Patents

Literature

196results about How to "Simple product structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rapid long-acting humic acid multivariate fertilizer and production method thereof

The invention discloses a rapid long-acting humic acid multivariate fertilizer and a production method thereof. A long-acting part of the rapid long-acting humic acid multivariate fertilizer comprises raw materials of, by weight, 15-20% of urea, 5-10% of ammonium sulfate, 5-10% of ammonium chloride, 5-15% of monoammonium phosphate, 8-15% of calcium magnesium phosphate, 10-20% of potassium chloride or potassium sulfate, 10-15% of waste residues left from iron selection of pyrite smelting slag, 25-50% of humic acid, 5-25% of phosphogypsum and 5-12% of dolomite powder; A rapid part comprises rawmaterials of, by weight, humic acid urea prepared from 20-30% of urea and 40-50% of instant humic acid, 5-15% of monoammonium phosphate, 10-20% of potassium chloride or potassium sulfate, 0.5-1% of borax, 1-3% of zinc sulfate, 2-5% of magnesium sulfate, 0.2-1% of copper sulfate and 0.01-0.05% of ammonium molybdate.

Owner:GUIZHOU TIANDIFU FERTILIZER

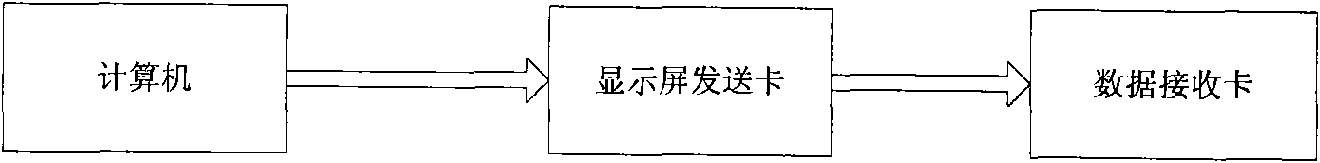

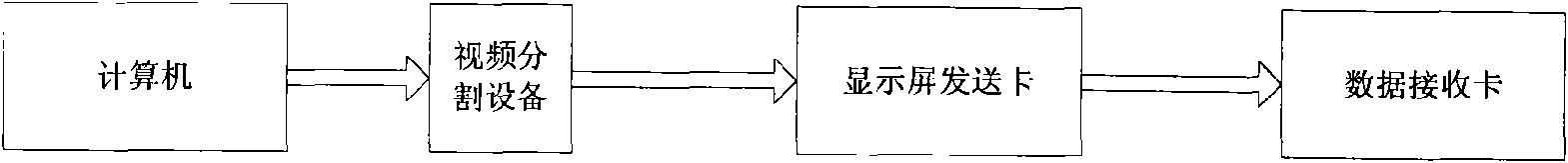

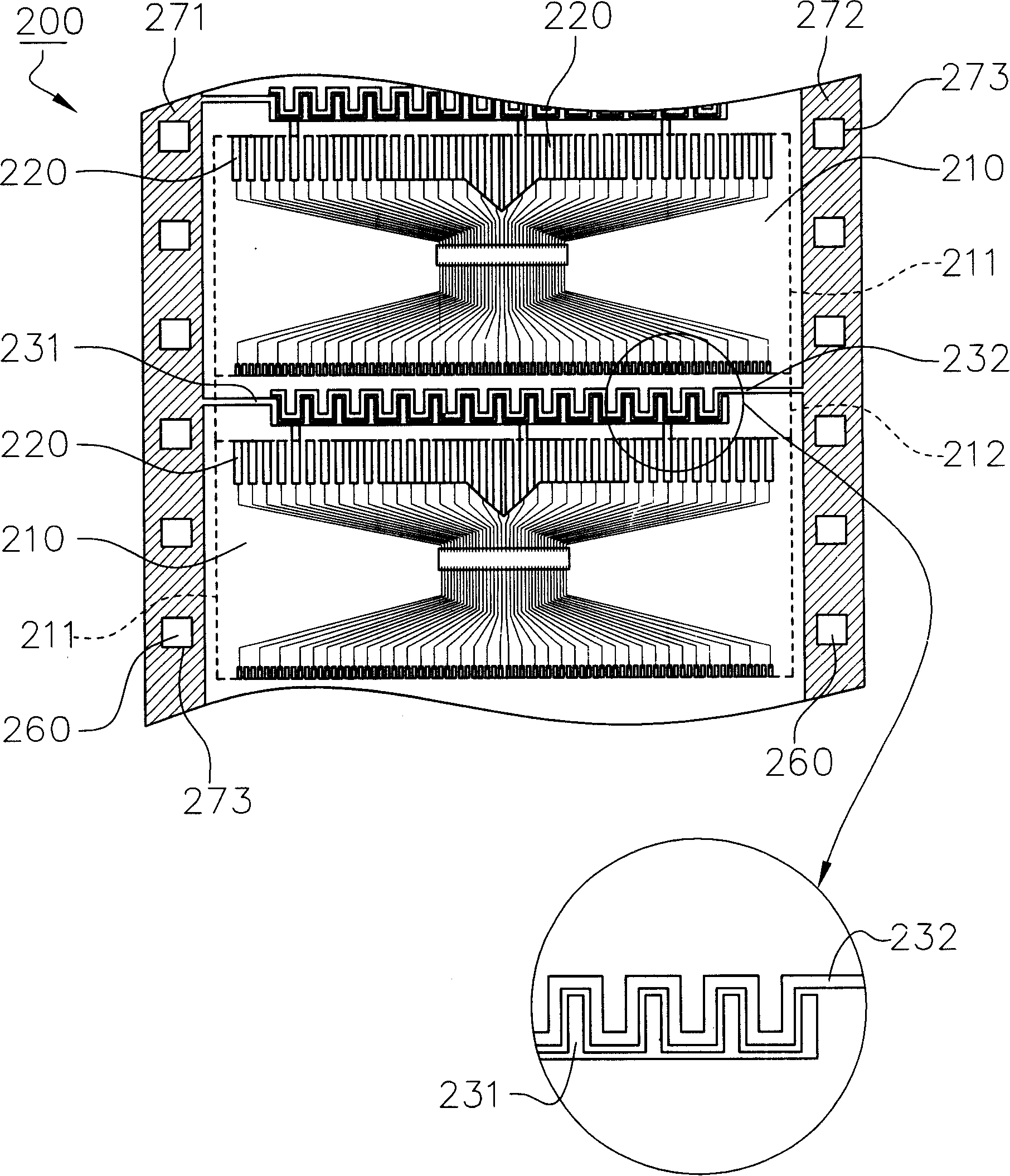

System and method for controlling high-resolution LED display screen

ActiveCN101567162AMeet the needs of resolutionLow costStatic indicating devicesDigital videoLED display

The invention discloses a system and a method for controlling a high-resolution LED display screen. An LED video controller is connected with a computer; a data allocator is connected with the LED video controller; a module control panel is connected with the data allocator; the LED display module is connected with the module control panel; a DVI digital video signal output by the computer enters the LED video controller; the LED video controller transmits the DVI digital video signal to the data allocator and uploads the state of the display screen to the computer in real time; the data allocator transmits the DVI digital video signals to each row of the module control panel; and the module control panel drives the LED display module for displaying. The invention has large improvement on the product structure, the method or the functions, has remarkable advancement on the technology, generates good and practical effect and is more suitable for practicality.

Owner:XIAN NOVASTAR TECH

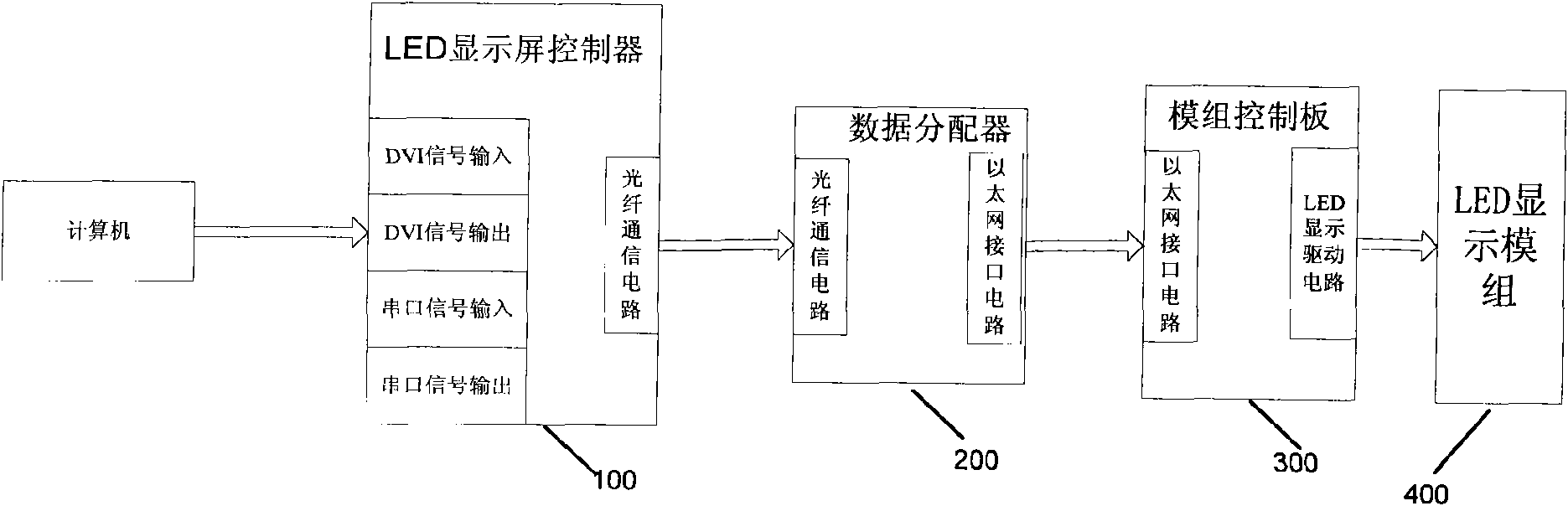

Novel process for producing valine

ActiveCN101580475AReduce pressure on environmental protectionReduce lossesOrganic compound preparationSolid sorbent liquid separationMicroorganismUltrafiltration

The invention discloses a novel process for producing valine, which comprises the following steps: obtaining a valine zymotic fluid by a microbiological fermentation method, removing impurities such as thalli through an ultrafiltration membrane, concentrating and crystallizing to obtain a crude product of the valine, and performing spray drying on mother solution to produce a feed grade product; performing acid dissolution and recrystallization on the crude product of the valine, dissolving the obtained product by 10 to 15 times of water, then producing a pharmaceutical product through ion exchange treatment, decolorization by an eluent and crystallization, and then circularly using a mother solution through the ion exchange treatment; and diluting the mother solution obtained after the re-crystallization of the crude product, then producing a food grade product through ion exchange by the mother solution, and then circularly using the mother solution through the ion exchange treatment. The process greatly improves the total extraction yield of products, produces different levels of products to meet different demands of the market, and reduces environmental pollution by recoveringand reutilizing partial wastewater generated during the ion exchange.

