HMS@NiPt@Beta core-shell structure catalytic material and preparation method and application thereof

A technology of catalytic material and core-shell structure, applied in catalyst activation/preparation, chemical instruments and methods, molecular sieve catalysts, etc., can solve the problems of reduced catalyst stability, lack of metal regulation, loss of metal active components, etc. properties, enriching active sites, and improving catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

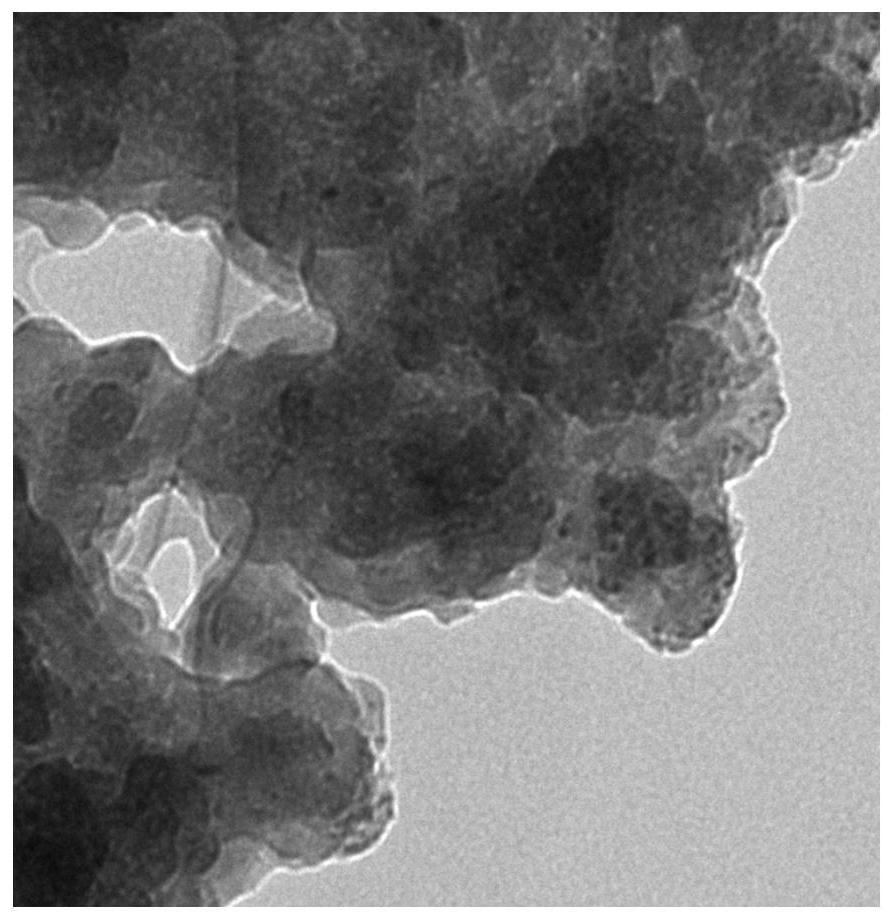

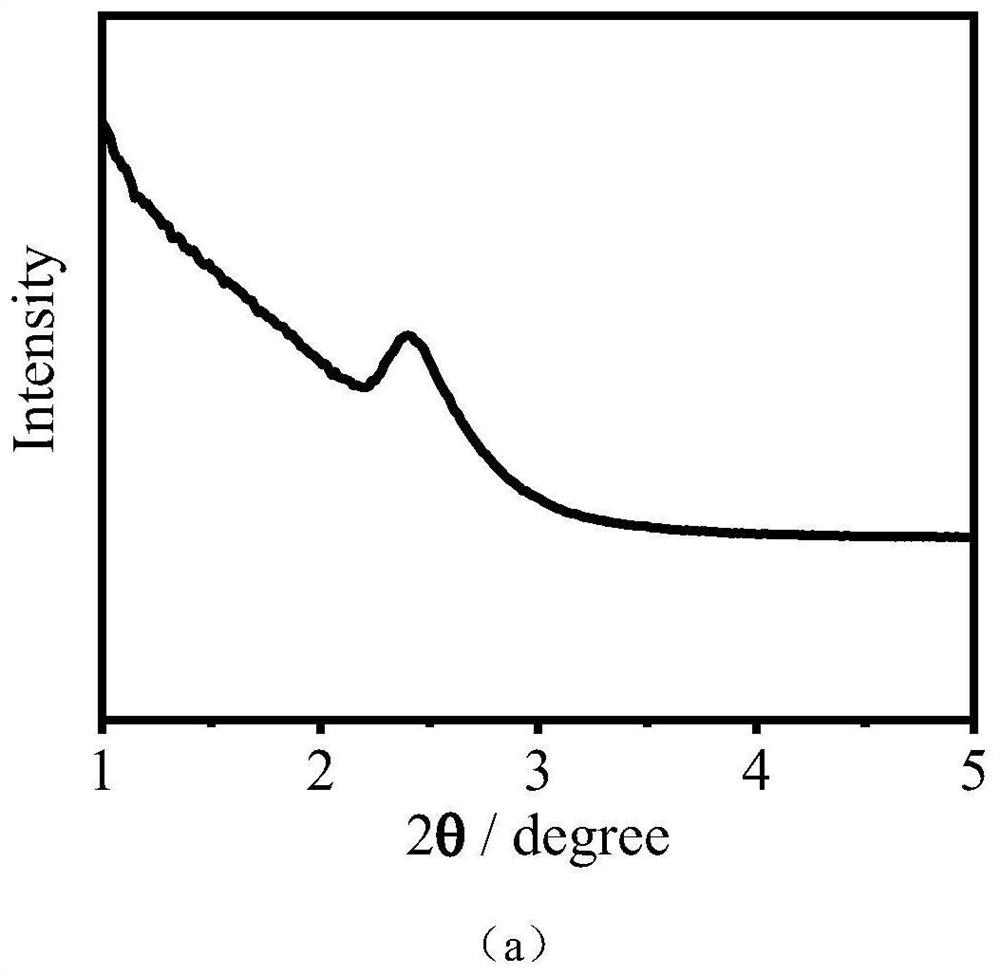

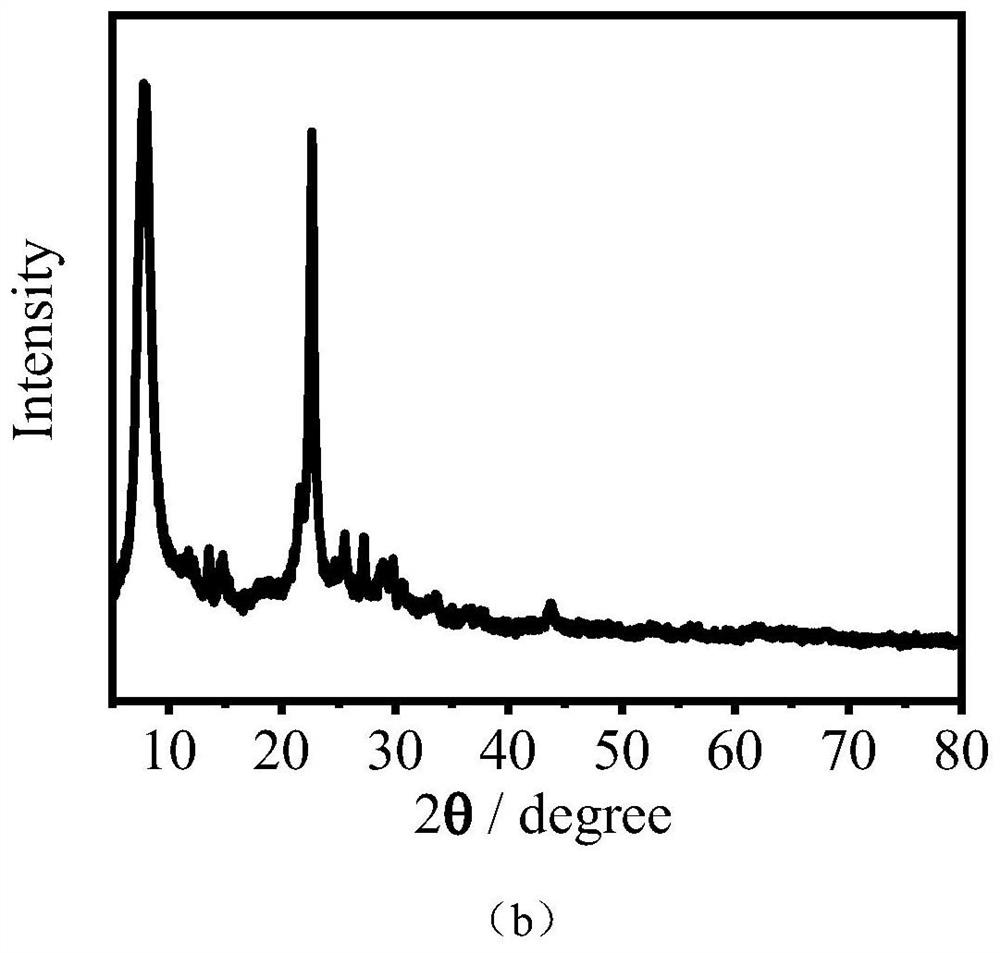

Image

Examples

preparation example Construction

[0035] The preparation method of HMS@NiPt@Beta core-shell structure catalytic material comprises the following steps:

[0036] Step 1) At room temperature, add silicon source, aluminum source, structure directing agent, NaOH, and deionized water into the reaction kettle, react at 120-160°C for 2-5 days, and filter after cooling down to room temperature; wash and filter with deionized water The cake is dried until the washing liquid is neutral, then roasted in an air flow of 5-50 mL / min at 400-700°C for 3-10 hours, and then lowered to room temperature to obtain a microporous Beta molecular sieve;

