A separable induction heating furnace using hybrid spwm modulation technology

A technology of induction heating furnace and modulation technology, which is applied in induction heating, induction heating control, electric/magnetic/electromagnetic heating, etc., can solve the problems of low energy utilization rate, low heating efficiency, non-compliance with energy saving and emission reduction, etc. The effect of saving load matching transformer, high energy utilization rate and high heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

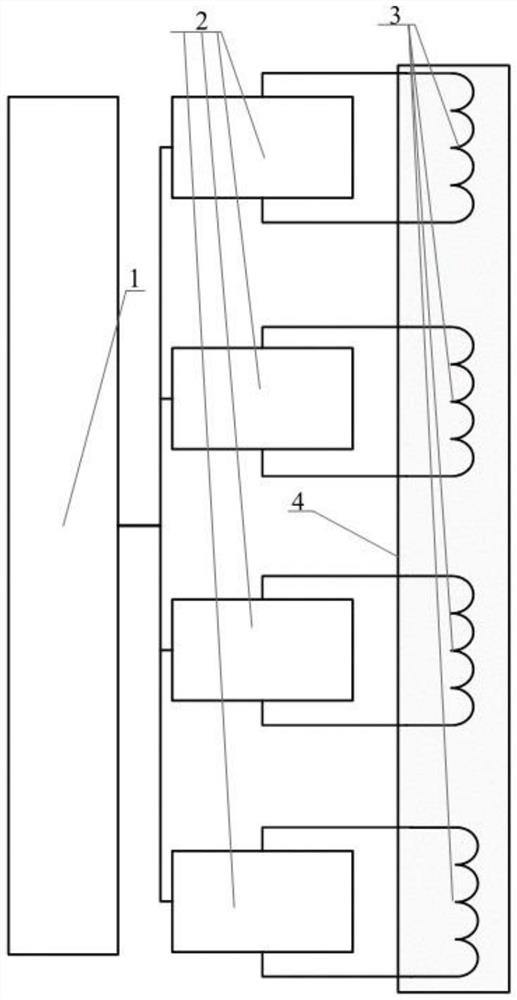

[0047] Such as figure 1 As shown, a separable induction heating furnace using hybrid SPWM modulation technology is mainly composed of the following parts: main zone induction furnace control unit 1, zone induction power supply control unit 2, induction heating coil 3, and furnace body 4. The induction furnace control unit 1 of the main area issues various instructions to the induction power control unit 2 of each area through the communication bus, and the induction power control unit 2 of each area outputs current to the heating coil 3 to heat the materials placed in the furnace body 4 .