Owner:JIANGSU SHENHUA PHARMA

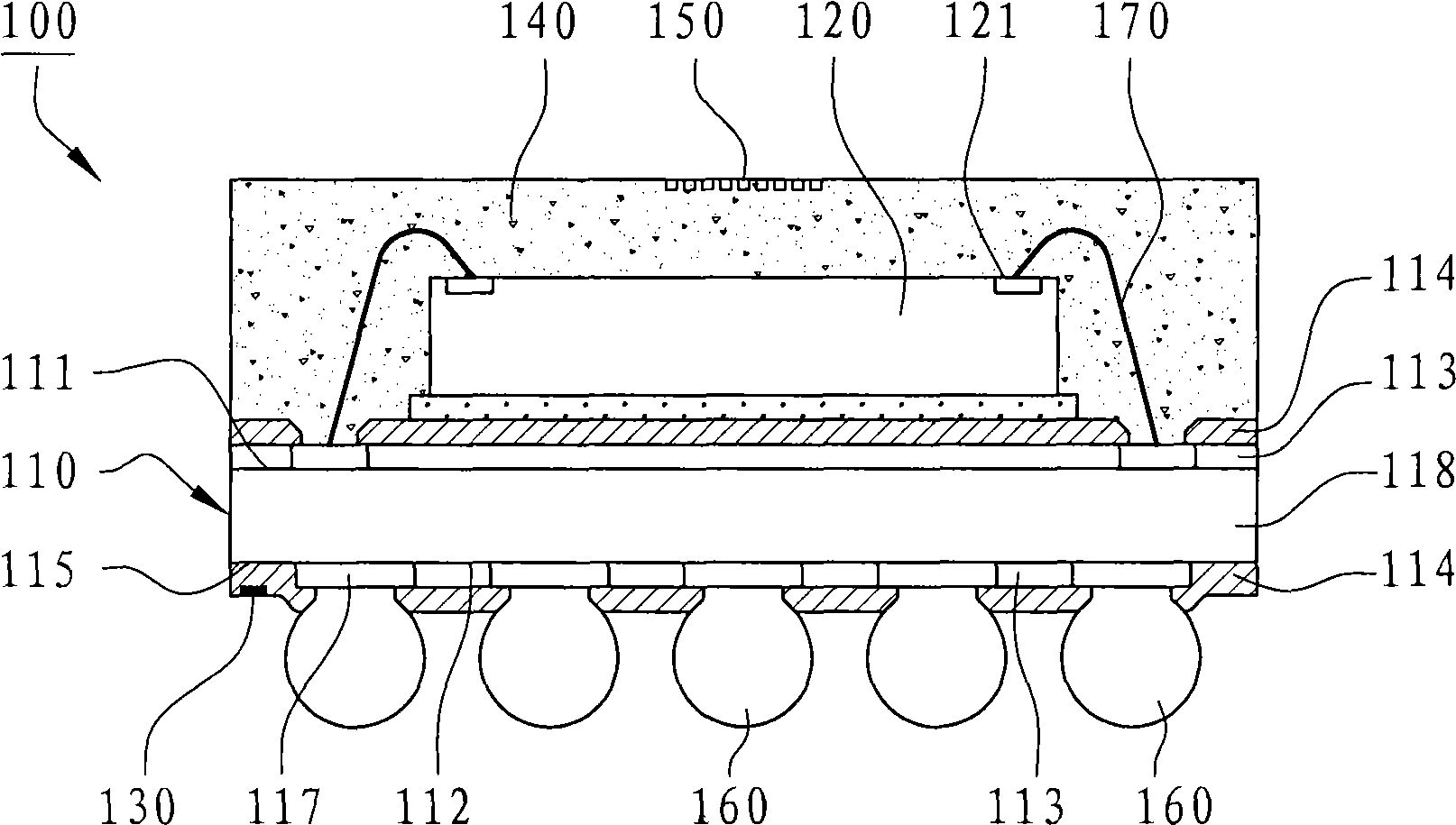

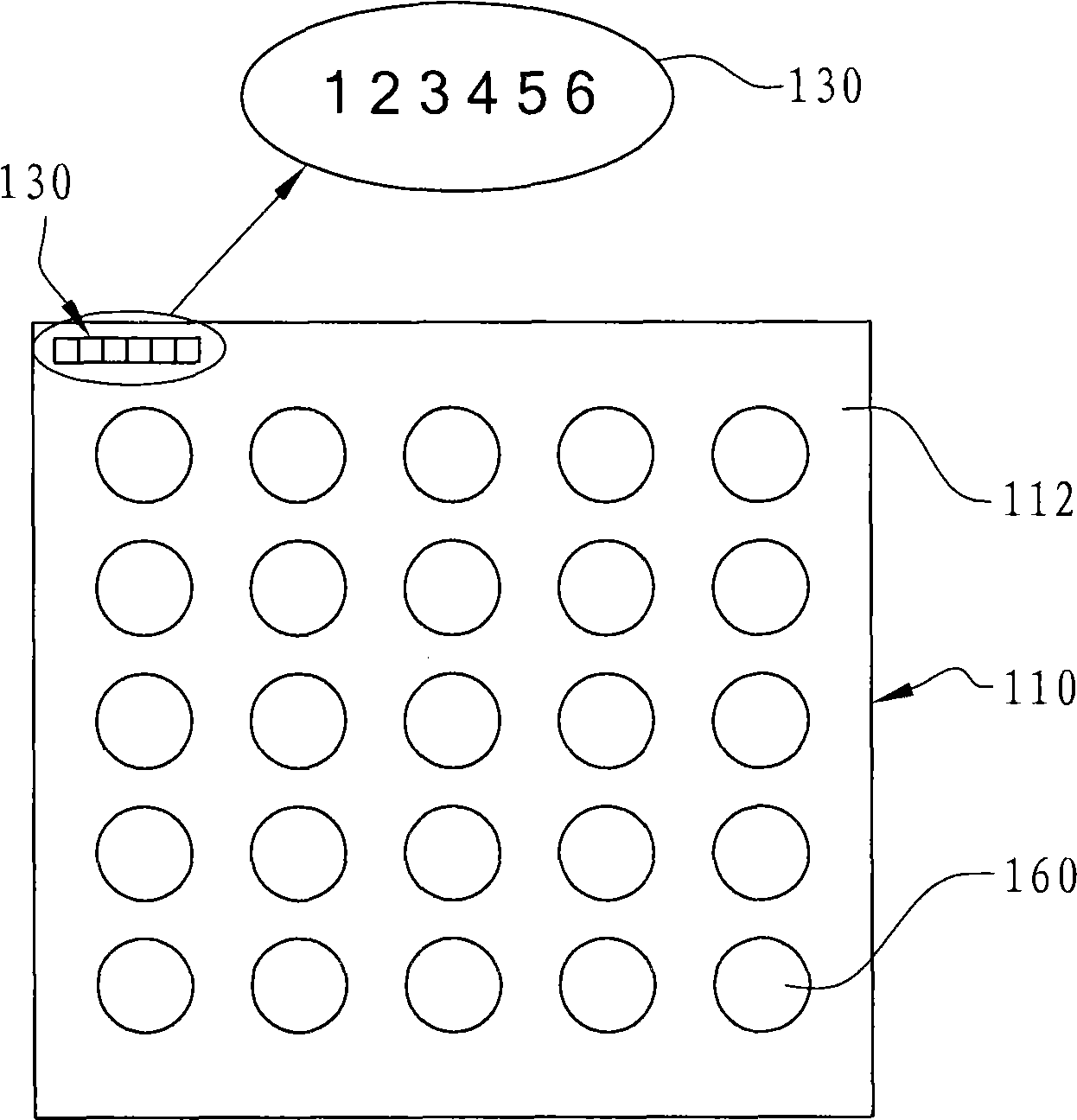

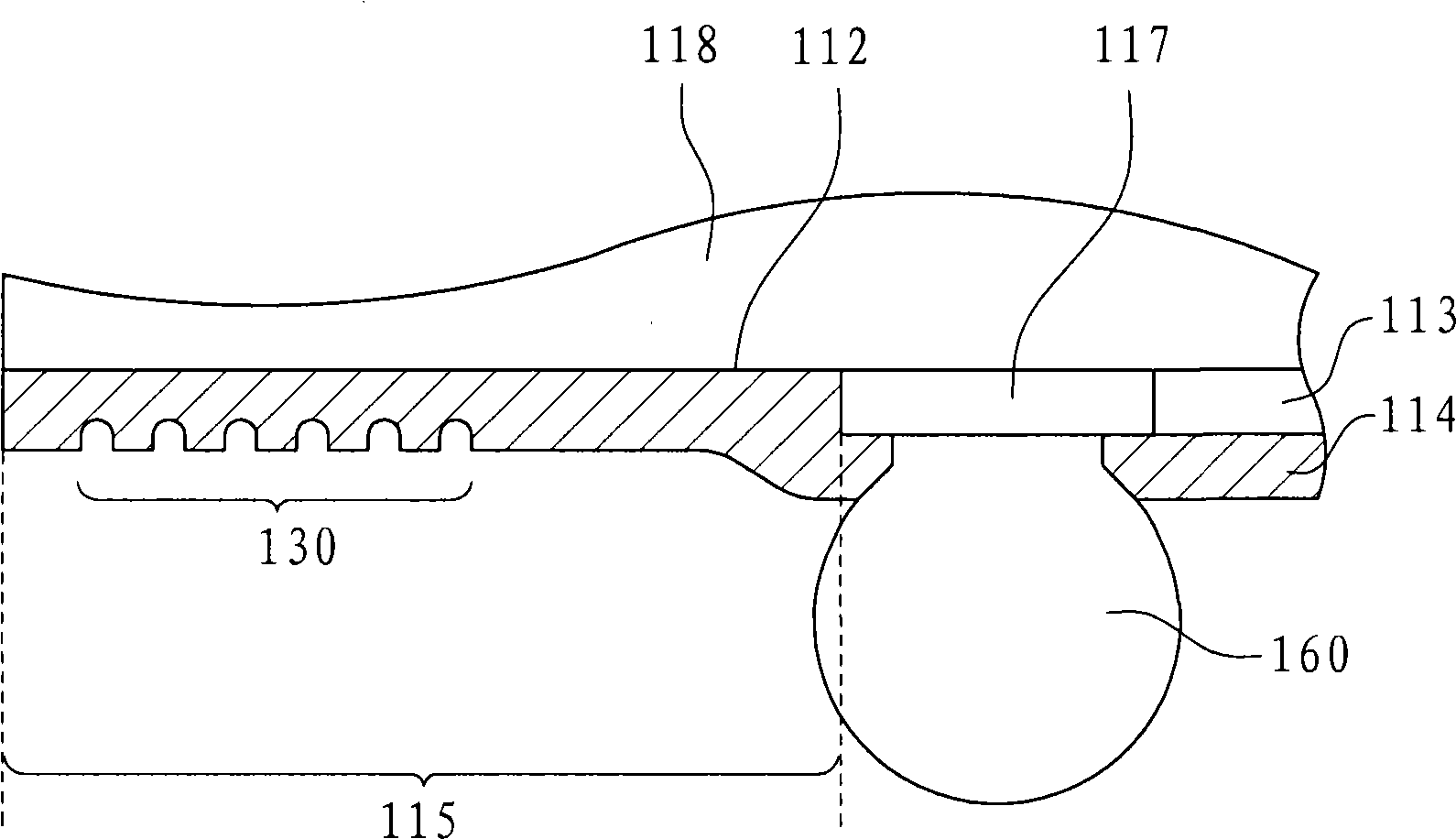

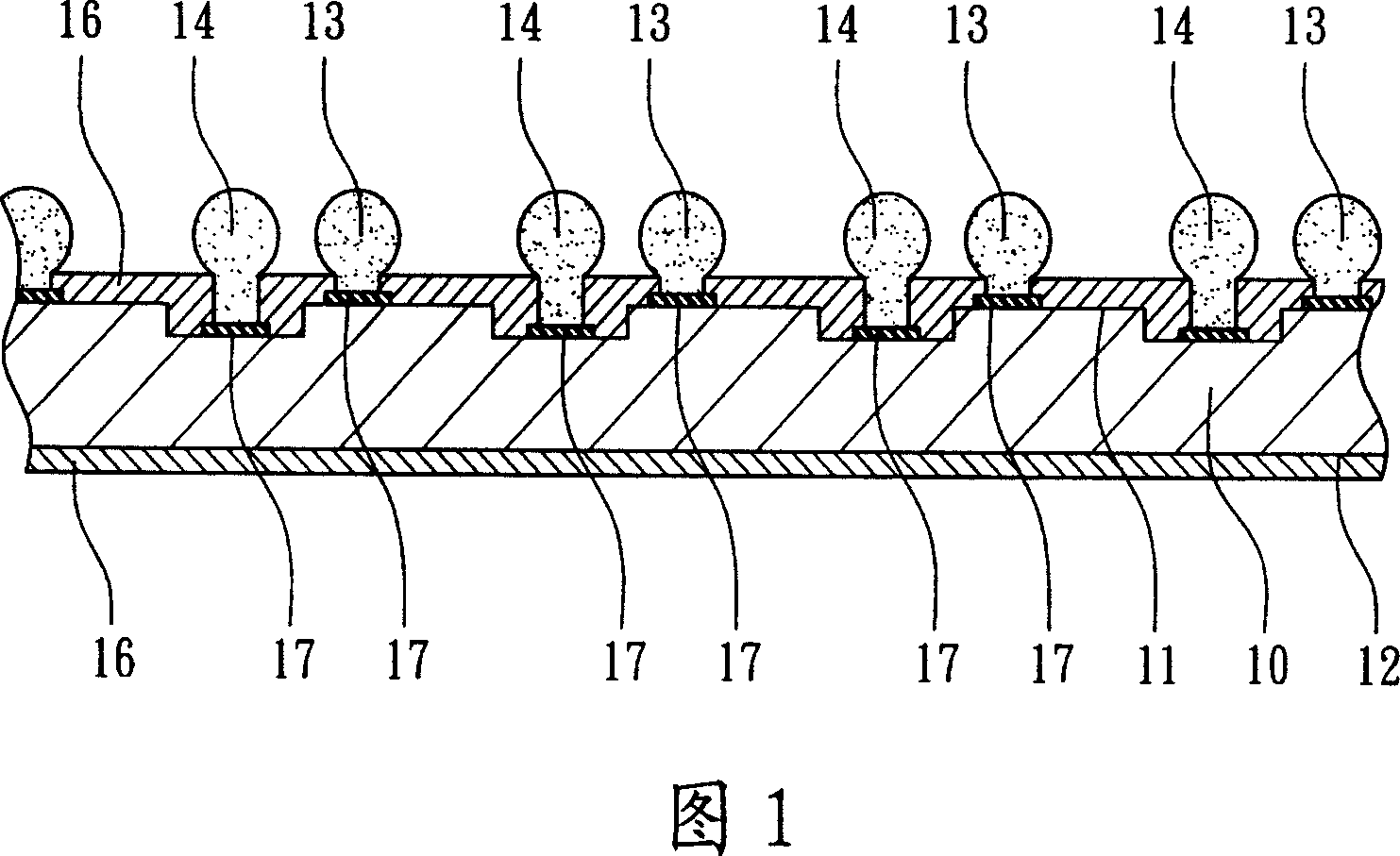

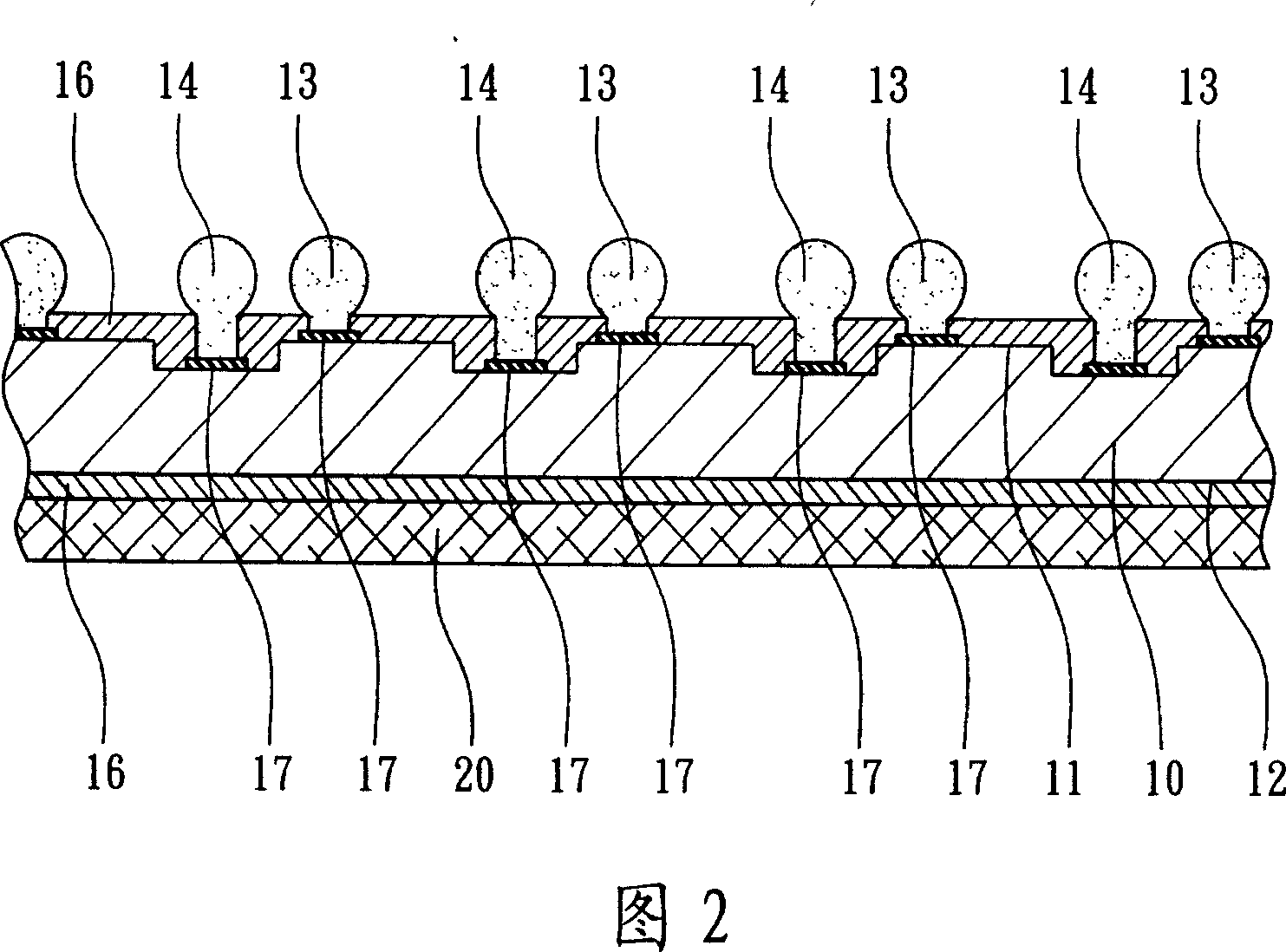

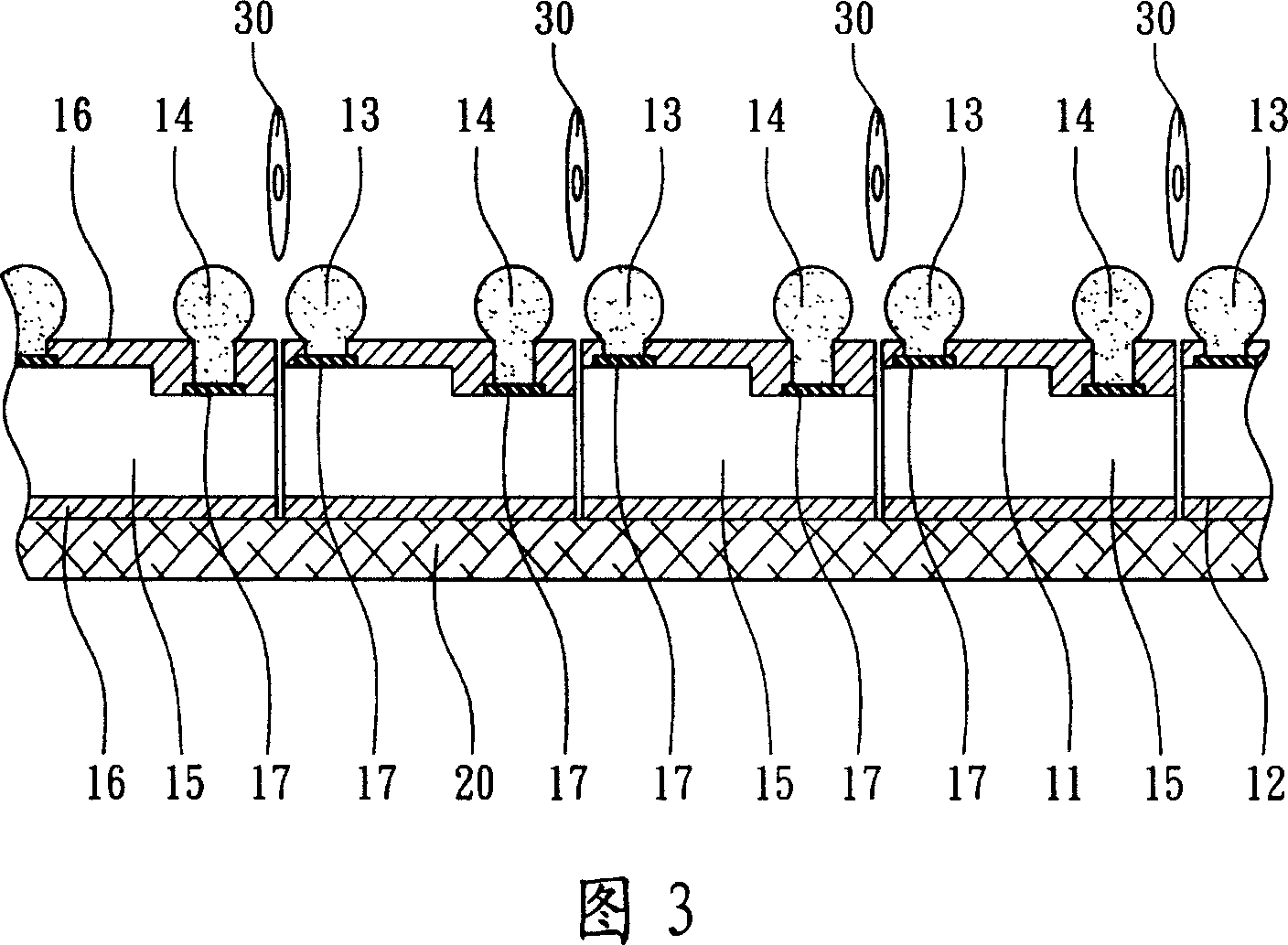

Semiconductor encapsulation structure having substrate identification code and manufacturing method thereof

InactiveCN101488492AWon't hurtConvenienceSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageQuality control

The invention relates to a semiconductor encapsulation construct with a base plate identification code and a manufacturing method thereof. The lower surface of a base plate is formed with a circuit layer and a welding cover layer which roughly covers the circuit layer and a non circuit area. A wafer is arranged on the upper surface of the base plate. The base plate identification code escapes the circuit layer, is formed on the welding cover layer of the base plate or an adhesive body by laser marking and is used for marking product batch of the base plate. Therefore, the product batch can be traced by the encapsulation construct, and the encapsulation construct can be used for quality control and abnormal tracing while the appearance is not needed to be changed. In addition, the base plate identification code can be formed by utilizing the existing laser marking board for semiconductor encapsulation and the laser marking, thus being convenient for manufacture and not damaging the circuit layer of the base plate.

Owner:POWERTECH TECHNOLOGY

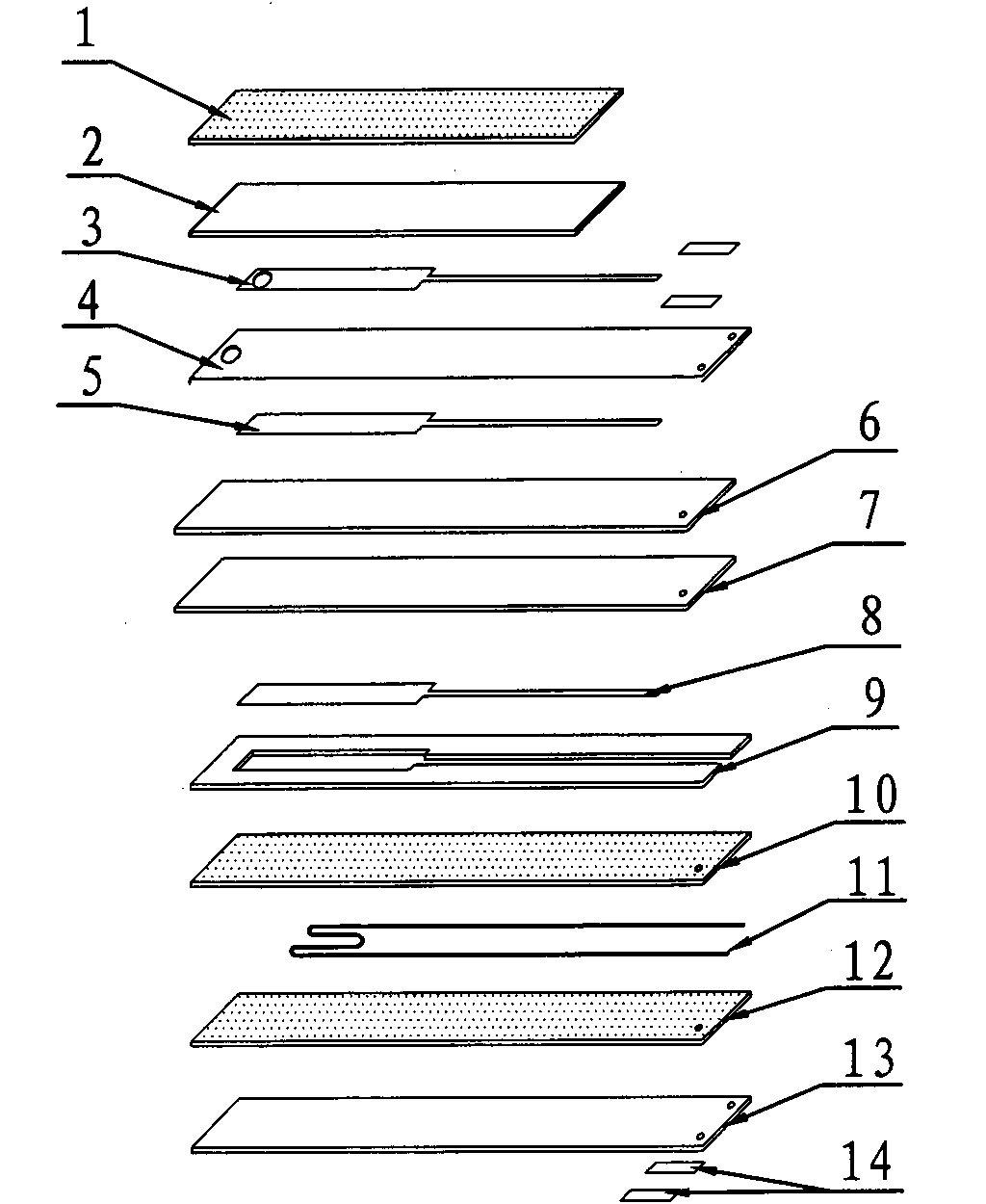

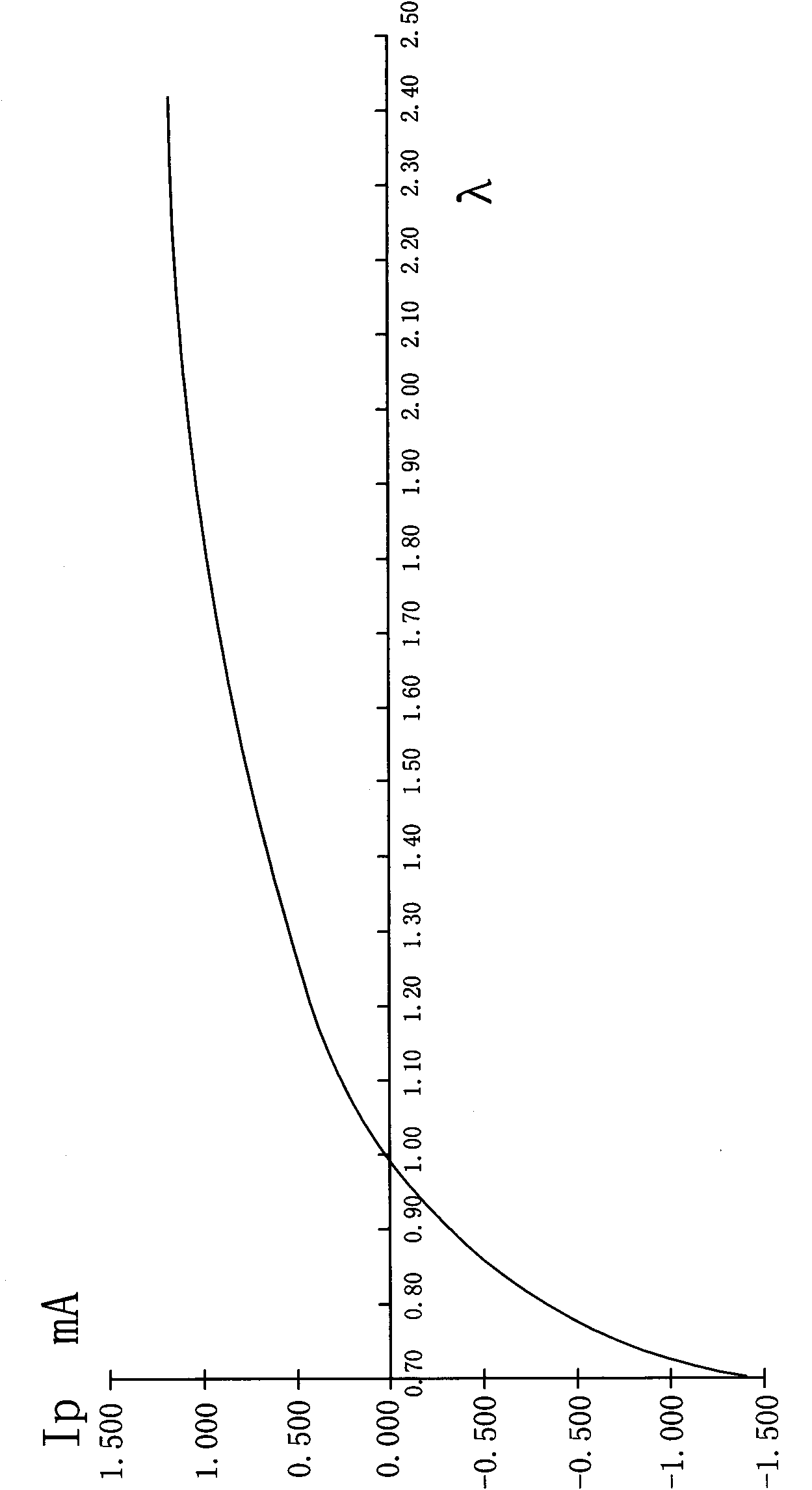

Automobile chip wide domain oxygen sensor using standard signal output

ActiveCN101943675AReduce crackingSimple product structureMaterial electrochemical variablesYttriumMagnesium

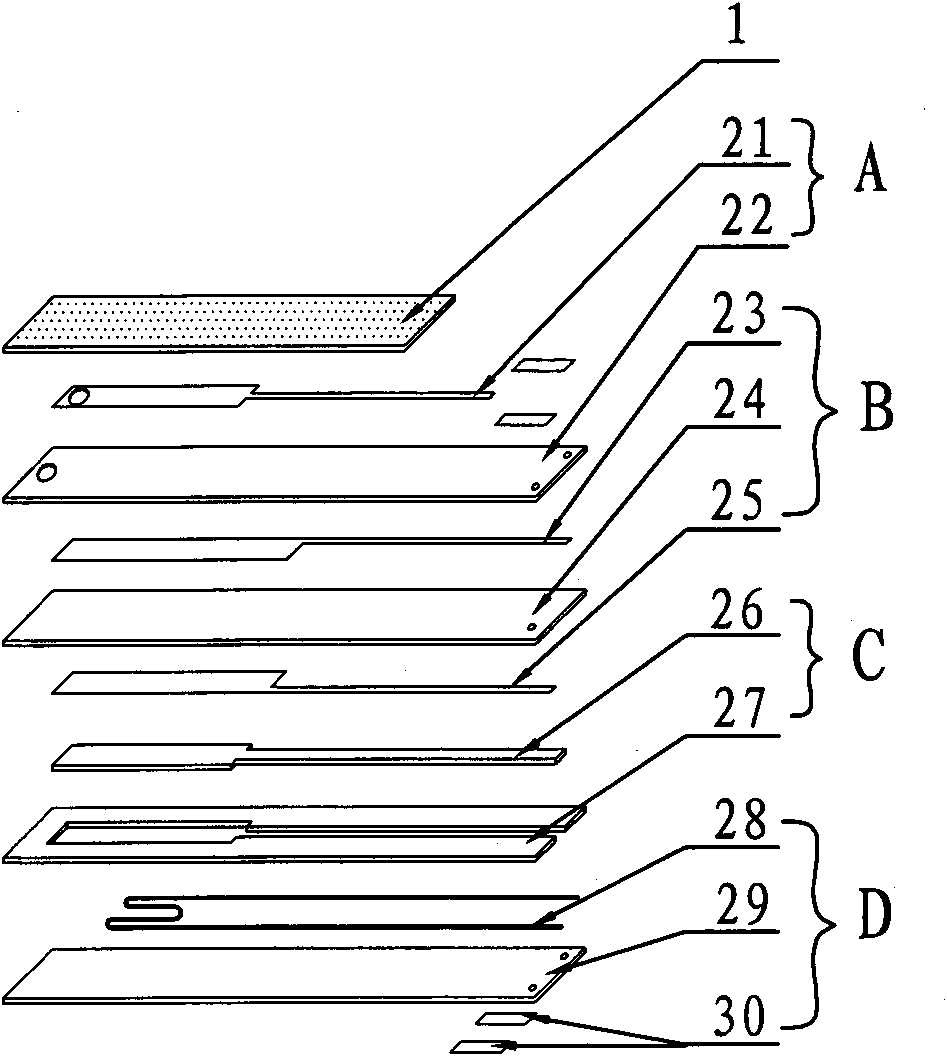

The invention provides an automobile chip wide domain oxygen sensor using standard signal output, which consists of a porous protective layer, an oxygen pump external electrode, an oxygen pump matrix layer, an oxygen pump internal electrode, a reaction matrix layer, an inner reaction electrode layer, a multilayer ceramic gas exchange layer, an upper heating matrix layer, a heating electrode layer, a lower heating matrix layer and heating electrode pins, wherein, the oxygen pump matrix layer and the reaction matrix layer are zirconium oxide substrates stabilized by yttrium oxide; the multilayer ceramic gas exchange layer, the upper heating matrix layer and the lower heating matrix layer are substrates made by compounding aluminum oxide, magnesium oxide and barium oxide according to a certain proportion; and the layers are printed with electrodes, laminated and integrated together by a sintering mode. The substrates made from the aluminum oxide, the magnesium oxide and the barium oxide has good insulating property and the same sintering temperature and thermal expansion coefficient as zirconium oxide, thus lowering possibility that the layers of the automobile oxygen sensor are cracked and disabled owing to thermal shock; and the substrates have good insulating strength, thus reducing interference of voltage of heating electrodes on a signal circuit.

