Method for co-production of chemical synthetic fertilizer by industrial calcium products

A chemical synthesis and industrial technology, applied in chemical instruments and methods, calcium/strontium/barium compounds, inorganic chemistry, etc., can solve problems such as secondary pollution, and achieve the goal of accelerating enterprise transformation, improving product structure, and reducing solid waste emissions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

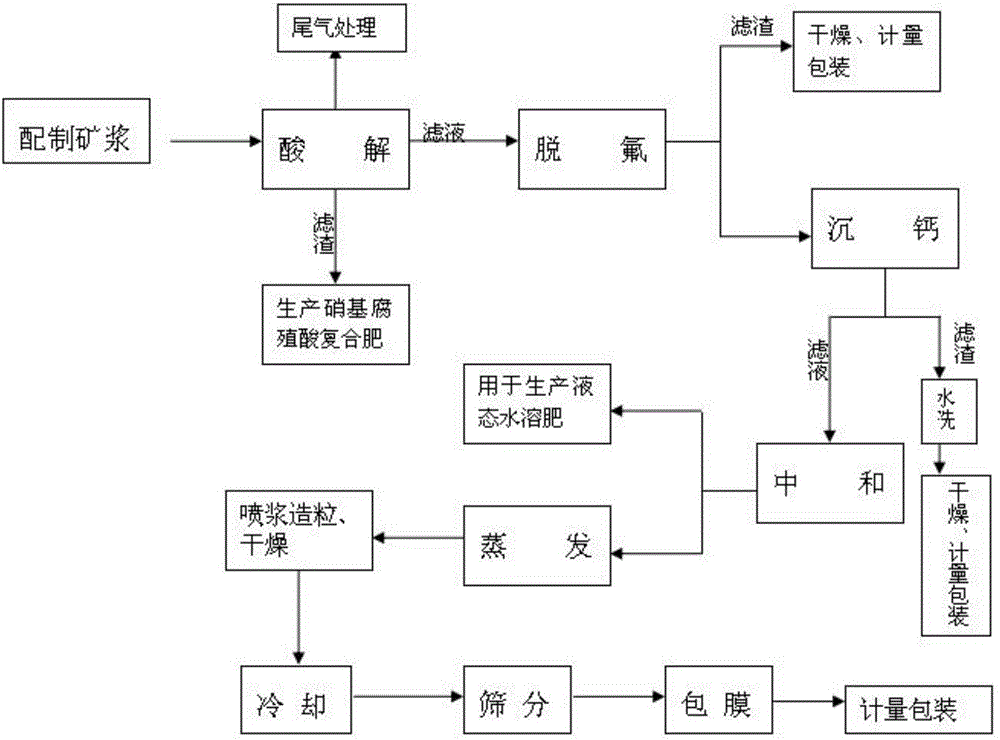

[0030] Such as figure 1 Shown, prepare technical grade calcium sulfate and binary chemical synthetic fertilizer according to the following methods:

[0031] 1. Analysis of main components of phosphate rock:

[0032] composition content composition content P 2 o 5

29% Fe 2 o 3

1.07% MgO 2.5% CaO 50% al 2 o 3

2.3% acid insoluble matter 6.13% h 2 o

5% F -

4.67%

[0033] 2. Mix 1 ton of mineral powder into 1.54 tons of slurry.

[0034] 3. Add 1.54 tons of ore pulp obtained in step 2 and 2628.8 kilograms of nitric acid solution and 3 kilograms of urea with a concentration of 50% in the acidolysis tank in the raw material slurry method production line. The reaction time was 1.5 hours, and the reaction temperature was 60°C.

[0035] 4. After the reaction is completed, filter. The filter residue is sent to the compound fertilizer workshop, and the filtrate is sent to the defluorination tank in the raw ...

Embodiment 2

[0044] Prepare industrial-grade calcium carbonate and chemically synthesized compound fertilizers as follows:

[0045] 1. Analysis of main components of phosphate rock:

[0046] composition content composition content P 2 o 5

27.83% Fe 2 o 3

0.86% MgO 2.6% CaO 48.92% al 2 o 3

2.27% acid insoluble matter 6.27% h 2 o

5% F -

3.98%

[0047] 2. Mix 1 ton of mineral powder into 1.515 tons of slurry.

[0048] 3. Add 1.515 tons of ore pulp of step 2 gained and concentration of 48% nitric acid solution 2625 kg and 4 kg of urea respectively to the acidolysis tank in the raw material slurry method production line. The reaction time was 2 hours, and the reaction temperature was 58°C.

[0049] 4. After the reaction is completed, filter. The filter residue is sent to the compound fertilizer workshop, and the filtrate is sent to the defluorination tank in the raw material slurry production line.

[0050] 5. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com