Treatment method of grinding waste liquid and hydrofluoric acid-containing waste liquid

A treatment method, hydrofluoric acid technology, applied in the preparation/treatment of fluosilicic acid, rare earth metal compounds, aluminum fluoride, etc., can solve problems such as environmental impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Reference will now be made in detail to the exemplary embodiments of the present invention, examples of which are illustrated in the accompanying drawings. Wherever possible, the same reference numbers are used in the drawings and descriptions to refer to the same or like parts.

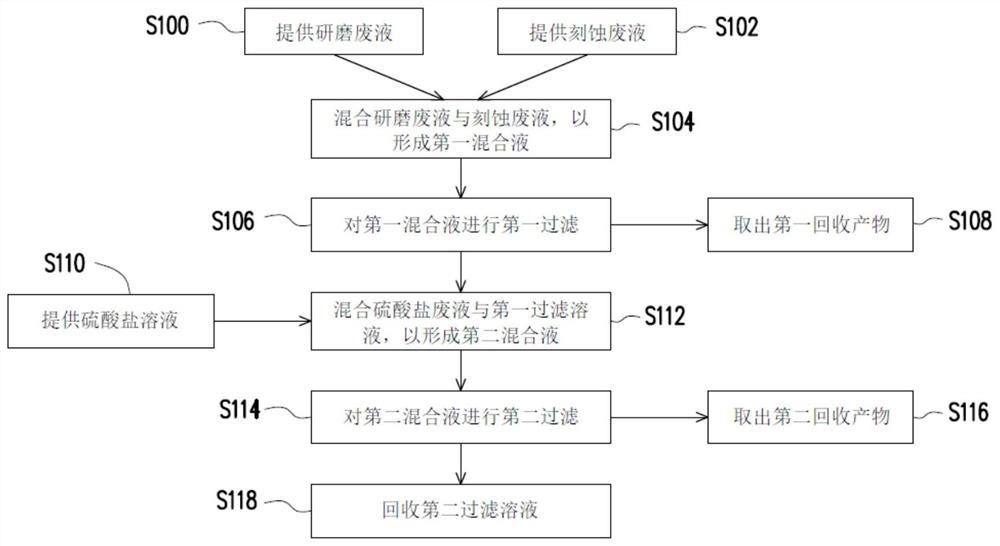

[0018] figure 1 It is a flowchart of a method for treating grinding waste liquid and hydrofluoric acid containing waste liquid according to some embodiments of the present invention. In some embodiments, the above method includes the following steps.

[0019] Please refer to figure 1 , performing step S100 to provide grinding waste liquid. The polishing waste comes from the used polishing liquid during the chemical mechanical polishing process. For example, the CMP process can be used to planarize oxides (such as silicon oxide), nitrides (such as silicon nitride), metals (such as tungsten, copper), or combinations thereof on a semiconductor wafer. However, the above-mentioned chemical mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com