which is applied in heat exchange equipment, heat transfer modification, lighting and heating equipment, etc. It can solve the problems of heat exchanger performance degradation and sanitation problems, and achieve the effect of preventing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

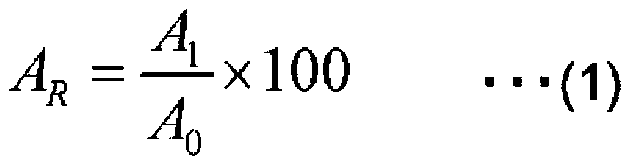

[0083] An aluminum metal plate is prepared as a part of the heat exchanger as a fragmented part. Prepare a coating solution obtained by sufficiently dispersing silica particles with an average particle diameter of 20 nm in ethanol as a dispersant by adjusting pH by a known method, apply the coating solution on about half of the surface of an aluminum metal plate, and By drying, the sample for evaluation in which the antifouling film of Example 1 was formed was produced. In this sample for evaluation, an antifouling film was formed on half of the surface, and an antifouling film was not formed on the remaining half. In this sample for evaluation, the surface of the formed antifouling film had irregularities with an arithmetic mean roughness Ra of 10 nm. In addition, the dust adhesion rate of the sample for evaluation was "⊚".

Embodiment 2

[0085] As the silica particles, particles having an average particle diameter of 100 nm were used, and in the same manner as in Example 1, an evaluation sample in which an antifouling coating film was formed in Example 2 was produced. In this sample for evaluation, the surface of the formed antifouling film had irregularities with an arithmetic mean roughness Ra of 40 nm. In addition, the dust adhesion rate of the sample for evaluation was "◯".

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average roughness | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com