Semiconductor package substrate increasing static dissipation capability

A technology for packaging substrates and static dissipation, which is applied in semiconductor devices, semiconductor/solid-state device components, electric solid-state devices, etc., and can solve the problems of general products without structure, changing design structure, and inconvenience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

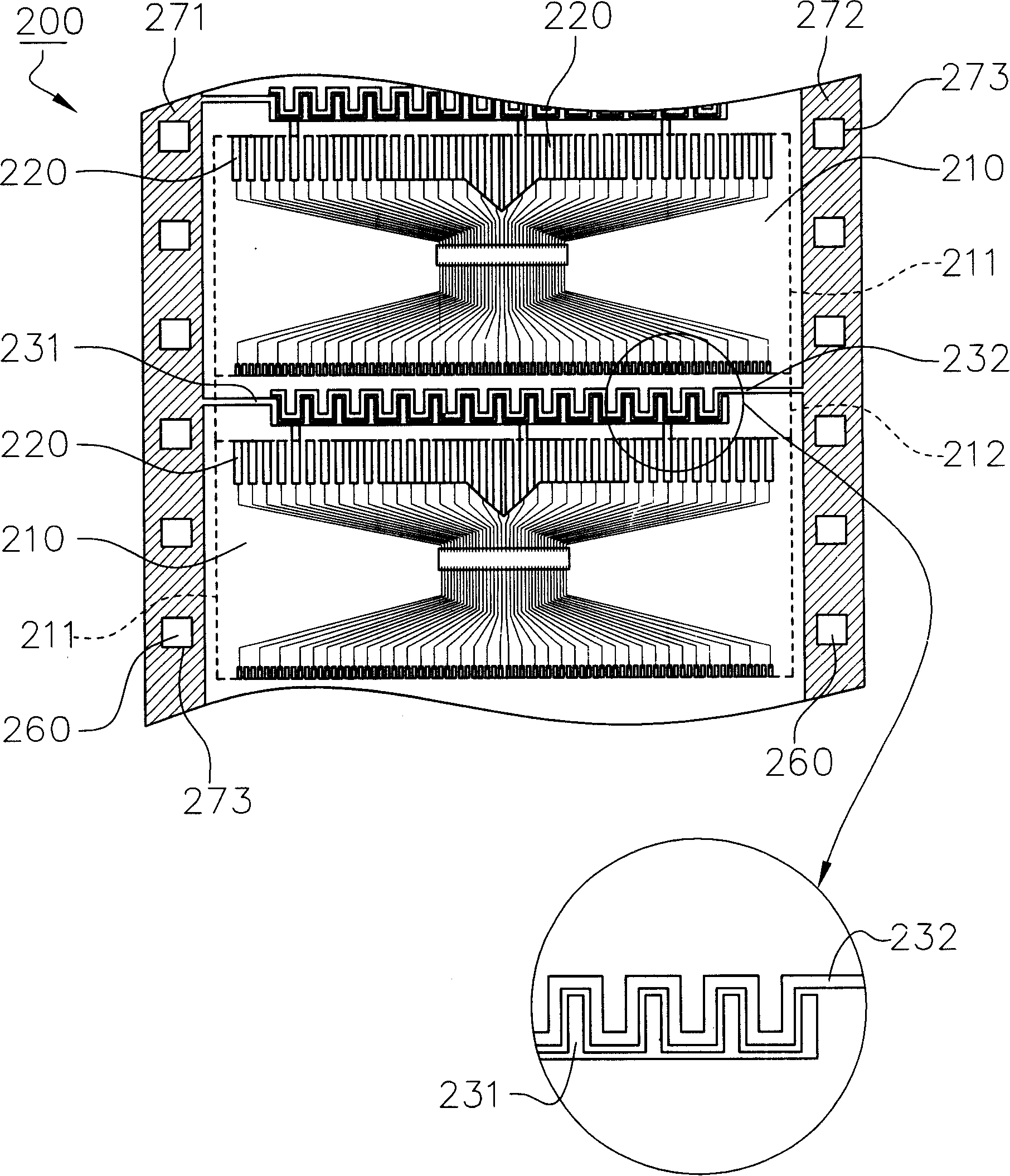

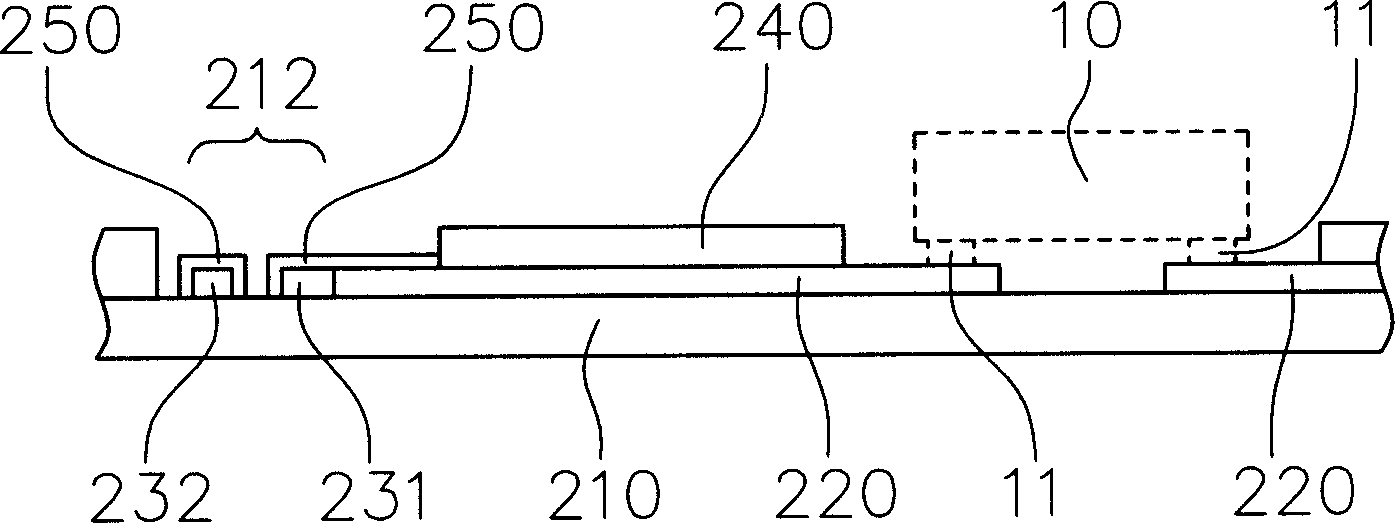

[0059] According to a first embodiment of the present invention, a semiconductor package substrate is disclosed. Such as figure 2 and image 3 As shown, the semiconductor package substrate 200 mainly includes a dielectric layer 210 , a plurality of pins 220 , a plurality of first electrostatic guiding lines 231 , a plurality of second electrostatic guiding lines 232 and a solder resist layer 240 . A surface of the dielectric layer 210 defines a plurality of packaging units 211 and a plurality of static dissipative regions 212 . After the packaging process, a semiconductor package structure can be cut out along the periphery of the package units 211 . Generally, these encapsulation units 211 can also be referred to as use areas. The static dissipative area 212 is located between or on the side of the packaging unit 211, and is used to disperse the static charge of the grounding pin or the pin with weak static resistance in these static dissipative areas 212 exposed outside ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com