Owner:JINTAN JONSSEN ELECTRIC TECH CORP

Process for producing fruit juice powder using dahlia as raw material

A process for preparing the powdered fruit juice from dahlia includes such steps as clearing the chosen dahlia fruit, squeezing, beating, proportionally adding dextrin, stirring, centrifugal spray drying for 5-40 S, and packing in low-humidity room. It features no damage to smell and nutrients.

Owner:江城绿色版纳生态食品有限公司

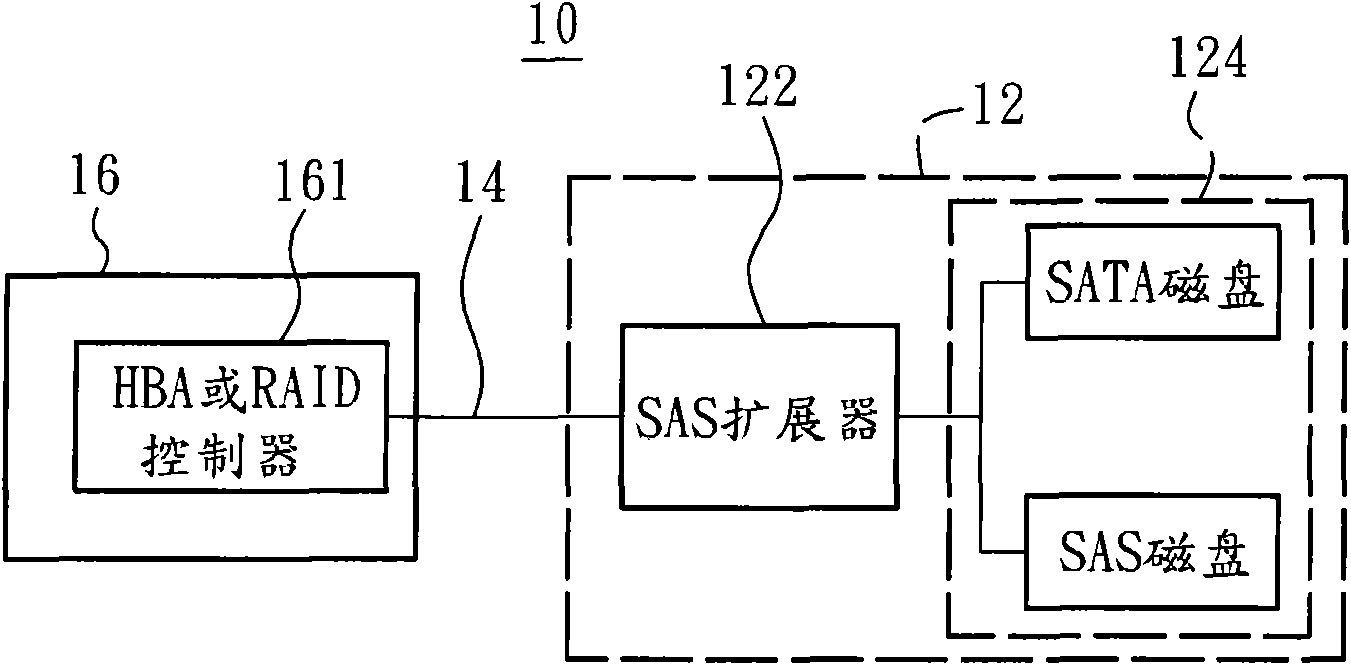

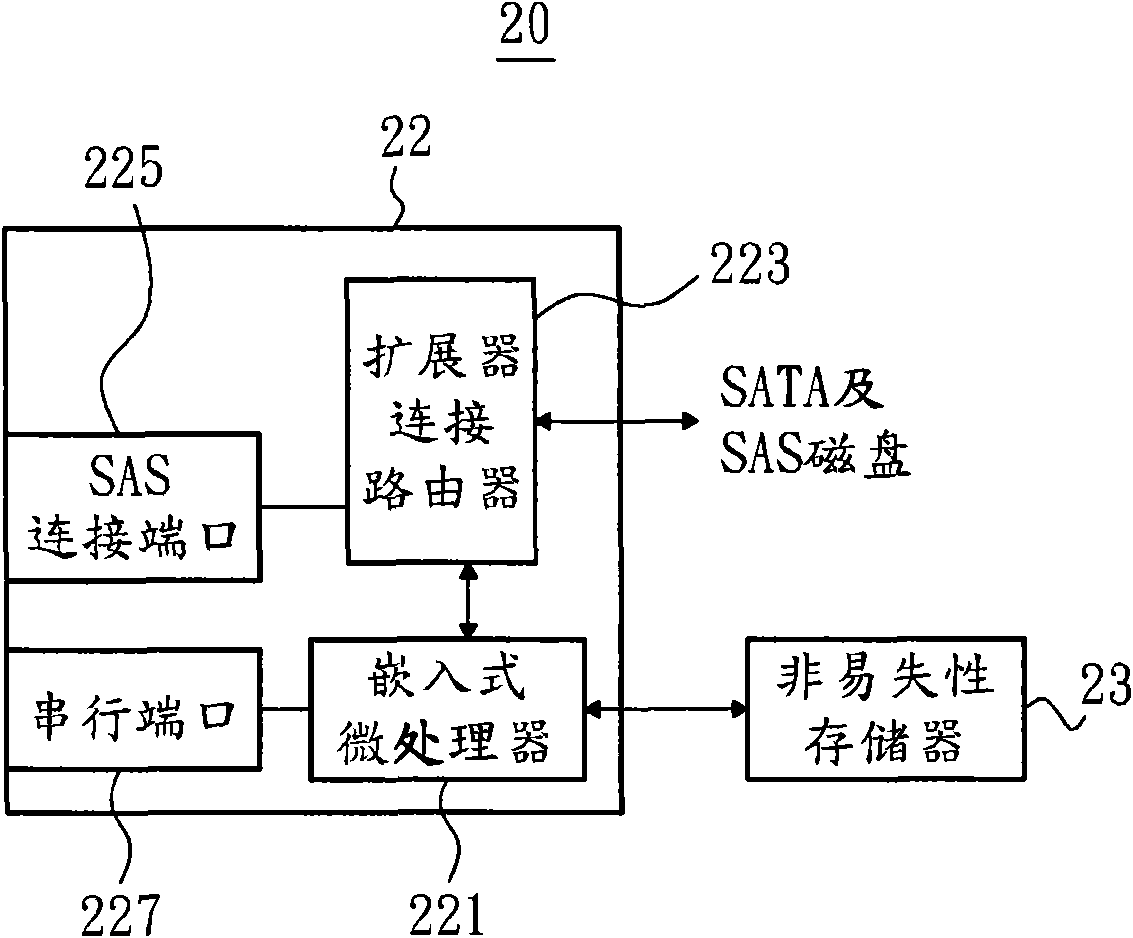

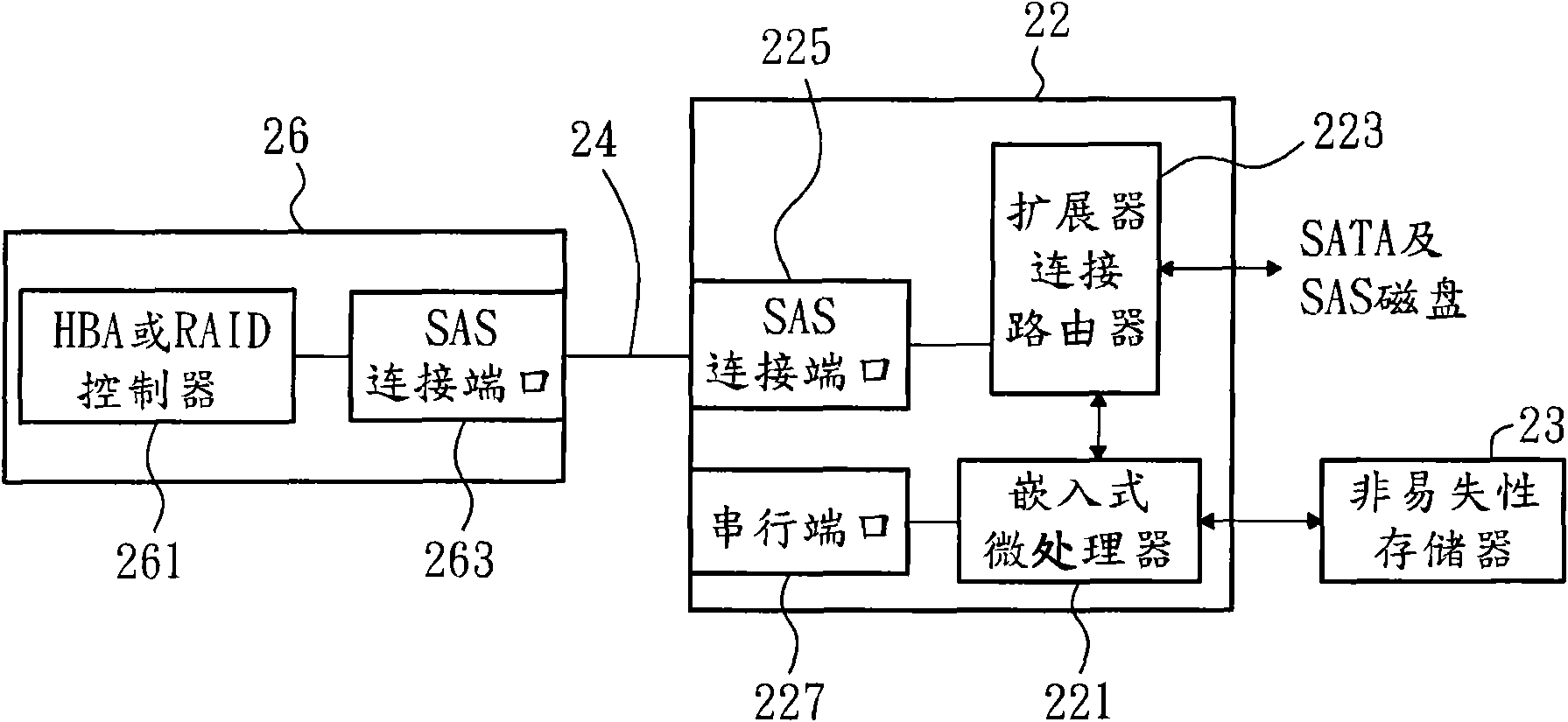

Updating device and updating method of magnetic disk firmware

InactiveCN101944029AShorten update timeImprove update efficiencyInput/output to record carriersProgram loading/initiatingSCSISerial advanced technology attachment

The invention provides updating device and updating method of magnetic disk firmware. The updating device of the magnetic disk firmware comprises an SAS (Serial Attached SCSI) expander and a nonvolatile memory, wherein the SAS expander comprises an expander connecting router and an embedded microprocessor, the expander connecting router is used for connecting an SATA (Serial Advanced Technology Attachment) magnetic disk and an SAS magnetic disk, the embedded microprocessor is electrically coupled with the expander connecting router, and an SATA host controller driving program and an SCSI (Small Computer System Interface) starter driving program are loaded in the embedded microprocessor; and the nonvolatile memory is electrically coupled to the embedded microprocessor and used for storing the magnetic disk firmware to be updated, the SATA host controller driving program or the SCSI starter driving program is selectively called by the magnetic disk firmware through the embedded microprocessor and sent to a specific magnetic disk for firmware updating through the expander connecting router. The invention can improve the updating efficiency when carrying out firmware updating of the magnetic disk.