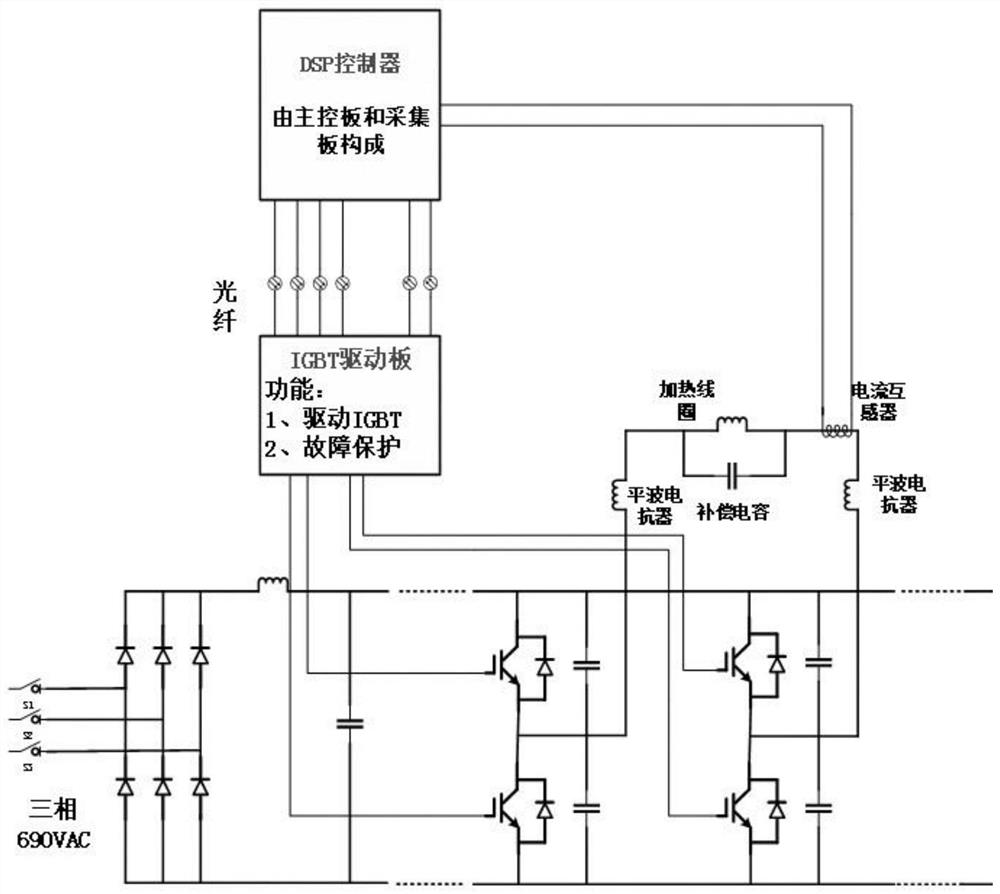

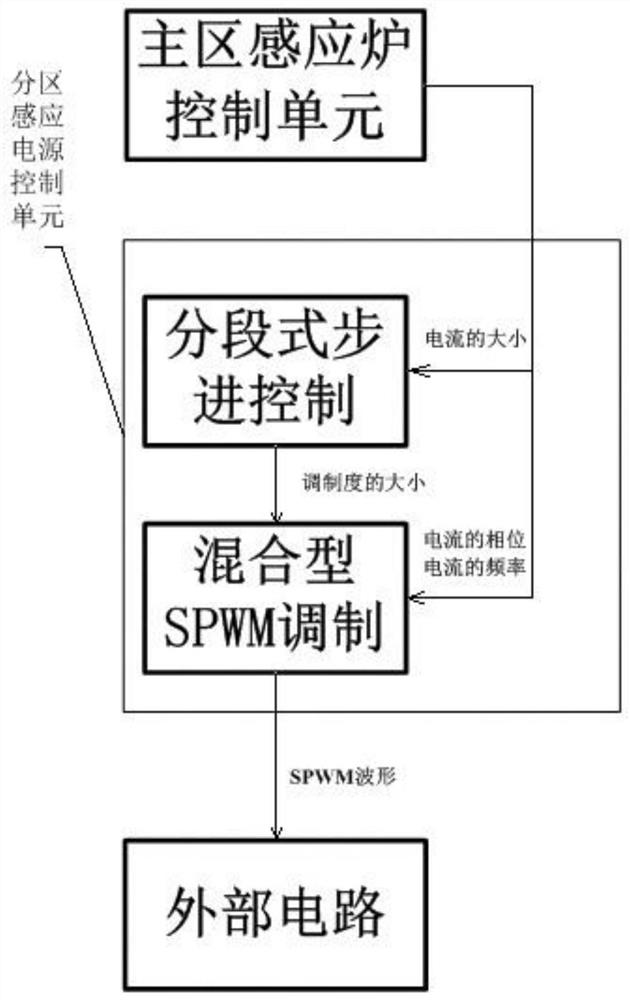

[0048] Such as figure 2 As shown, the partition induction power supply control unit 2 is mainly composed of an acquisition board, a main control board, and a driving board. The main control board is mainly responsible for the following functions: 1. Receive control instructions from the induction furnace control unit in the main area, generate SPWM signals as required, and output IGBT dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com