Method for removal of magnesium from phosphate rock and co-production of sodium fluorosilicate and magnesium sulfate

A technology of sodium fluorosilicate and magnesium sulfate, applied in magnesium sulfate, fluorosilicic acid, chemical instruments and methods, etc., can solve the problems of complex composition, environmental pollution, soil acidification, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

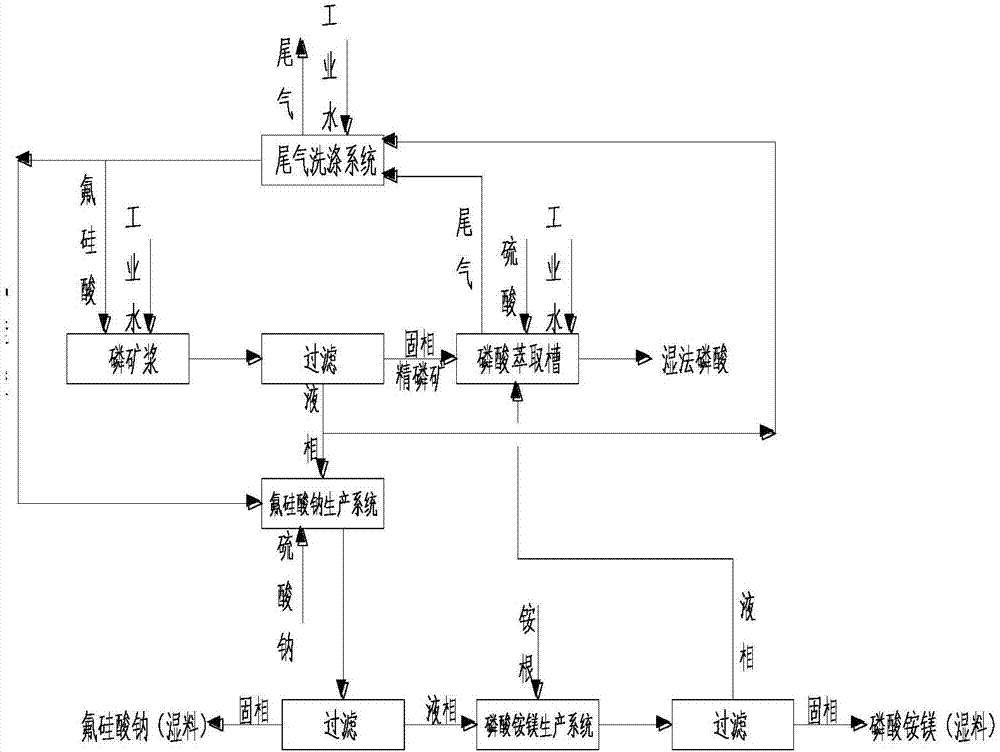

Image

Examples

Embodiment 1

[0063] A method for magnesium removal from phosphate rock and co-production of sodium fluorosilicate and magnesium sulfate, comprising the following steps:

[0064] (1) Magnesium removal: Add water to the phosphate rock to make a phosphate rock slurry with a content of 40%, pump it into the reaction tank, heat it to 45°C and keep it constant, and drop dilute fluosilicic acid with a concentration of 1 to 15mol / L at a constant speed Add it to the phosphate rock slurry, keep the pH constant at 1.0, react for 2 hours, separate the solid and liquid to obtain the filter cake and filtrate, wash the filter cake 2-3 times with water, and dry to obtain the phosphate concentrate; the washing liquid and the filtrate are mixed , sent to wet-process phosphoric acid production tail gas scrubbing and absorption system to prepare fluosilicic acid solution;

[0065] (2) Synthesis of sodium fluorosilicate: the content of 5% fluorosilicate solution in step (1) is sent to the sodium fluorosilicate...

Embodiment 2

[0068] A method for magnesium removal from phosphate rock and co-production of sodium fluorosilicate and magnesium sulfate, comprising the following steps:

[0069] (1) Magnesium removal: Add water to the phosphate rock to make a phosphate rock slurry with a content of 50%, pump it into the reaction tank, heat it to 65°C, and then add dilute fluosilicic acid with a concentration of 15mol / L dropwise at a constant speed to In the phosphate rock slurry, the pH is constant at 4.0, react for 5 hours, and separate the solid and liquid to obtain the filter cake and filtrate, and wash the filter cake 2-3 times with water, and dry to obtain phosphorus concentrate; the washing liquid and the filtrate are mixed and sent to Fluorosilicic acid solution is prepared in the tail gas scrubbing and absorption system of wet-process phosphoric acid production;

[0070] (2) Synthesis of sodium fluorosilicate: the content of 15% fluorosilicate solution in step (1) is sent to the sodium fluorosilica...

Embodiment 3

[0073] A method for magnesium removal from phosphate rock and co-production of sodium fluorosilicate and magnesium sulfate, comprising the following steps:

[0074] (1) Magnesium removal: Add water to the phosphate rock to make a phosphate rock slurry with a content of 45%, pump it into the reaction tank, heat it to 50°C and keep it constant, and drop dilute fluosilicic acid with a concentration of 1 to 15mol / L at a constant speed Add it to the phosphate rock slurry, keep the pH constant at 2.5, react for 3 hours, separate the solid and liquid to obtain the filter cake and filtrate, wash the filter cake 2-3 times with water, and dry to obtain the phosphate concentrate; the washing liquid and the filtrate are mixed , sent to wet-process phosphoric acid production tail gas scrubbing and absorption system to prepare fluosilicic acid solution;

[0075] (2) Synthesis of sodium fluorosilicate: the content of 10% fluorosilicate solution in step (1) is sent to the sodium fluorosilicat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com