Owner:UNIVERSAL SCIENTIFIC INDUSTRIAL (SHANGHAI) CO LTD

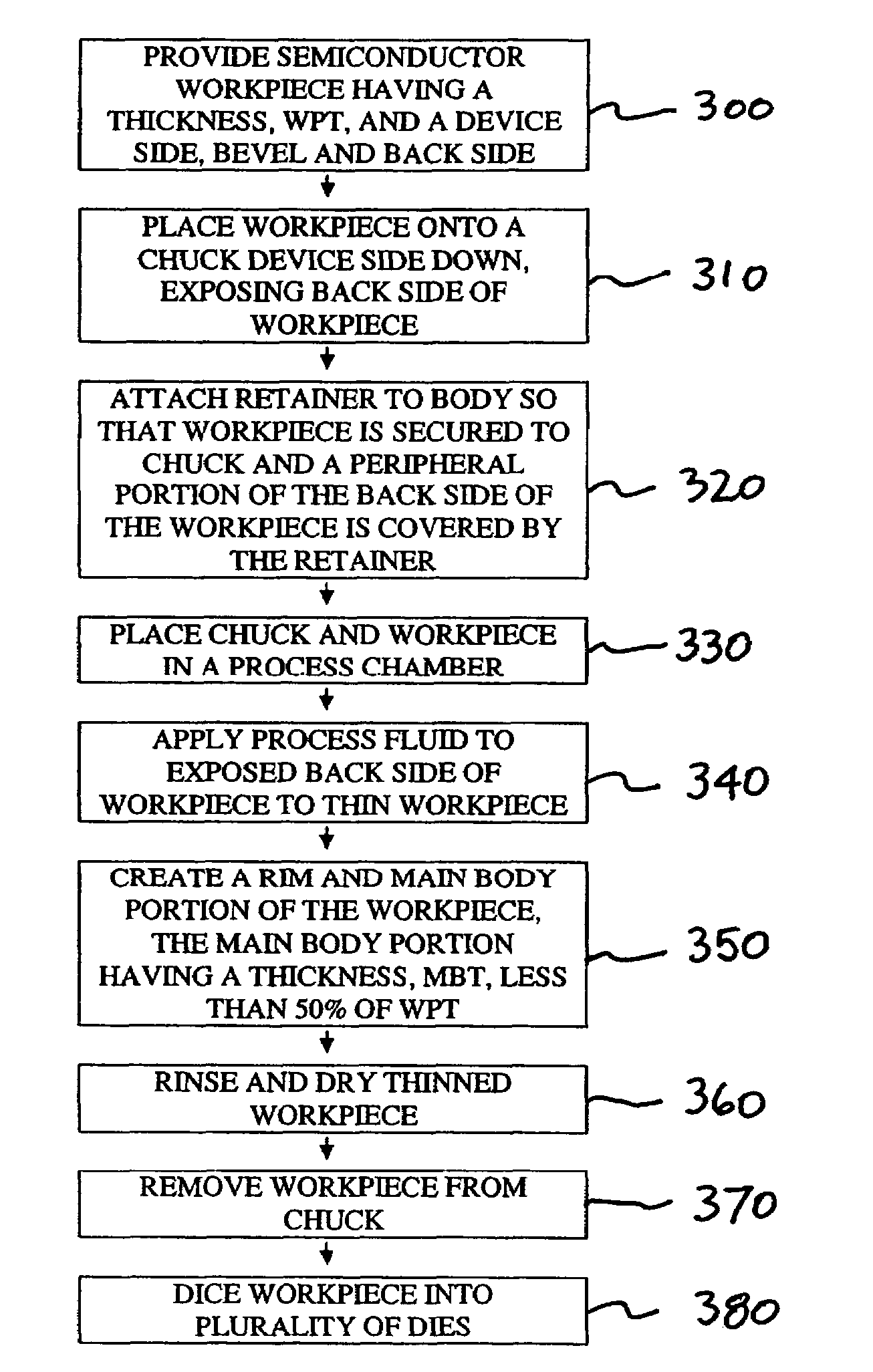

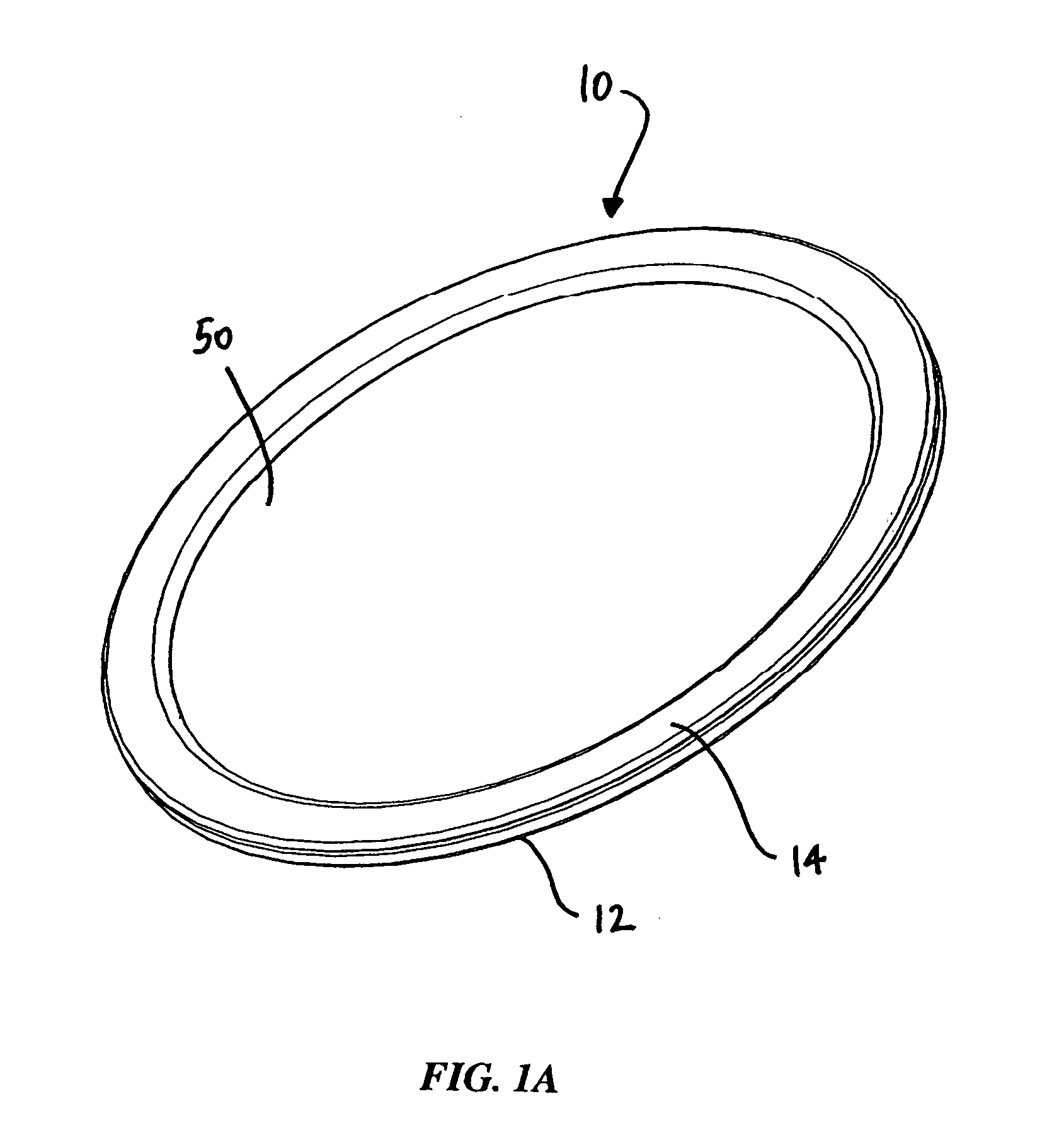

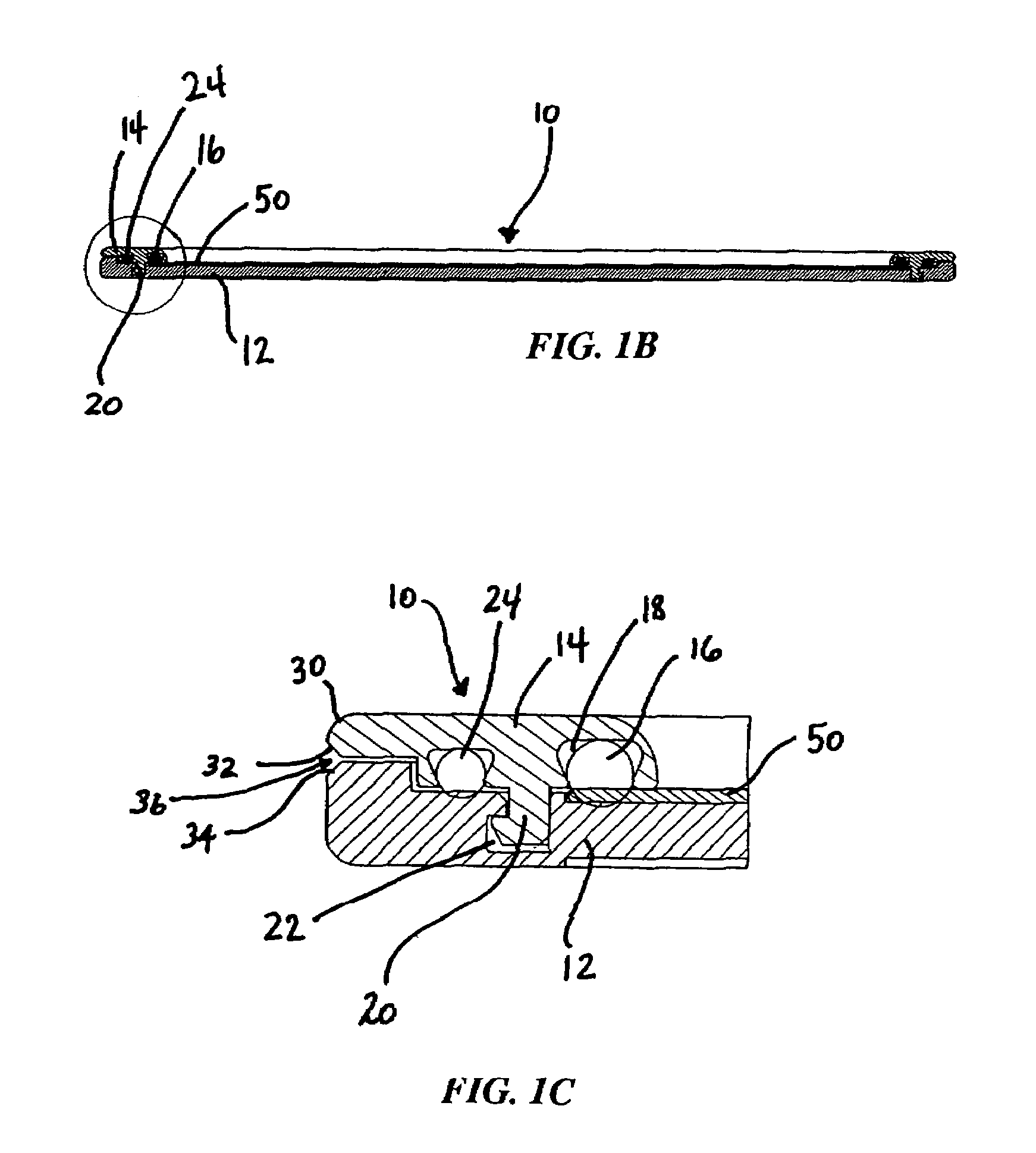

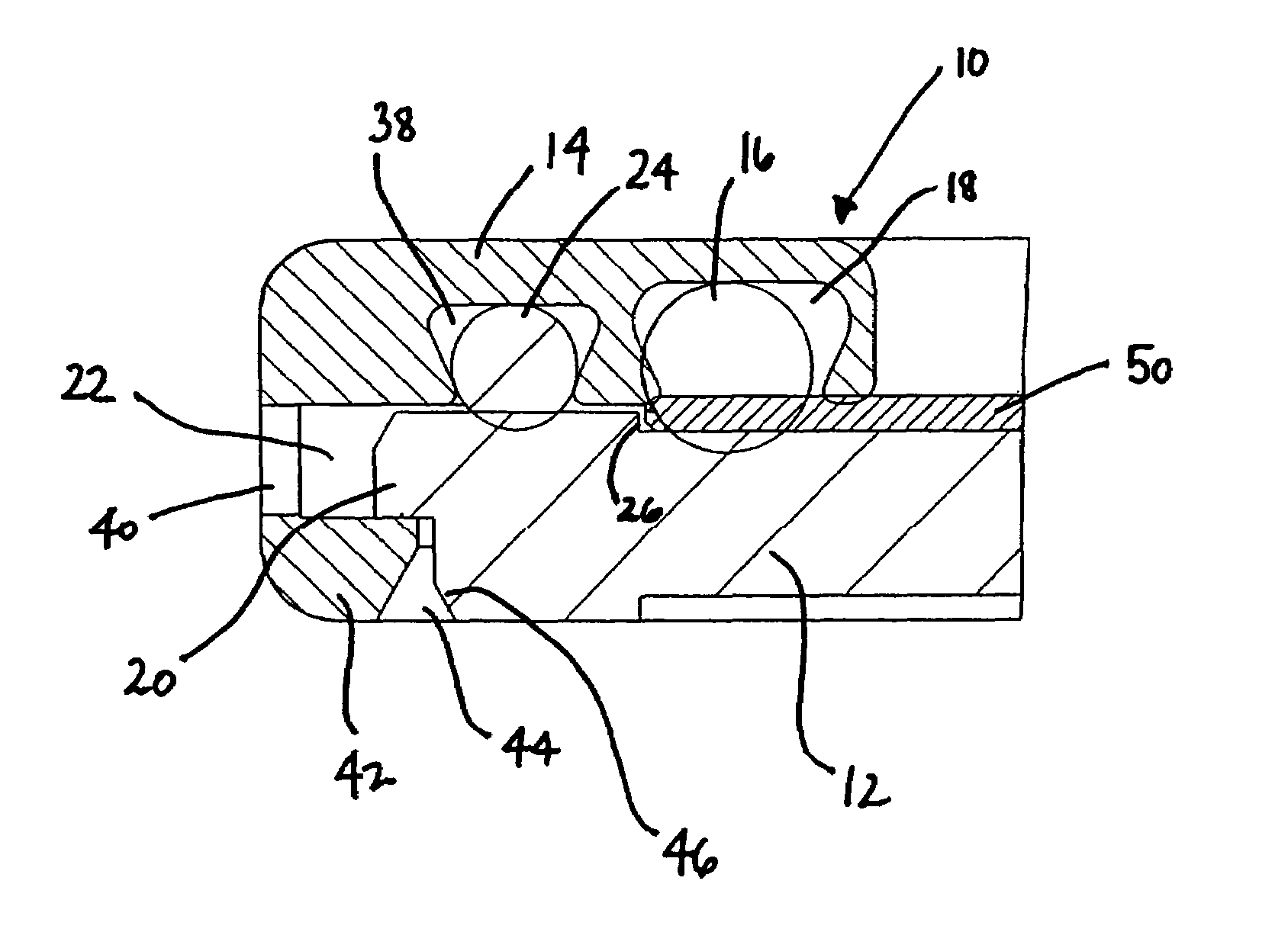

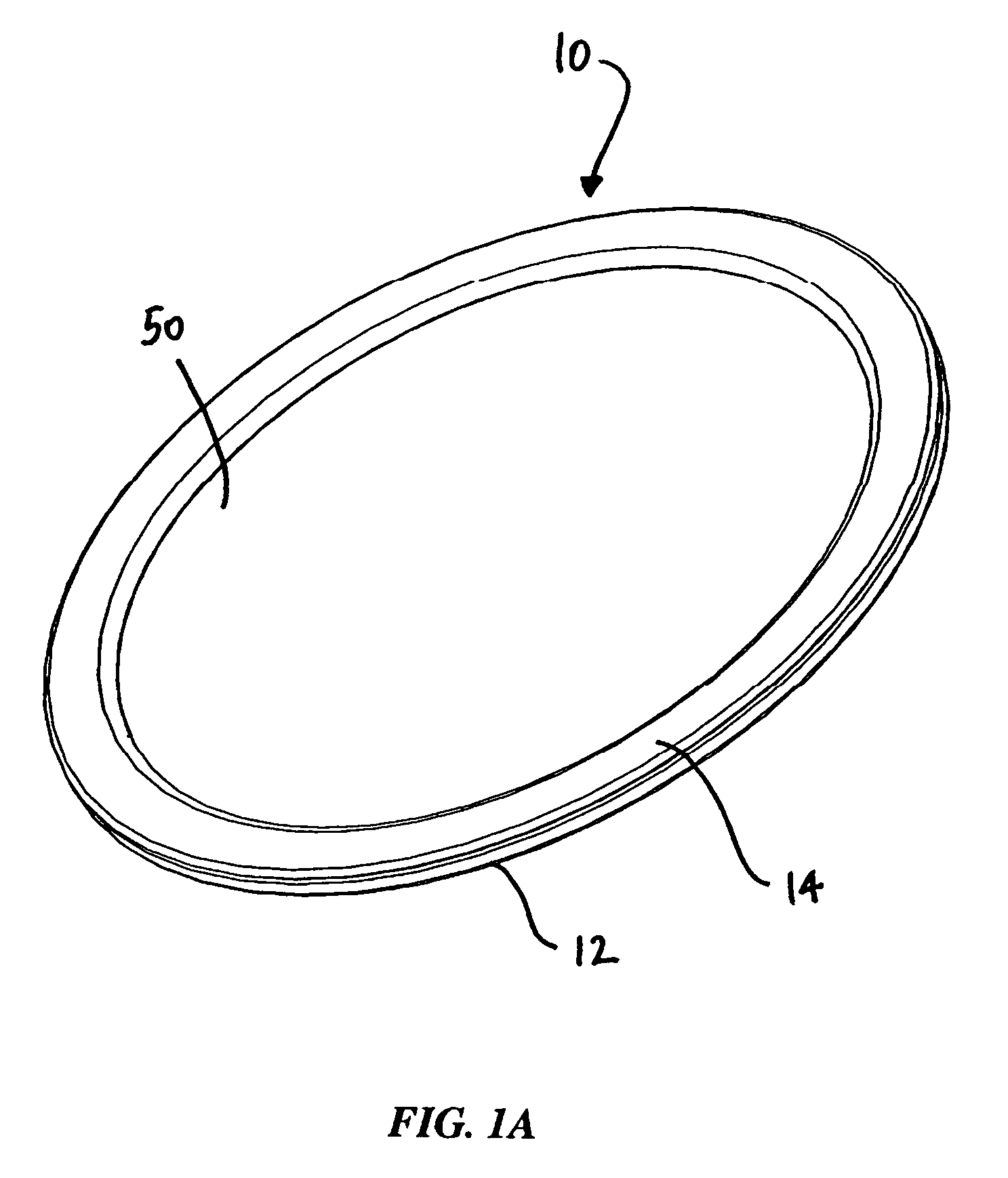

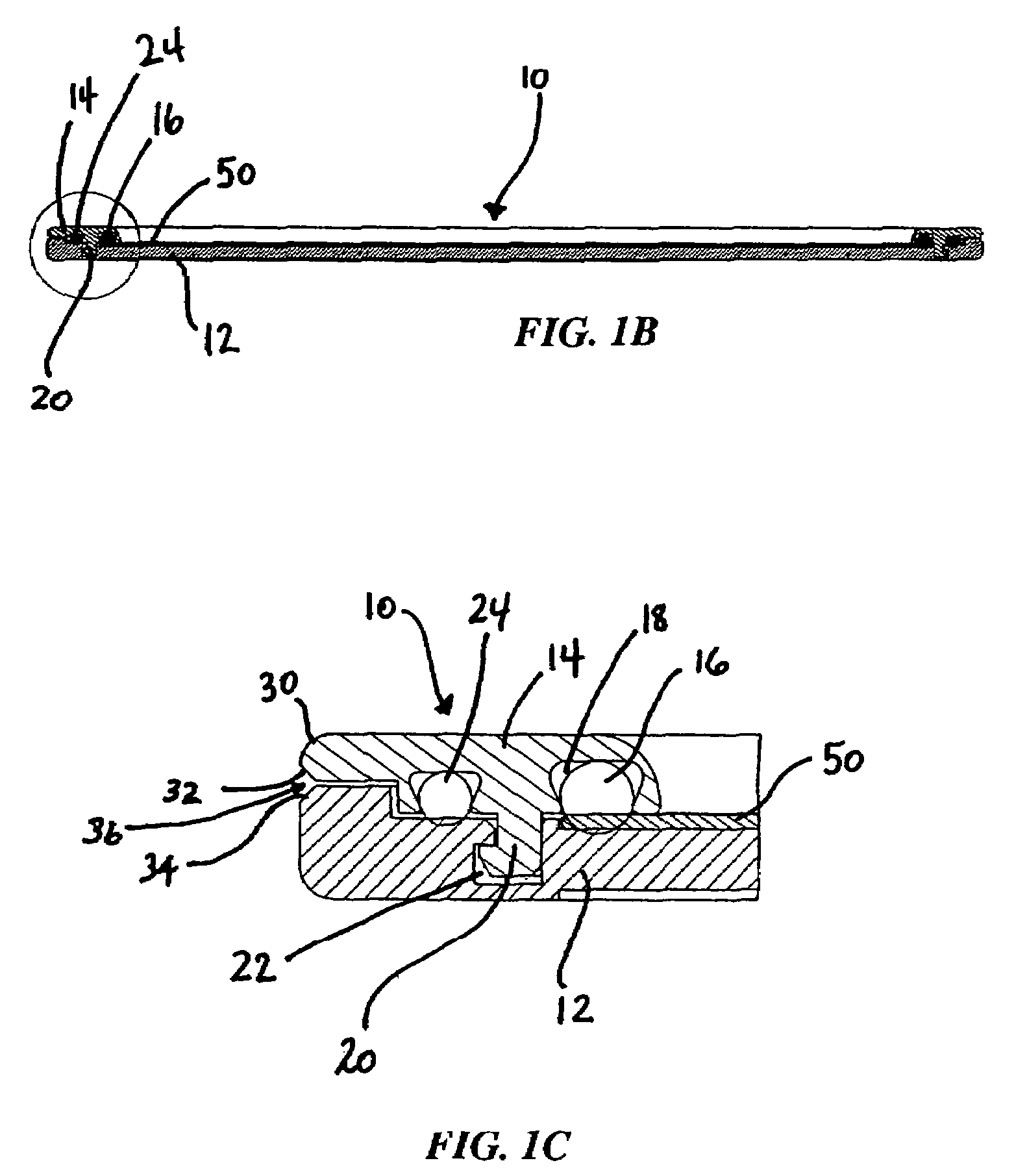

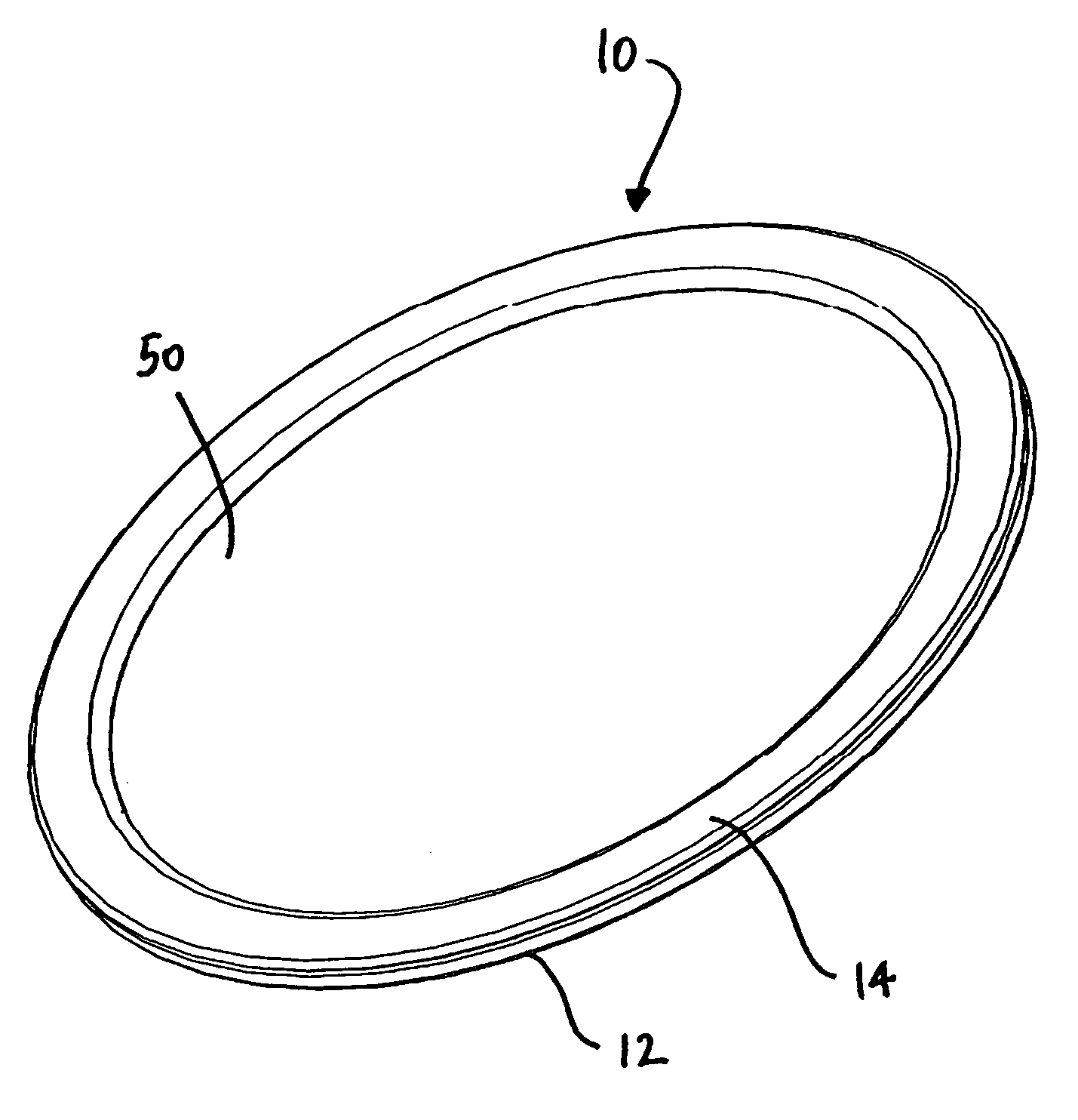

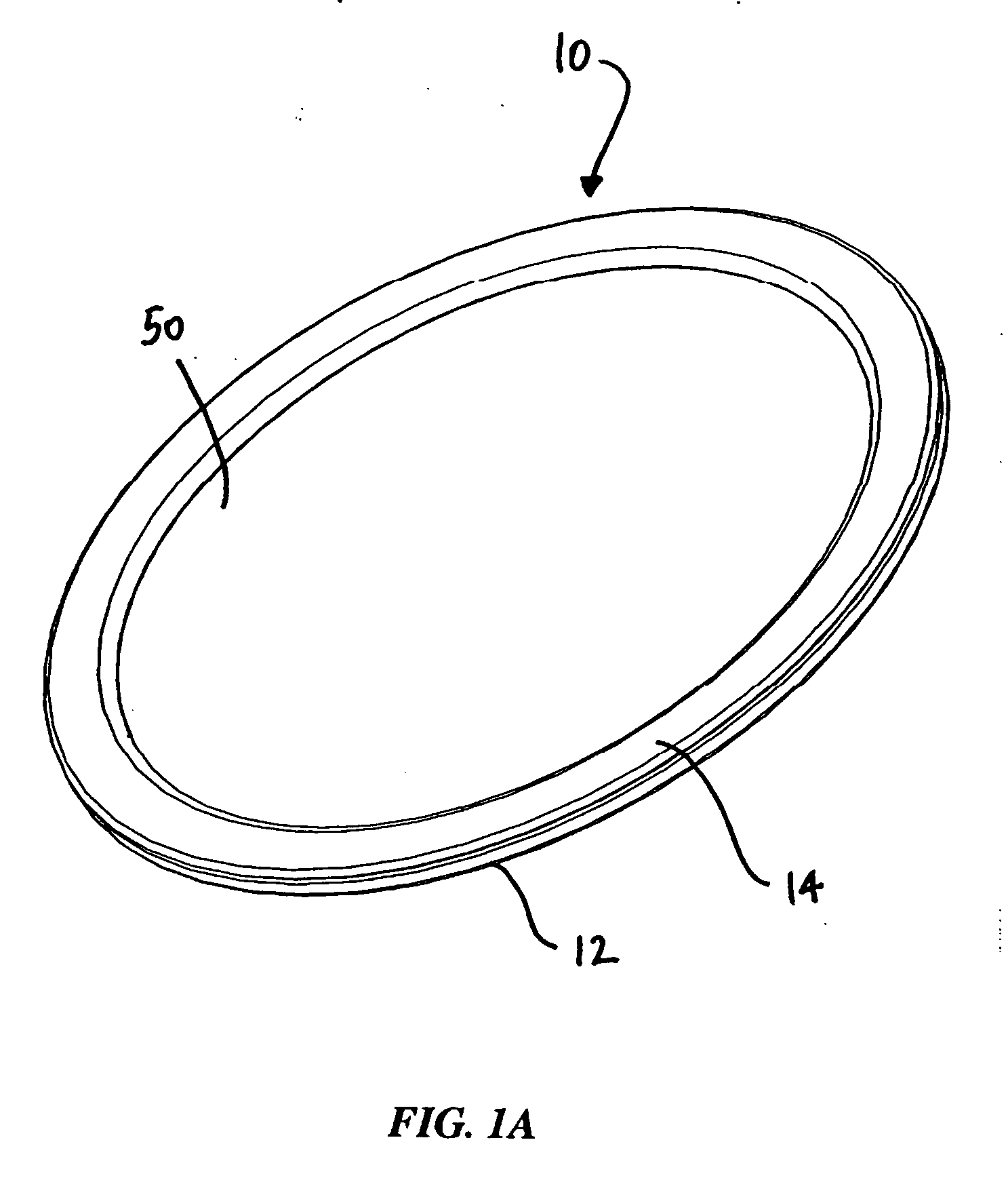

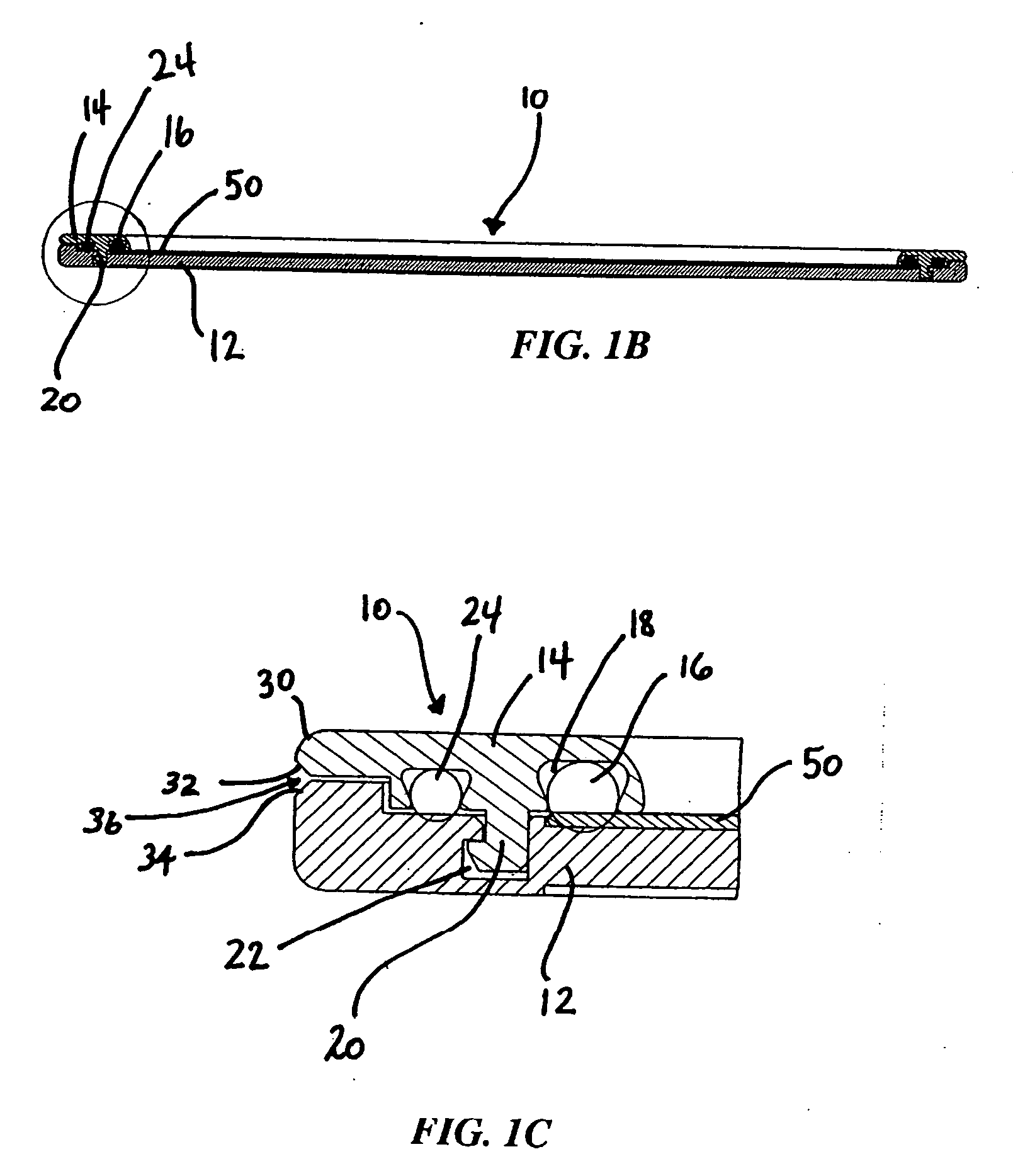

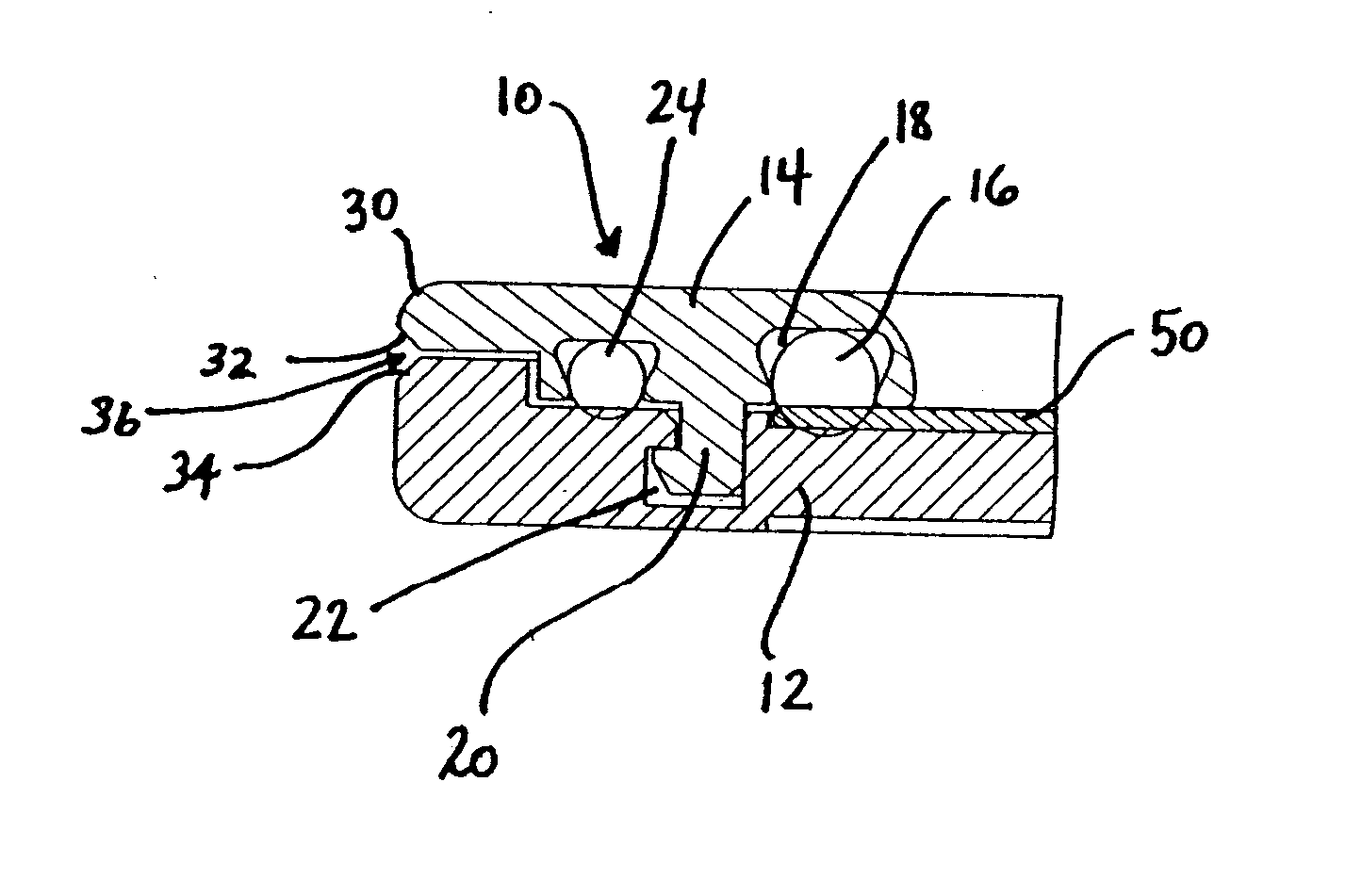

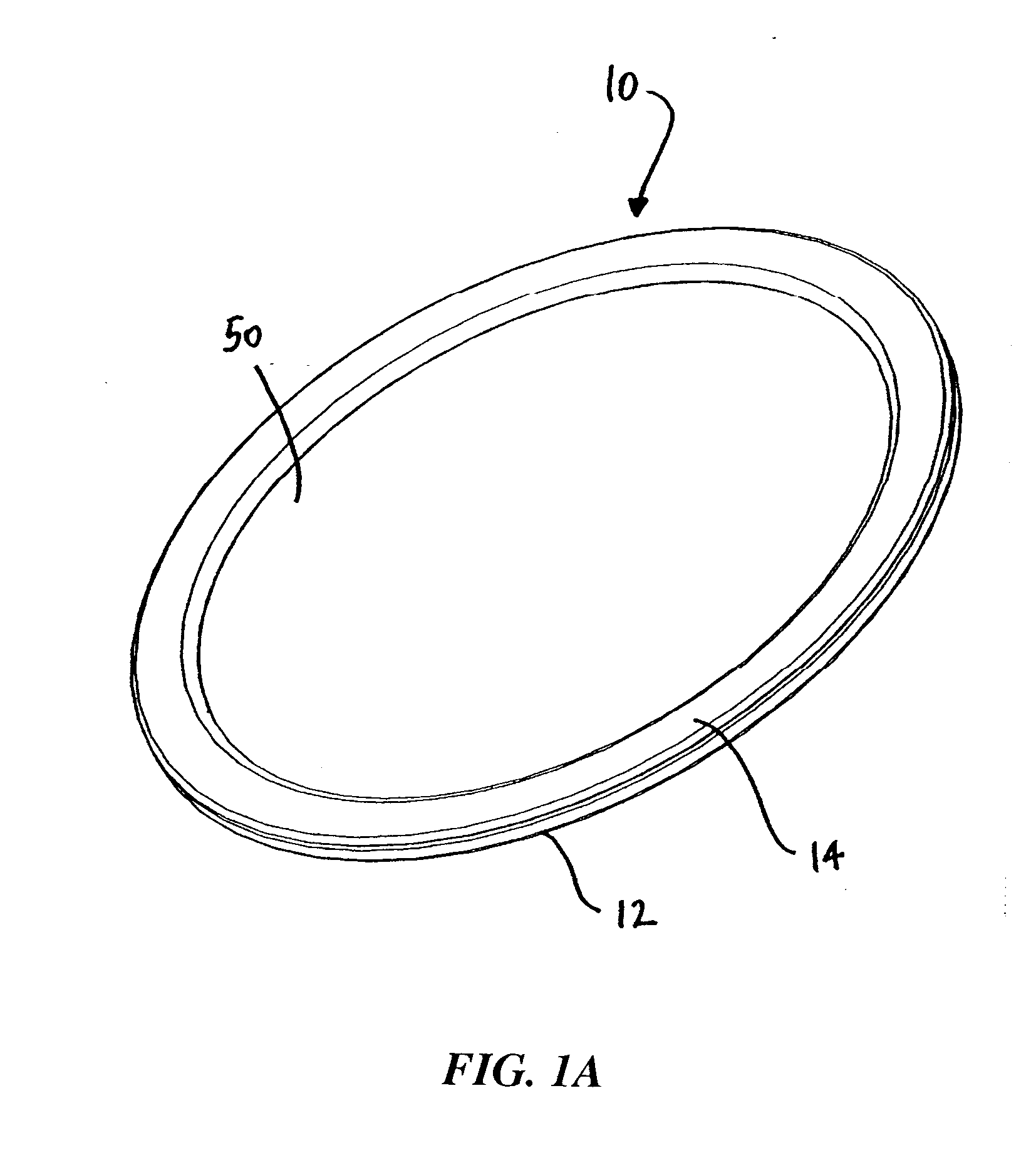

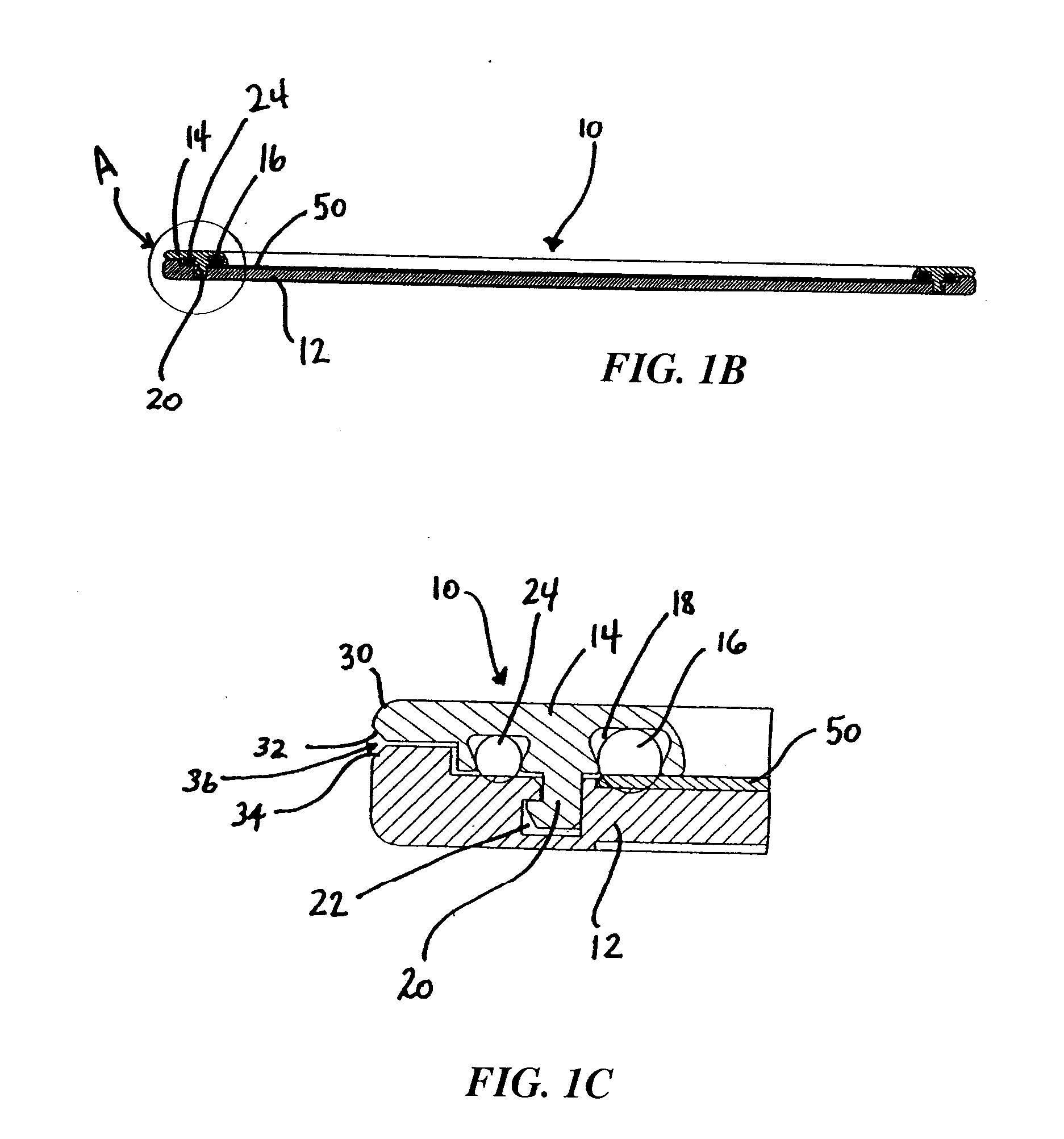

Process for thinning a semiconductor workpiece

InactiveUS7288489B2Avoid breakingSimple product structureDecorative surface effectsSemiconductor/solid-state device detailsSemiconductor materialsProcess efficiency

The present invention provides an apparatus and method for use in processing semiconductor workpieces. The new apparatus and method allows for the production of thinner workpieces that at the same time remain strong. Particularly, a chuck is provided that includes a body, a retainer removeably attached to the body and a seal forming member. When a workpiece is placed on the chuck body and the retainer is engaged to the body, a peripheral portion of the back side of the workpiece is covered by the retainer while an interior region of the back side of the workpiece is exposed. The exposed back side of the workpiece is then subjected to a wet chemical etching process to thin the workpiece and form a relatively thick rim comprised of semiconductor material at the periphery of the workpiece. The thick rim or hoop imparts strength to the otherwise fragile, thinned semiconductor workpiece. Semiconductor workpieces made according to the present invention offer an improved structure for handling thinned wafers in conventional automated equipment. This results in improved yields and improved process efficiency.

Owner:APPLIED MATERIALS INC

Semiconductor workpiece

InactiveUS7354649B2Avoid breakingSimple product structureSynthetic resin layered productsSemiconductor/solid-state device manufacturingSemiconductor materialsProcess efficiency

