Cleaning composition for removing etching residues

A cleaning solution and residue technology, which is applied in the preparation of detergent mixture compositions, detergent compositions, detergent compounding agents, etc., can solve the problem of reduced reliability of semiconductor equipment, damage to silicon oxide layers, and etching rates of silicon oxide layers. higher question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

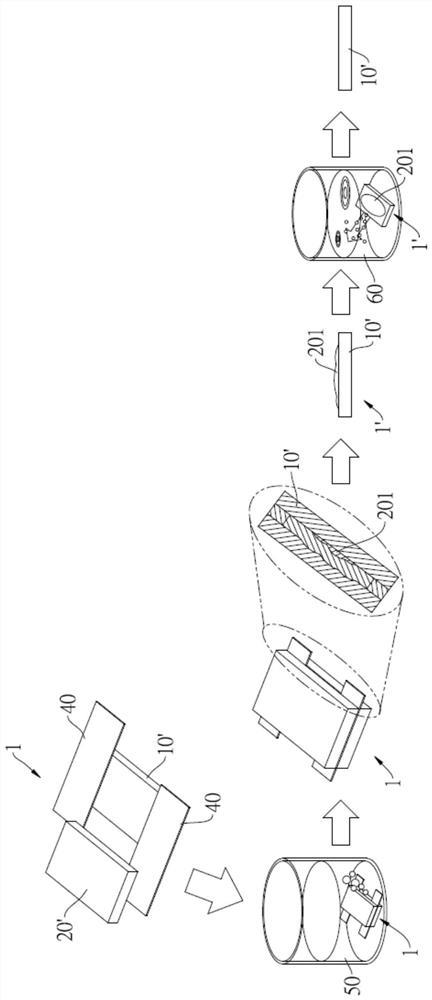

[0082] see figure 2 As shown, the prepared one thickness is The silicon nitride layer 20' and a thickness of An oxide-coated silicon wafer (thermal oxide wafer) fragment 10'. The oxide-coated silicon wafer fragment 10' comprises a silicon layer and a silicon oxide layer on the silicon layer. The silicon nitride layer 20' and the oxide-coated silicon wafer fragment 10' have the same shape and size. Attach two pieces of sealing tape 40 to two opposite edges of the oxide-coated silicon wafer fragment 10' respectively, and then cover and attach the silicon nitride layer 20' to the oxide-coated silicon wafer fragment 10' , thus forming a double-layer structure 1 . Therefore, there is a gap between the silicon nitride layer 20' and the oxide-coated silicon wafer fragment 10', and the distance of the gap is the thickness of the sealing tape 40, which is 80 micrometers (μm).

[0083] First, the double-layer structure 1 is soaked in an etching solution 50 at a temperature of 15...

Embodiment 1 to 15

[0085] Examples 1 to 15: Cleaning solution

Embodiment 1

[0086] The specific components contained in each of the cleaning solutions of Examples 1 to 15 and their concentrations are listed in Table 1. Taking Example 1 as an example, based on the total weight of the cleaning solution, 0.875wt% of HFSA as a fluorine-containing compound was mixed with 99.125wt% of water to obtain the cleaning solution of Example 1. Taking Example 3 again as an example, based on the total weight of the cleaning solution, 1.75wt% of HFSA as a fluorine-containing compound, 0.0084wt% of HF as an additive and 98.2416wt% of water were mixed to obtain Example 3 cleaning solution.

[0087] Table 1: The composition of the cleaning solution of embodiments 1 to 15 (E1 to E15) and its concentration, and the pH value of each cleaning solution

[0088]

[0089]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com