High-nitrogen-concentration composite microbial fertilizer and preparation method thereof

A technology of complex microorganisms and high nitrogen content, applied in fertilizer mixtures, fertilization devices, applications, etc., can solve the problems of complex preparation process and difficulty in ensuring the number and activity of bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

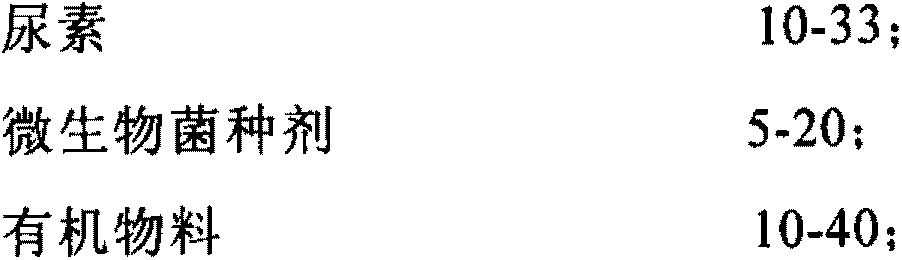

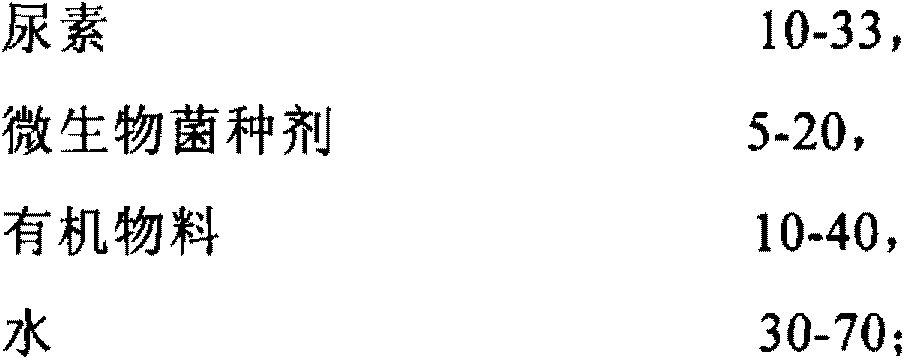

[0031] A preparation method of high nitrogen-containing compound microbial fertilizer, the method comprises the following steps:

[0032](1) Add 39.12kg of urea, 18kg of microbial inoculum agent, 12kg of organic material and 50.88kg of water into the fermentation vessel and stir evenly before fermenting. Wherein, the microbial strain agent is Bacillus subtilis (Bacillus subtilis), and its effective number of viable bacteria is greater than or equal to 3 billion / ml. The preparation of the strain can be done by conventional operations in the field. The organic material contains 10wt% of fish meal and 25wt% of soybean meal %, corn flour 30wt%, peat 35wt%;

[0033] (2) On the 17th day of fermentation, it is found that a large amount of gas is produced in the container, and the weight percentage concentration of ammonium nitrogen in the detection material is less than 2%, that is, the fermentation is considered to be completed. Potassium dihydrogen phosphate is added to the fermen...

Embodiment 2

[0038] A preparation method of high nitrogen-containing compound microbial fertilizer, the method comprises the following steps:

[0039] (1) Add 48.9kg of urea, 7.5kg of microbial strain agent, 45kg of organic material and 48.6kg of water into the fermentation container, stir evenly and then ferment. Among them, the microbial strain agent is Bacillus subtilis, the effective number of viable bacteria is greater than or equal to 3 billion / ml, and the preparation of the strain can be performed by conventional operations in the field. Organic materials include fish meal 10wt%, soybean meal 25wt%, corn meal 30wt%, peat 35wt%;

[0040] (2) On the 21st day of fermentation, it is found that a large amount of gas is produced in the container, and the weight percentage concentration of ammonium nitrogen in the detection material is less than 2%, that is, the fermentation is considered to be completed. Add an appropriate amount of potassium dihydrogen phosphate to the fermented materia...

Embodiment 3

[0048] The preparation method of the high-nitrogen compound microbial fertilizer uses the microbial biochemical reaction method to convert and fix the fast-acting small-molecule amide nitrogen in urea into slow-acting macromolecular organic nitrogen, which specifically includes the following steps:

[0049] (1) material preparation: prepare materials according to the following components and contents: urea 20wt%, microbial strain agent 5wt%, organic material 40wt%, surplus is water, wherein, microbial strain agent is Bacillus subtilis (Bacillus subtilis), The number of effective viable bacteria is greater than or equal to 3 billion / ml, and the preparation of the bacteria can be done by conventional operations in the field. The organic material contains 10wt% of fish meal, 25wt% of soybean meal, 30wt% of corn meal, and 35wt% of peat;

[0050] (2) Add the above materials into the fermentation container and stir evenly. On the 23rd day of fermentation, a large amount of gas is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com