The present invention provides an apparatus and method for use in processing semiconductor workpieces. The new apparatus and method allows for the production of thinner workpieces that at the same time remain strong. Particularly, a chuck is provided that includes a body, a retainer removeably attached to the body and a seal forming member. When a workpiece is placed on the chuck body and the retainer is engaged to the body, a peripheral portion of the back side of the workpiece is covered by the retainer while an interior region of the back side of the workpiece is exposed. The exposed back side of the workpiece is then subjected to a wet chemical etching process to thin the workpiece and form a relatively thick rim comprised of semiconductor material at the periphery of the workpiece. The thick rim or hoop imparts strength to the otherwise fragile, thinned semiconductor workpiece. Semiconductor workpieces made according to the present invention offer an improved structure for handling thinned wafers in conventional automated equipment. This results in improved yields and improved process efficiency.

Owner:APPLIED MATERIALS INC

Semiconductor workpiece

InactiveUS20060040086A1Less susceptible to breakageImproved product structureSynthetic resin layered productsSemiconductor/solid-state device manufacturingCompound (substance)Engineering

The present invention provides an apparatus and method for use in processing semiconductor workpieces. The new apparatus and method allows for the production of thinner workpieces that at the same time remain strong. Particularly, a chuck is provided that includes a body, a retainer removeably attached to the body and a seal forming member. When a workpiece is placed on the chuck body and the retainer is engaged to the body, a peripheral portion of the back side of the workpiece is covered by the retainer while an interior region of the back side of the workpiece is exposed. The exposed back side of the workpiece is then subjected to a wet chemical etching process to thin the workpiece and form a relatively thick rim comprised of semiconductor material at the periphery of the workpiece. The thick rim or hoop imparts strength to the otherwise fragile, thinned semiconductor workpiece. Semiconductor workpieces made according to the present invention offer an improved structure for handling thinned wafers in conventional automated equipment. This results in improved yields and improved process efficiency.

