Method for recovering fluorine resource from fluorination residues of feed phosphate

A technology for feed phosphate and defluorination residues, applied in calcium/strontium/barium sulfate, fluorosilicic acid, halogenated silicon compounds, etc., can solve problems such as resource utilization, reduce processing costs, increase economic benefits, and save mining Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] This embodiment adopts the method of continuous circulation treatment, and the percentages in this embodiment, unless otherwise specified, all refer to mass percentages.

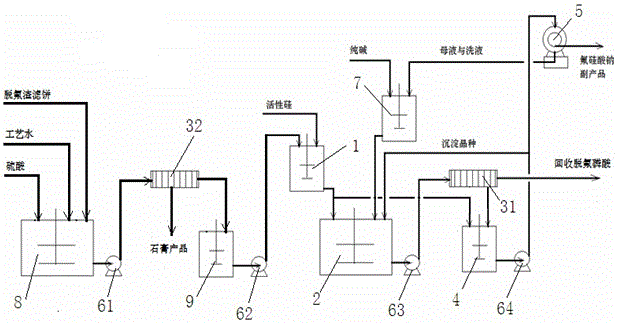

[0036] see figure 1 , the defluorinated slag (see Table 1 for components) produced by 5000kg / h feed phosphate production, 1825kg / h98%H 2 SO 4 and 3500kg / h process water (including the gypsum washing water of the subsequent process), continuously added to the decomposition and sedimentation tank 8, maintaining the temperature of the reaction tank at 40-60 ° C, and the residence time of the material is 45-60min; for the complete material of reaction precipitation, use the first Pump 61 is sent into the second filter press 32 to filter, and 3000kg / h process water carries out countercurrent washing; Obtain 6765kg / h containing 15.24%P respectively 2 o 5 The mixed filtrate of phosphoric acid and fluosilicic acid with 9.79% F is sent to the storage tank 9 for standby; the washing liquid 3500kg / h is return...

Embodiment 2

[0044] As shown in the figure, the defluorinated slag wet filter cake (see Table 2 for components) in the production of 7000kg / h feed calcium hydrogen phosphate, 1825kg / h98%H 2 SO 4 and 1200kg / h process water (including the gypsum washing water of the subsequent process), continuously add in the decomposition and sedimentation tank 8, maintain the temperature of the reaction tank at 40-60 ° C, and the residence time of the material is 45-60min; for the complete material of the reaction precipitation, use the first Pump 61 is sent into the second filter press 32 to filter, and 1000kg / h process water carries out countercurrent washing; Obtain 6265kg / h containing 16.46%P respectively 2 o 5 The mixed filtrate of phosphoric acid and fluosilicic acid with 10.57% F is sent to the storage tank 9 for standby; the washing liquid 1200kg / h is returned to the decomposition and sedimentation tank 8 as process water; the gypsum filter cake 3560kg / h containing 10% of free water is used as a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com