[0037] Step 2) At room temperature, add Ni source, Pt source, and deionized water into the reaction kettle, after stirring for 0.2-0.5h, add the microporous Beta molecular sieve prepared in step 1), continue stirring for 12-24h, and then Dry at 80-120°C for 12-24 hours, fully grind and put it into an oxygen plasma apparatus for treatment, each time for 2-10 minutes, and for 3-5 times...

Embodiment 1

[0045] At 25°C, add 5g of white carbon black, 0.79g of sodium metaaluminate, 12g of tetraethylammonium hydroxide, 0.8g of NaOH, and 25mL of deionized water into the reaction kettle, react at 140°C for 2 days, cool down to room temperature, and filter; Wash the filter cake with deionized water until the washing liquid is neutral and dry, then roast in 10mL / min air flow at 550°C for 4h, and lower to room temperature to obtain microporous Beta molecular sieves;

[0046] At 25°C, add 5g of hexaamine nickel chloride, 0.25g of tetraaminoplatinum tetrachloride, and 20mL of deionized water into the reaction kettle. After stirring for 0.5h, add 2g of microporous Beta molecular sieves and continue stirring for 24h. , dried at 120°C for 12h, fully ground and placed in an oxygen plasma instrument, using a radio frequency power of 200W, at 50mL / min of 10% (v / v) O 2 / Ar mixed gas flow treatment, each treatment 4min, treatment 3 times, the NiPt@Beta material was obtained;

[0047] At 25°C, ...

Embodiment 2

[0054] At 25°C, add 5g of fumed silica, 0.4g of aluminum isopropoxide, 12g of tetraethylammonium hydroxide, 0.5g of NaOH, and 15mL of deionized water into the reaction kettle, react at 150°C for 5 days, cool down to room temperature and filter ; Wash the filter cake with deionized water until the washing solution is neutral and dry, then roast at 600° C. for 3 hours in an air flow of 20 mL / min, and lower to room temperature to obtain a microporous Beta molecular sieve;

[0055] At 25°C, add 1.2g of nickel sulfamate, 0.4g of diammine platinum, and 30mL of deionized water into the reaction kettle. After stirring for 0.5h, add 3g of microporous Beta molecular sieves and continue stirring for 16h. Dry at ℃ for 15 hours, put it into an oxygen plasma instrument after fully grinding, select a radio frequency power of 300W, and use 8% (v / v) O at 60mL / min 2 / Ar mixed gas flow treatment, each treatment 3min, treatment 4 times, the NiPt@Beta material was obtained;

[0056] At 25°C, add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com