Owner:APPLIED MATERIALS INC

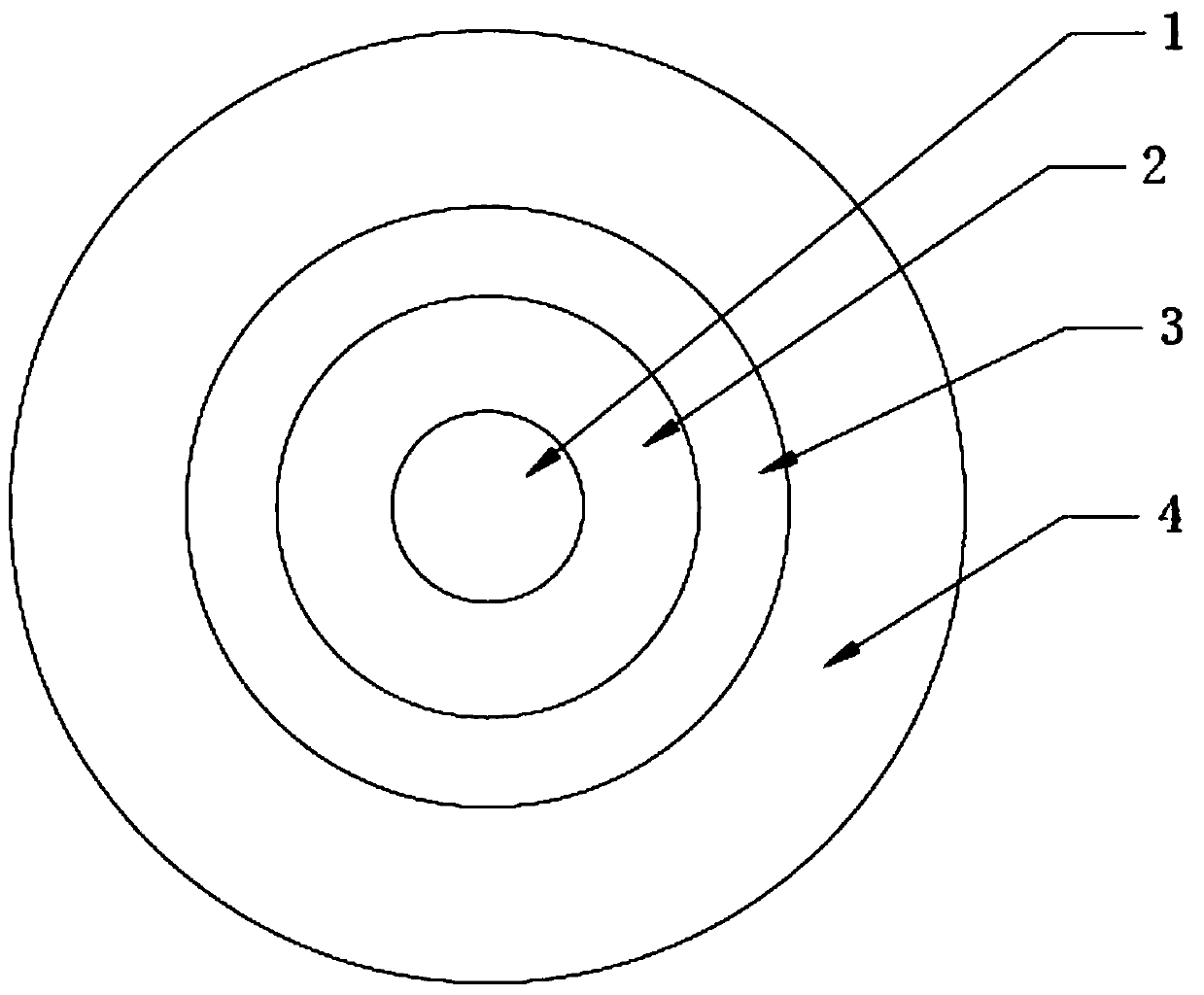

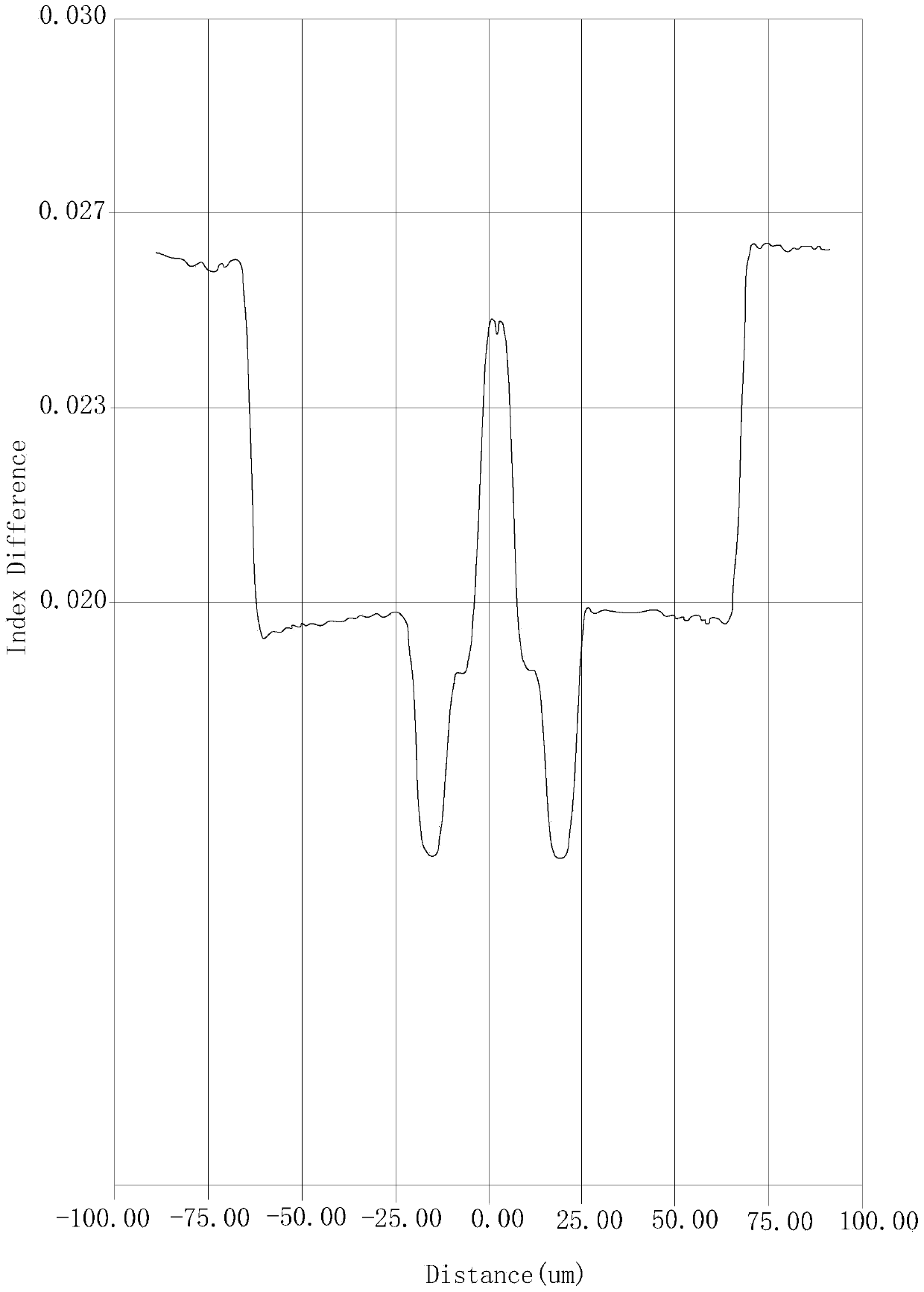

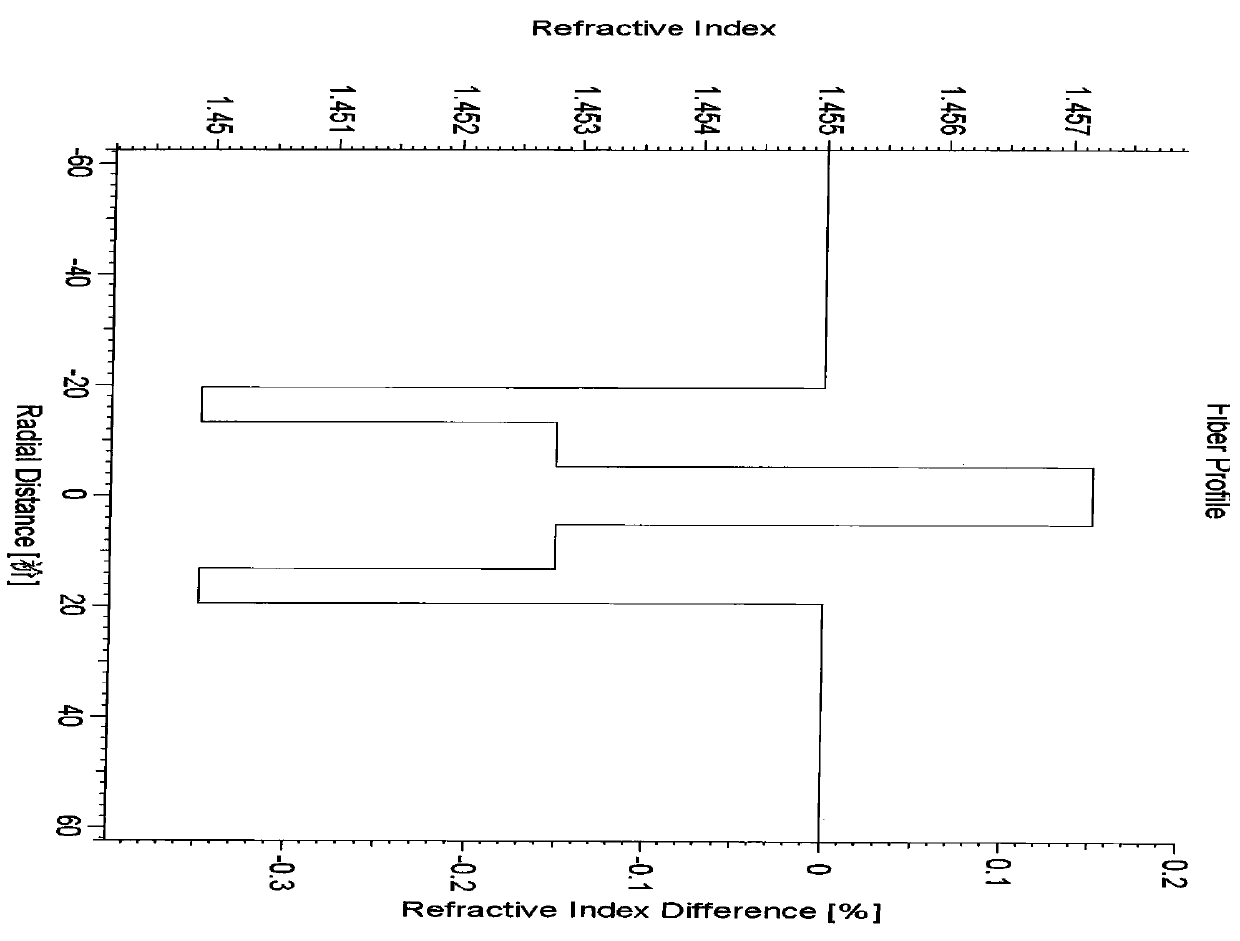

Optical fiber and manufacturing method thereof

InactiveCN104216045ASmall attenuationImprove flexibilityGlass making apparatusOptical fibre with multilayer core/claddingFiberRefractive index

The invention discloses an optical fiber and a manufacturing method thereof. The optical fiber comprises a fiber core layer and a wrapping layer; the fiber core layer is covered with the wrapping layer. The wrapping layer comprises an inner wrapping layer, a sunk wrapping layer and an outer wrapping layer in order from inside to outside. The optical fiber satisfies the following relations: delta 1 which is equal to n1-n0 is greater than -0.05% and less than -0.05%, delta 2 which is equal to n2-n0 is greater than -0.4% and less than -0.2%, delta 3 which is equal to n3-n0 is greater than -0.6% and less than -0.3%, and delta 4 which is equal to n4-n0 is greater than -0.3% and less than -0.1%, wherein n0 is the refractive index of pure quartz, n1 is the refractive index of the fiber core layer, n2 is the refractive index of the inner wrapping layer, n3 is the refractive index of sunk wrapping layer and n4 is the refractive index of the outer wrapping layer.

Owner:HENGTONG OPTICAL MATERIAL CO LTD

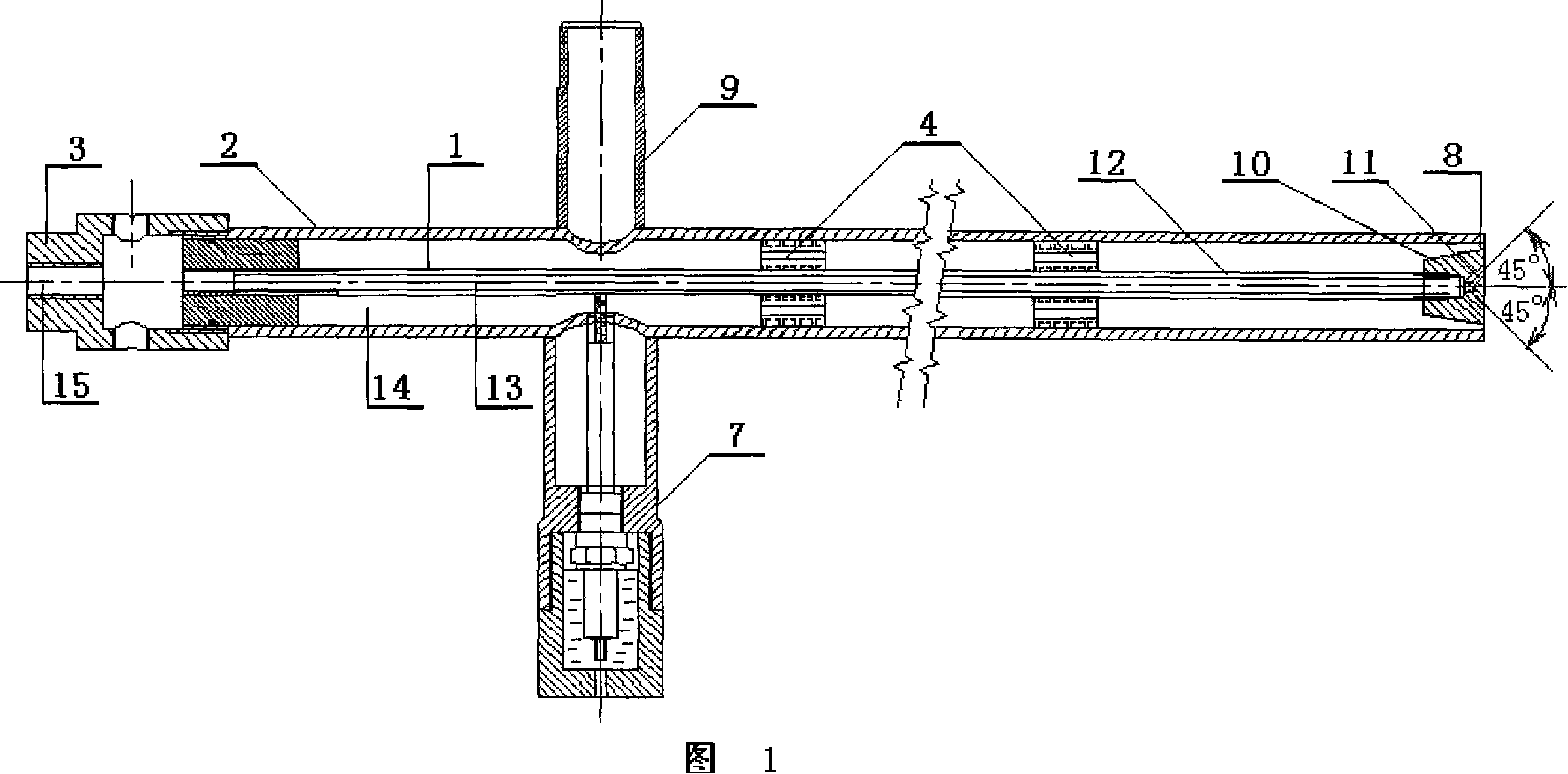

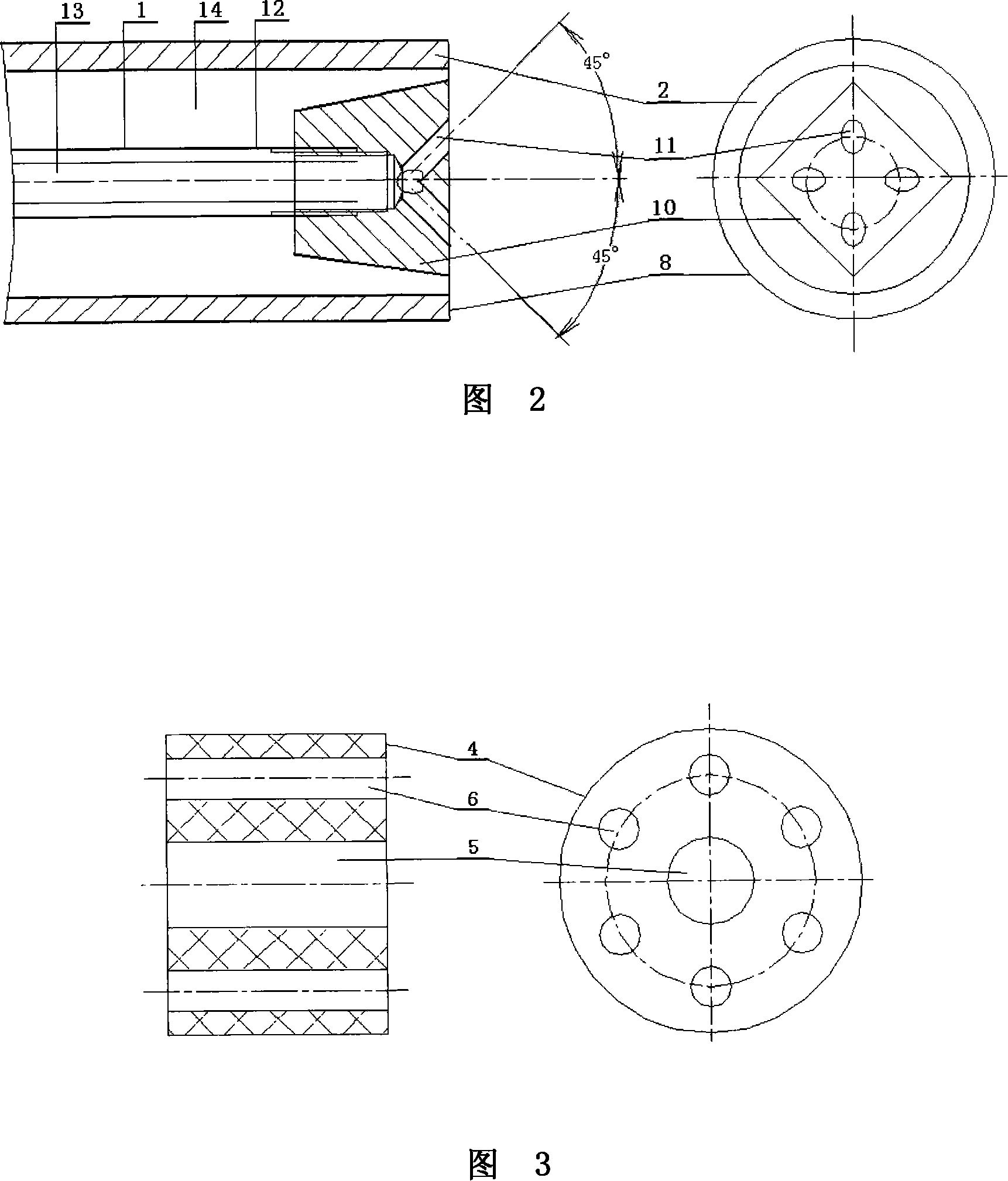

Ignition gun for industrial combustor

InactiveCN101109518AGuaranteed ignition success rateSimple product structureElectric spark ignitersPilot flame ignitersAirflowEngineering

The invention relates to an ignition gun for an industrial burner comprising a center pipe, an outer casing pipe, an igniting electrode, an insulation support and a transitional connector. On the insulation support, a center installation hole and an air flow hole are provided; the metallic pipe casing of the center pipe is connected with an igniting hi-pressure generator; the front end of the center pipe is provided with an igniting gun head nozzle block with a slant spraying hole; the metallic pipe wall of the outer casing pipe is provided with an entrance pipe for the combustion-supporting air; the center pipe is limited by the insulation support in the outer casing pipe. At operation, the metallic casing of the center pipe acts as a positive pole, the metallic casing of the outer casing pipe acts as a grounding negative pole, the inner of the center pipe is the channel for the gas fuel, and the space between the center pipe and the outer casing pipe is the channel for the combustion-supporting air; the gas fuel entered into the center pipe jets in a plurality of whiffs in dispersed way after passing the slant nozzles on the nozzle block; a discharging spark first fires one whiff and then the fired whiff ignites other whiffs to form a thick and long igniting torch. The invention is of simple and reasonable structure, works reliably and is of long service life, and is highly practical.

