Preparation method of high transparent magnesium silicate and derivative thereof

A technology of magnesium silicate and derivatives, applied in magnesium silicate, aluminum silicate, silicate and other directions, can solve the problems of long reaction period, instability, huge investment amount, etc., to achieve stable product quality and reduce cost input , to avoid the effect of excessive accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

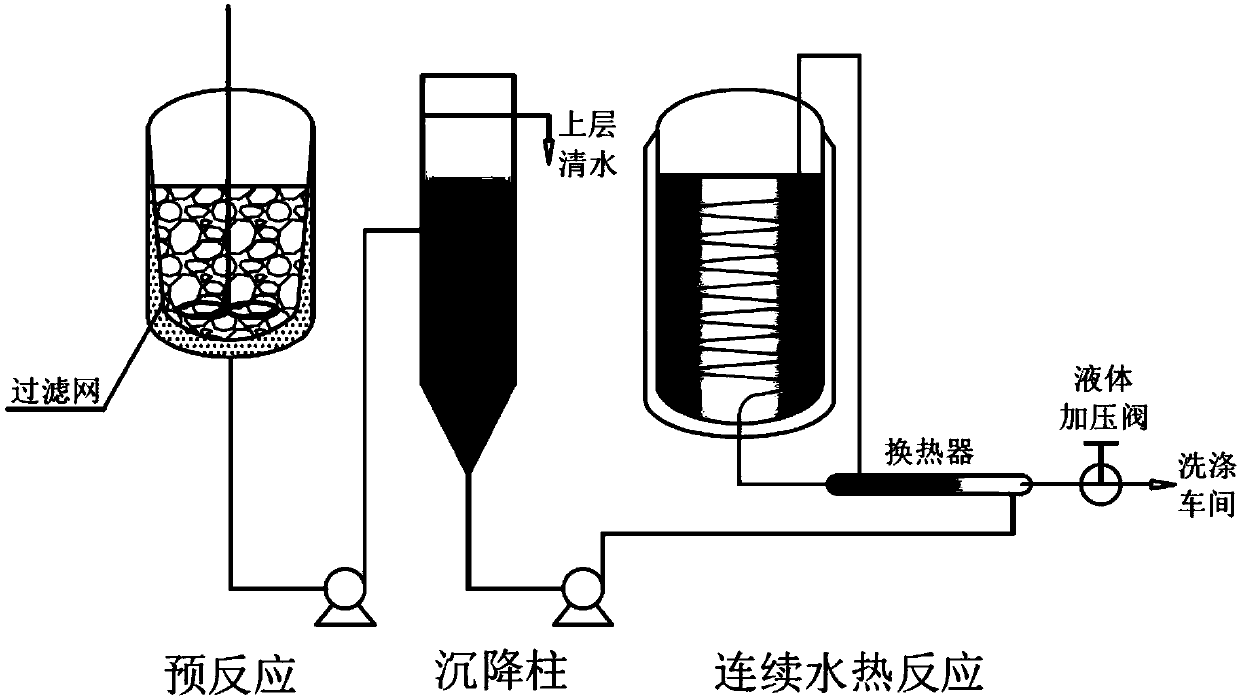

[0031] Such as figure 1 Shown, the embodiment of the present invention a kind of preparation method of highly transparent magnesium silicate and its derivatives, comprises the following steps,

[0032] Step S1: uniformly mixing the silicon-containing compound solution, the magnesium-containing compound solution, the modified compound solution and the pH regulator to form a reaction precursor;

[0033] Step S2: placing the reaction precursor in a constant temperature stirring tank at 0-95°C, and pre-reacting for 0-36 hours; the pre-reaction process here is the process of realizing colloidal aging;

[0034] Step S3: Put the reaction precursor into the settling column, after the solid content in the reaction precursor is 5-10%, adjust the liquid pressure valve to 0.5-18Mpa, and pump it into the The heat exchanger flows through a constant temperature heating zone at 150-350° C., flows out after passing through the heat exchanger again, and washes and dries the reactants flowing o...

specific Embodiment 1

[0052] Step S1: under stirring, add 50L 0.8mol / L sodium silicate solution to 50L 0.54mol / L magnesium sulfate solution to form a colloidal mixture; add a pH regulator solution to the mixture, and control the reaction pH value to 10; get A reaction precursor with a solid content of 2%;

[0053] Step S2: Put the reaction precursor in a constant temperature stirring tank at 25°C, and pre-react for 15 hours;

[0054] Step S3: Put the reaction precursor into the settling column. After the solid content in the reaction precursor is 9%, adjust the liquid pressure valve to 2.5MPa, and pump it into the heat exchanger with a pressure pump, and flow through 200 After the constant temperature heating zone at ℃, it passes through the heat exchanger again, and flows out after reaching the liquid pressure valve, and then after washing and drying, the magnesium silicate product is obtained, such as figure 2 shown.

[0055] Grind the product into powder, add it into deionized water under sti...

specific Embodiment 2

[0056] Step S1: under stirring, add 25L 0.05mol / L lithium carbonate solution and 25L 0.02mol / L HF solution to 25L 0.056mol / L magnesium sulfate solution to form mixture I; add 50L 0.04mol / L silica sol solution to In the mixture I, a colloidal mixture II is formed, a pH regulator solution is added to the mixture II, and the reaction pH is controlled to be 8; a reaction precursor with a solid content of 0.1% is obtained;

[0057] Step S2: Put the reaction precursor in a constant temperature stirring tank at 60°C, and pre-react for 32 hours;

[0058] Step S3: Put the reaction precursor into the settling column. After the solid content in the reaction precursor is 8%, adjust the liquid pressure valve to 5MPa, use a pressure pump to pump it into the heat exchanger, and flow through the 250°C After the constant temperature heating zone, it passes through the heat exchanger again, reaches the liquid pressurization valve and flows out, and then washes and dries to obtain the magnesium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com