Owner:上海诺特飞博燃烧设备有限公司

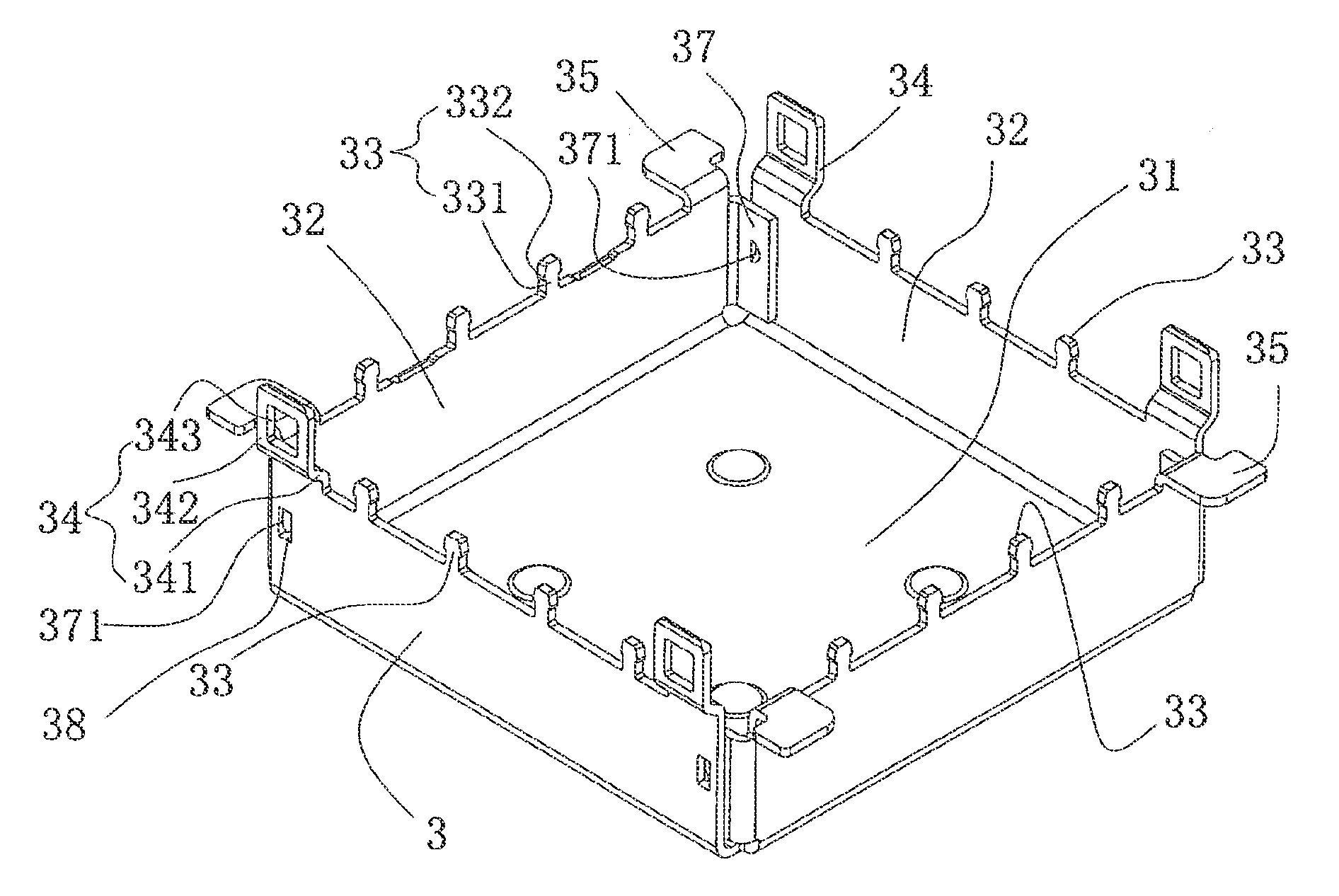

Camera socket connector

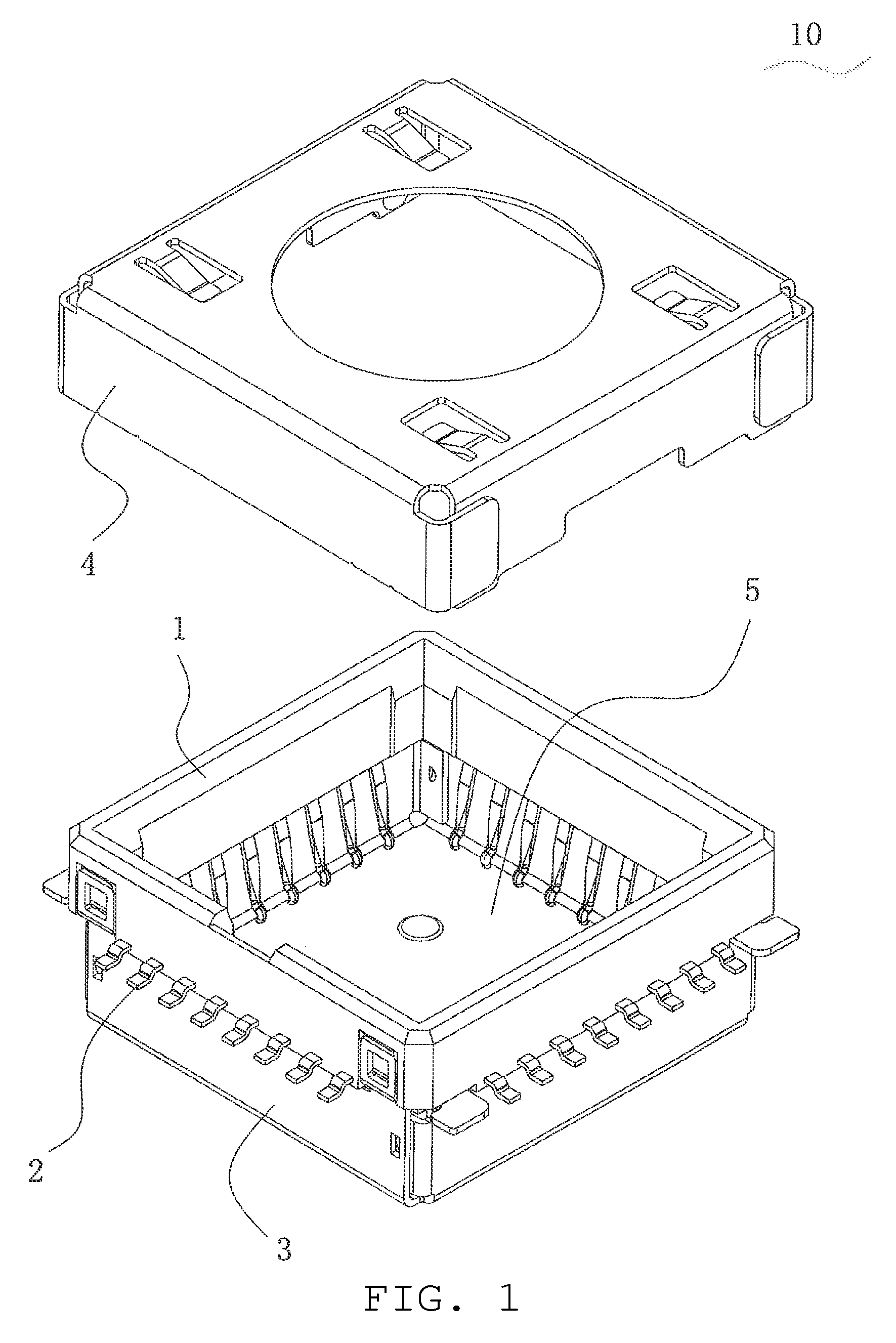

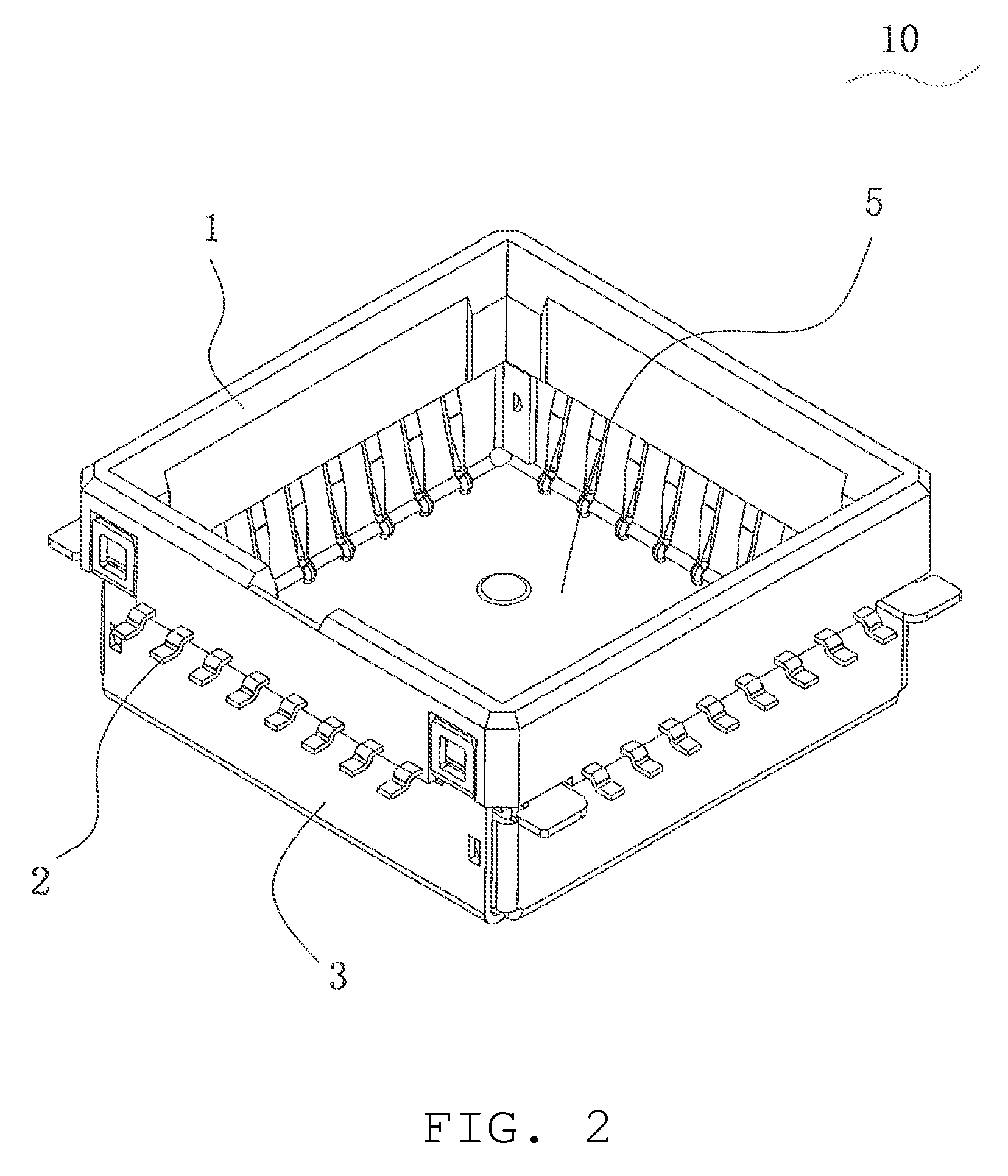

InactiveUS20120028501A1Reduce component countSimple product structureElectrically conductive connectionsCoupling device detailsEngineeringElectrical connector

An electrical connector suitable for correspondingly housing an electronic module, the electrical connector comprising an insulation body, a plurality of conductive terminals installed on the insulation body, and a shielding housing, wherein the insulation body is a square frame enclosed by four side walls, and the shielding housing is installed beneath the insulation body, comprising a bottom wall and four side walls extending upwards from the bottom wall, wherein the tops of the four side walls of the shielding housing are correspondingly joined to the bottom of the four side walls of the insulation body so as to jointly form an electronic module receiving space which opens upward, and wherein each of the conductive terminals comprises a docking part extending into the receiving space, a welded part extending out of the insulation body, and a fixed part fixed onto a side wall of the insulation body.

Owner:MOLEX INC

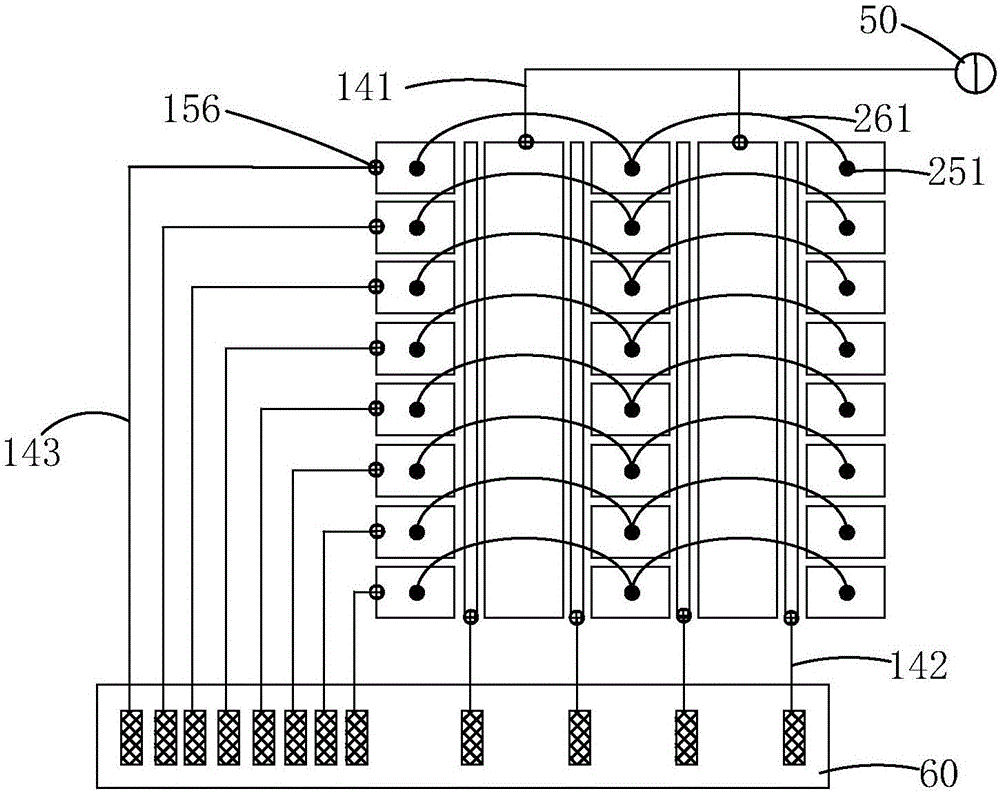

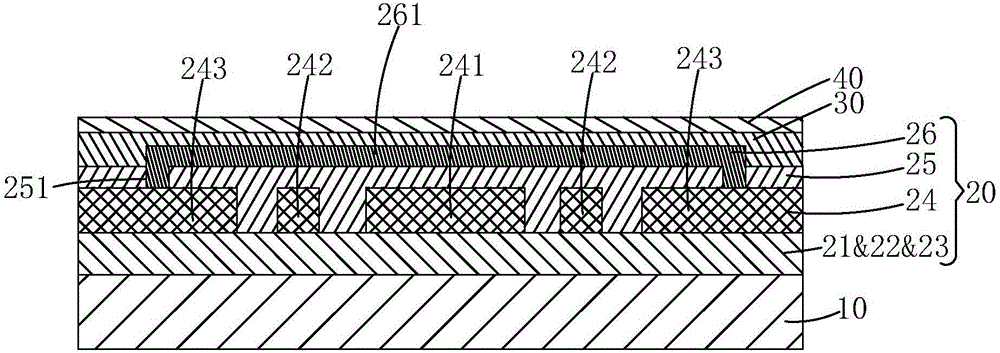

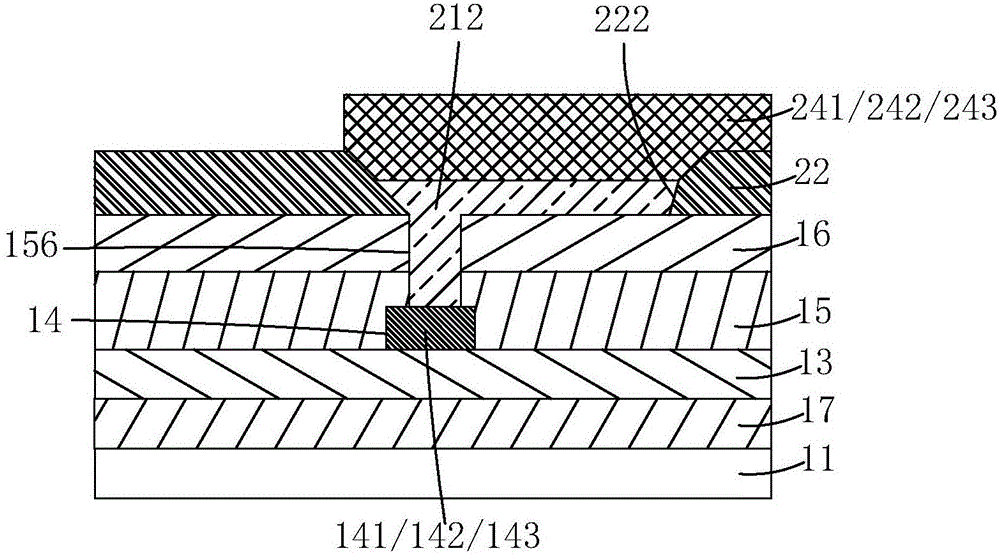

Embedded touch control AMOLED (Active-matrix Organic Light Emitting Diode) panel structure

ActiveCN107527938AAvoid signal shieldingSimple product structureSolid-state devicesInput/output processes for data processingFlexible displayControl layer

The invention provides an embedded touch control AMOLED (Active-matrix Organic Light Emitting Diode) panel structure. The embedded touch control AMOLED (Active-matrix Organic Light Emitting Diode) panel structure includes a TFT substrate and an OLED (Organic Light Emitting Diode) touch control layer disposed on the TFT substrate; the OLED touch control layer includes an anode conductive layer, a pixel definition layer, a light-emitting layer, a cathode conductive layer, an insulating layer and a bridging layer; the cathode conductive layer comprises a plurality of parallel cathode strips, a plurality of parallel touch control sensing lines and a plurality of arrayed touch control scanning electrode blocks; and the bridging layer includes bridging lines which are used for connecting each row of touch control scanning electrode blocks in series. According to the embedded touch control AMOLED (Active-matrix Organic Light Emitting Diode) panel structure of the invention, the cathode strips, the touch control sensing lines and the touch control scanning electrode blocks are arranged in the same layer in a split manner, and therefore, a signal shielding effect exerted on an embedded touch control sensor by an OLED cathode layer in a conventional AMOLED panel can be avoided, and therefore, a real embedded touch control technology is realized in the AMOLED panel, the structure of a product can be simplified, the thickness of the product can be greatly reduced, and a technical requirement for integrating ultra-thin display and the flexible display can be satisfied.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Biochemical long-acting soybean seed-coating agent

InactiveCN1806547AGuaranteed emergence rateIncrease productionBiocideAnimal repellantsMicroorganismCarbofuran

Disclosed is a biochemical long-acting soybean seed-coating agent which comprises the following constituents (by weight portions): auxiliary agent 10%, carbofuran 8%, carbendazol 12%, thiram 15%, water 54%, pix 0.115%, Paclobutrazol 0.015%, op emulsifying agent 0.5%, phosphoric acid 0.5%, phosphor and potassium solubilization bacteria 108 units / ml.

Owner:HEILONGJIANG BAYI AGRICULTURAL UNIVERSITY

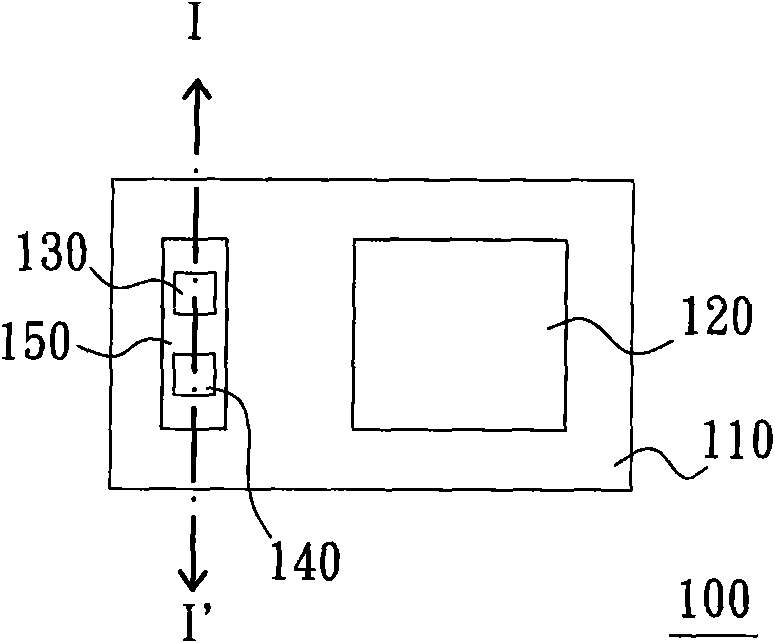

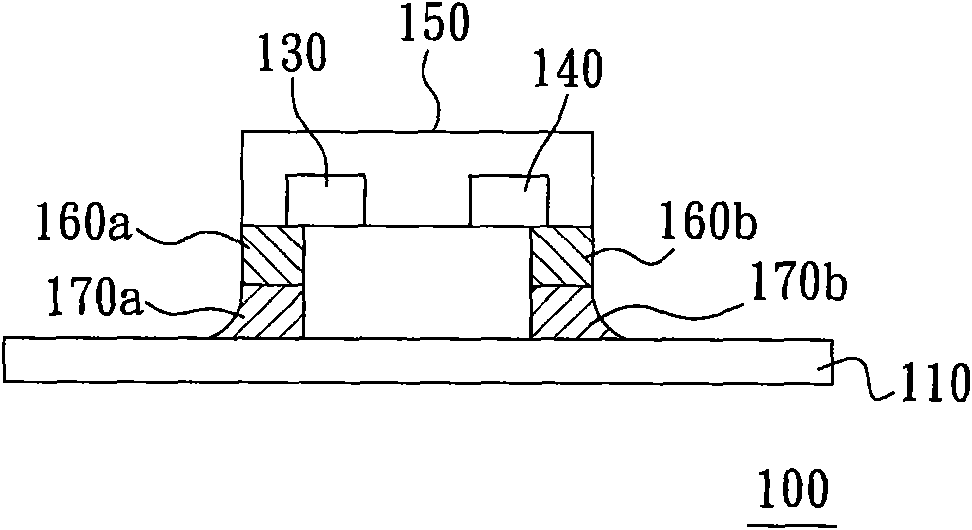

Sensing module

ActiveCN101667571AReduce manufacturing costReduce intensitySolid-state devicesSemiconductor devicesColloidEngineering

The invention relates to a sensing module, which comprises a carrying device, a sensor, a substrate and a plurality of wafers, wherein the carrying device is provided with a carrying surface and a back surface opposite to the carrying surface; the sensor is arranged on the carrying surface and is electrically connected to the carrying device; the substrate is arranged on the carrying device and iselectrically connected to the carrying surface; and the plurality of wafers are arranged on the substrate and are electrically connected to the substrate respectively. In the sensing module, becausethe wafers are arranged on the substrate, the wafers and the substrate are not needed to be modularized by a transparent encapsulating colloid so as to reduce the production cost of the sensing module. In the embodiment that one of the wafers is a luminescent wafer, because the wafer is not needed to be covered by the transparent encapsulating colloid, the intensity of light rays provided by the luminescent wafer is not weakened by the transparent encapsulating colloid, and thus, the light utilization efficiency of the sensing module can be improved.

Owner:MICROSOFT TECH LICENSING LLC

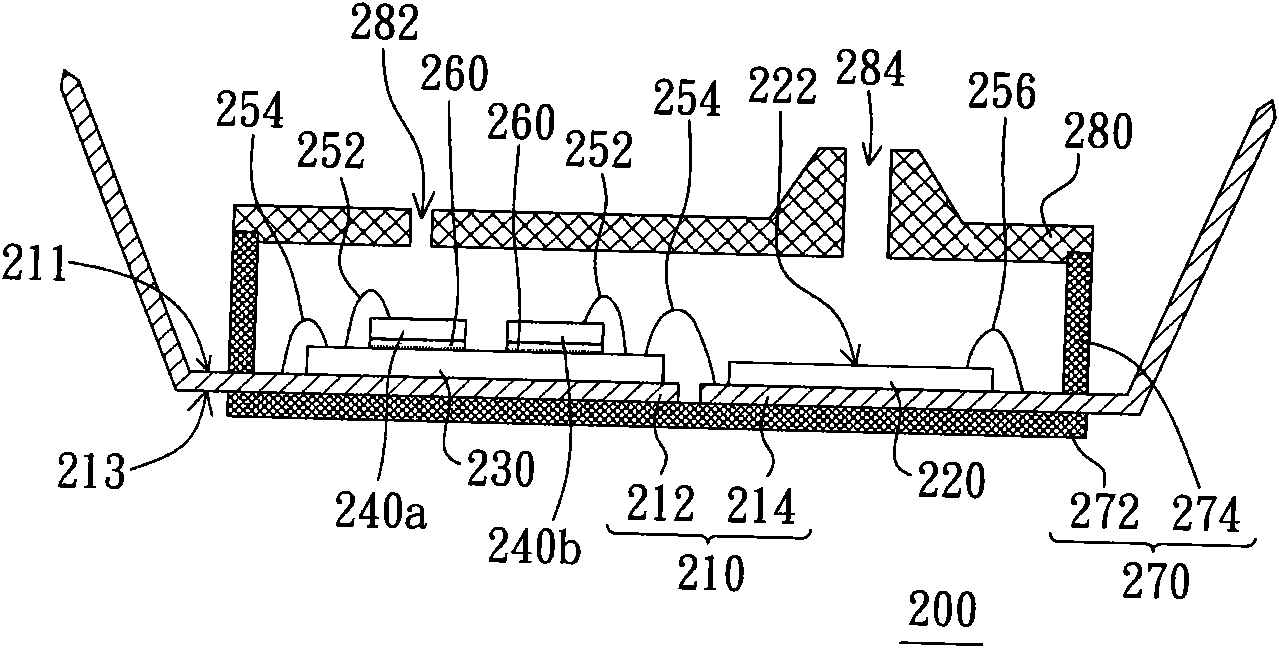

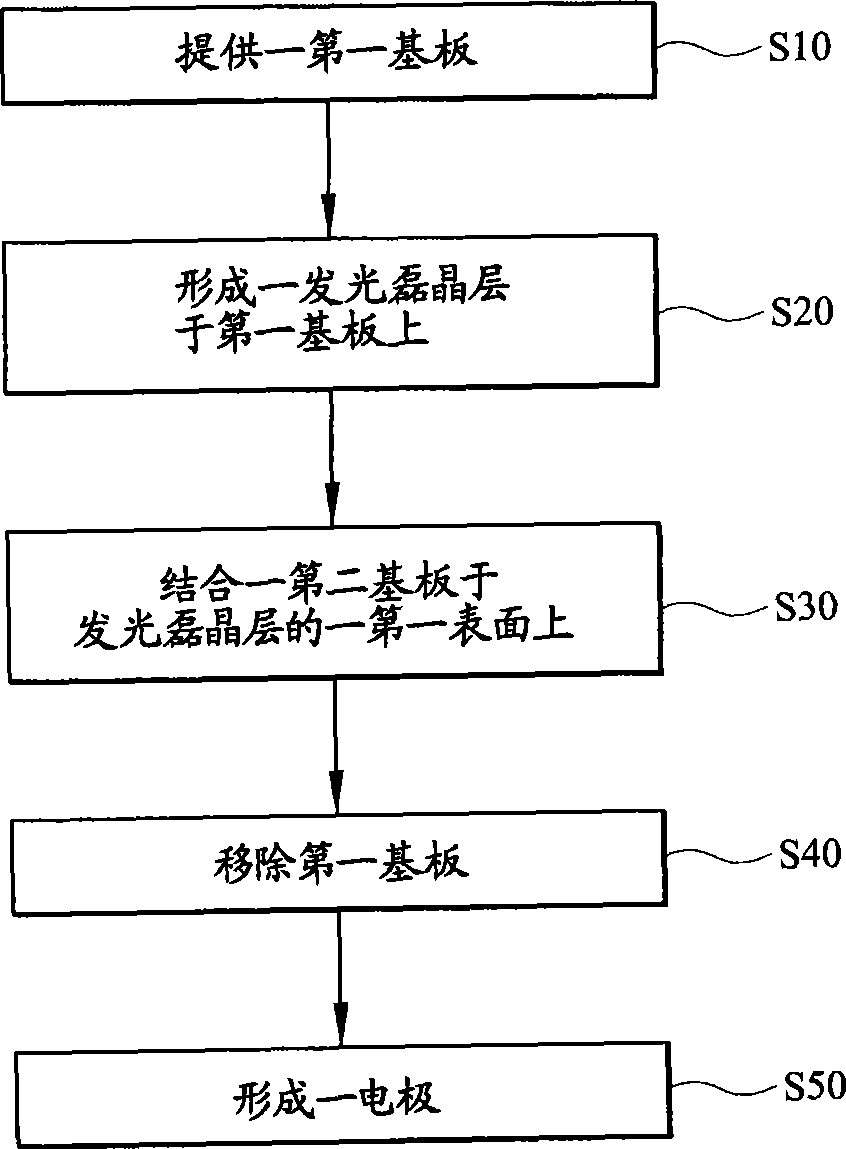

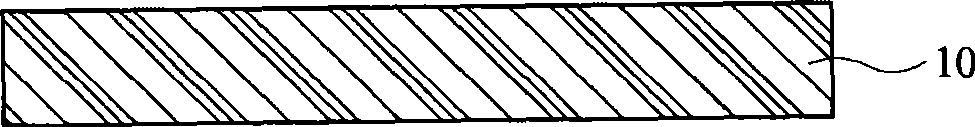

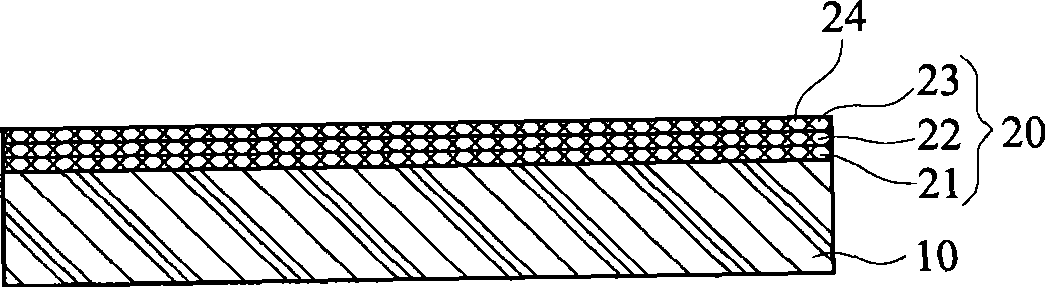

Method for manufacturing light-emitting dioxide having thermally and electrically conductive substrate and structure thereof

InactiveCN101521252AStable light qualityLow manufacturing costSemiconductor devicesThermal conductivityElectrically conductive

The invention relates to a method for manufacturing a light-emitting dioxide having a thermally and electrically conductive substrate and a structure thereof. The manufacturing method comprises the following steps of: providing a first substrate; forming a light emitting epitaxial layer on the first substrate; combining a second substrate on a first surface of the light emitting epitaxial layer; removing the first substrate; and forming an electrode. The structure of the light-emitting dioxide having the thermally and electrically conductive substrate comprises the second substrate, the light emitting epitaxial layer and the electrode. A used thermally conducive and insulating substrate material with high thermal conductivity allows the heat generated by the light-emitting dioxide during light emission to be discharged effectively to stabilize the quality of emitted light; and a used nonmetal thermally conductive and insulating substrate material results in the reduction of the manufacturing cost of the light-emitting dioxide.

Owner:钜亨电子材料元件有限公司

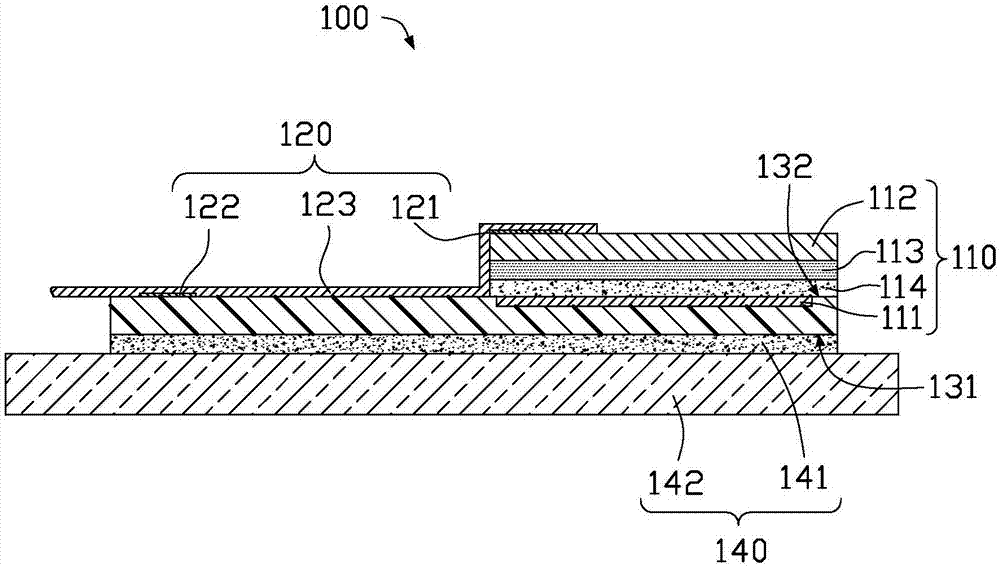

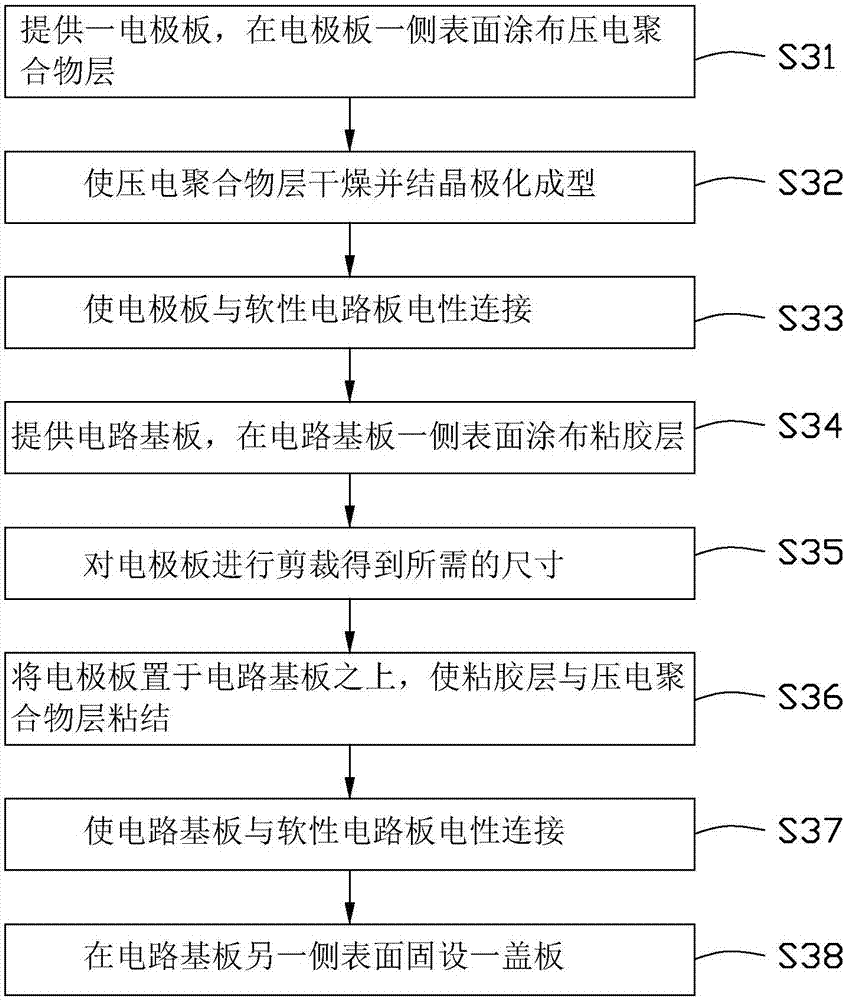

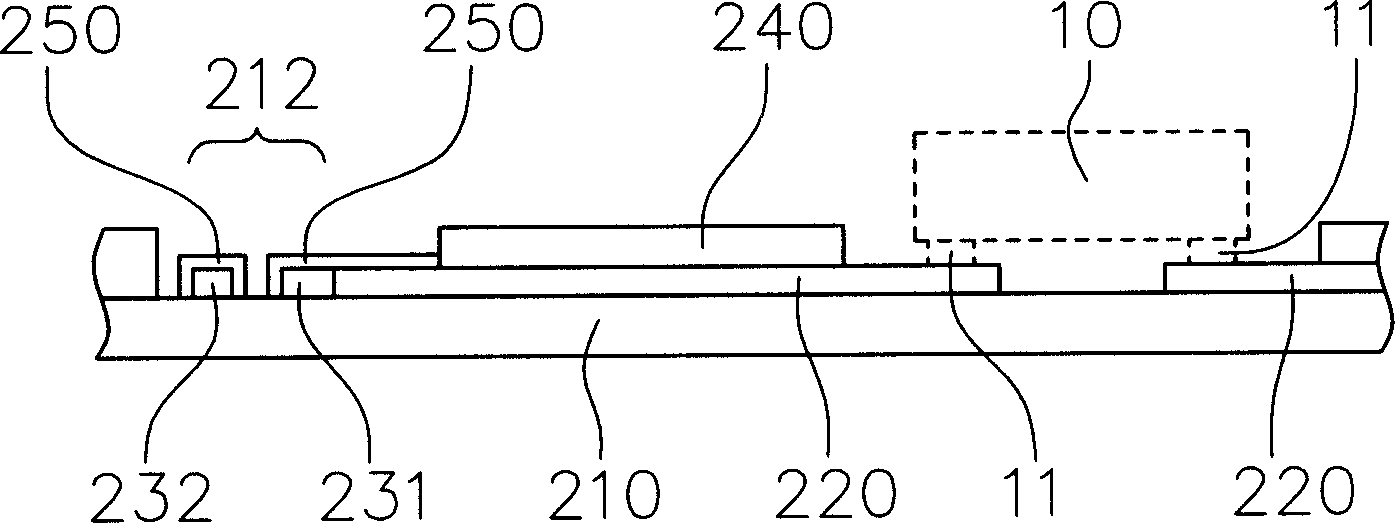

Sound wave type fingerprint recognizing device, manufacturing method thereof and electronic device using same

ActiveCN106874853ASensing results are accurateSimple product structureCharacter and pattern recognitionFingerprintElectricity

The invention provides a sound wave type fingerprint recognizing device which comprises a circuit board, an ultrasonic sensing unit and a signal transmission unit, wherein the ultrasonic sensing unit and the signal transmission unit are formed on the surface of the circuit board. The circuit board comprises a circuit. The ultrasonic sensing unit comprises a surface arranged on the circuit board, a first electrode, a piezoelectric polymer layer and a second electrode, wherein the first electrode, the piezoelectric polymer layer and the second electrode are electrically connected with the circuit. The signal transmission unit is electrically connected with the circuit and the second electrode to realize signal transmission. The second electrode directly contacts the piezoelectric polymer layer. The second electrode is the outer protective structure of the ultrasonic sensing unit. The invention further provides a manufacturing method of the sound wave type fingerprint recognizing device and an electronic device which uses the sound wave type fingerprint recognizing device.

Owner:INTERFACE TECH CHENGDU CO LTD +1

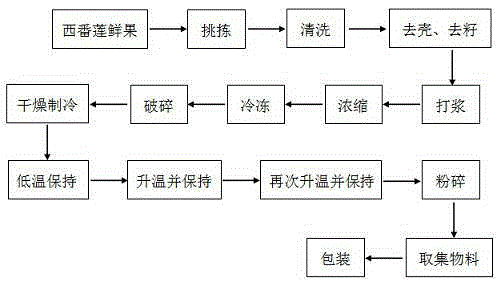

Technology for preparing fruit juice powder from passion fruits as raw materials

The invention discloses a technology for preparing fruit juice powder from passion fruits as raw materials. The technology comprises removing shells and seeds of selected and cleaned fresh passion fruits, beating the fresh passion fruits to obtain passion fruit raw pulp with soluble solid content of 10-12 brix degrees, total acid content of 3-5% and pH of 3.0+ / -0.5, carrying out freeze concentration on the passion fruit raw pulp to obtain thick paste with soluble solid content of 40-60 brix degrees, freezing the thick paste to a temperature of -50 to -60 DEG C, after freezing of all the thick paste, feeding the thick paste into a crusher, carrying out crushing so that particle diameter is less than 3mm, putting the crushed thick paste on a disc, putting the disc with the crushed thick paste into a drying tank, carrying out pressurization, carrying out freezing at a temperature of -29 to -23 DEG C, keeping the temperature for 3-6h, gradually heating the dried material to a temperature of 27 DEG C in 1-2h, carrying out heating again, keeping the temperature of 50-60 DEG C for several minutes, carrying out milling by a jet mill, collecting the aggregate which is fruit juice powder and carrying out packaging so that the passion fruit juice powder product with water content less than 4.5% is obtained. The juice powder retains nutrients, can be stored at a normal temperature for a long time, is free of dextrin and any antiseptic, has light weight, can be carried and transported easily, has a wide application range and is simple and convenient in use.

Owner:徐伟东

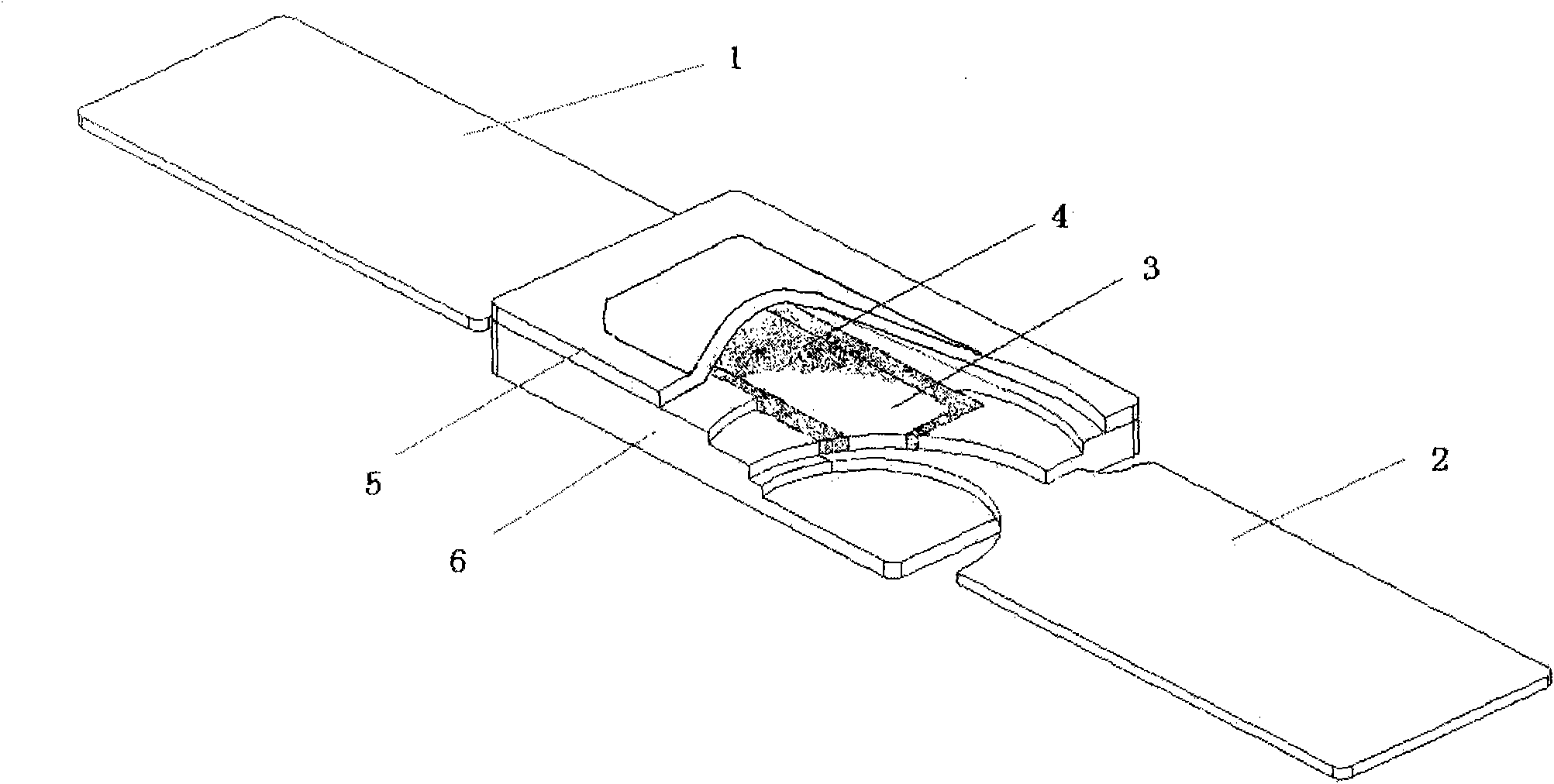

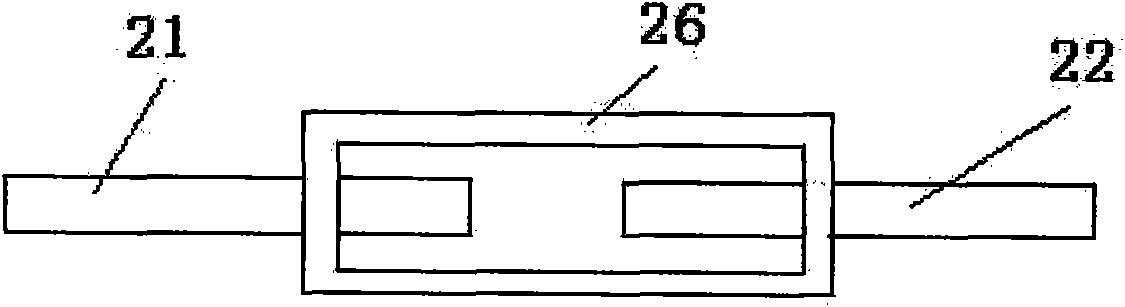

Temperature fuse and manufacturing method thereof

ActiveCN101859664AGood sealing performanceSimple product structureFuse device manufactureHeating/cooling contact switchesThermal cutoffClosed cavity

The invention discloses a flat temperature fuse and a manufacturing method thereof. The temperature fuse comprises two ribbon-like metal electrodes and a closed cavity, wherein the two ribbon-like metal electrodes are linearly arranged, a space is arranged between the opposite ends of the two metal electrodes, and the space is provided with a fusible alloy wire; the fusible alloy wire connects the two ribbon-like metal electrodes; the joints of the fusible alloy wire and the two ribbon-like metal electrodes are packaged in the closed cavity; and the closed cavity comprises a box body and a cover plate. The temperature fuse has the advantages of simple structure, favorable tightness, simple manufacturing technique and high production efficiency.

Owner:上海神沃电子有限公司

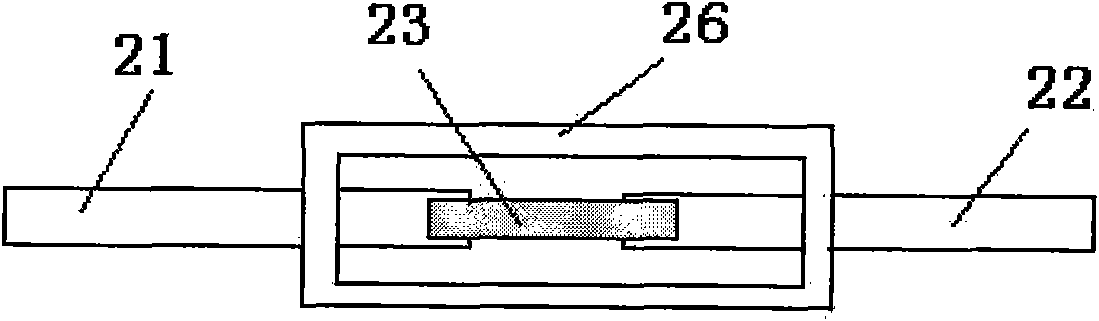

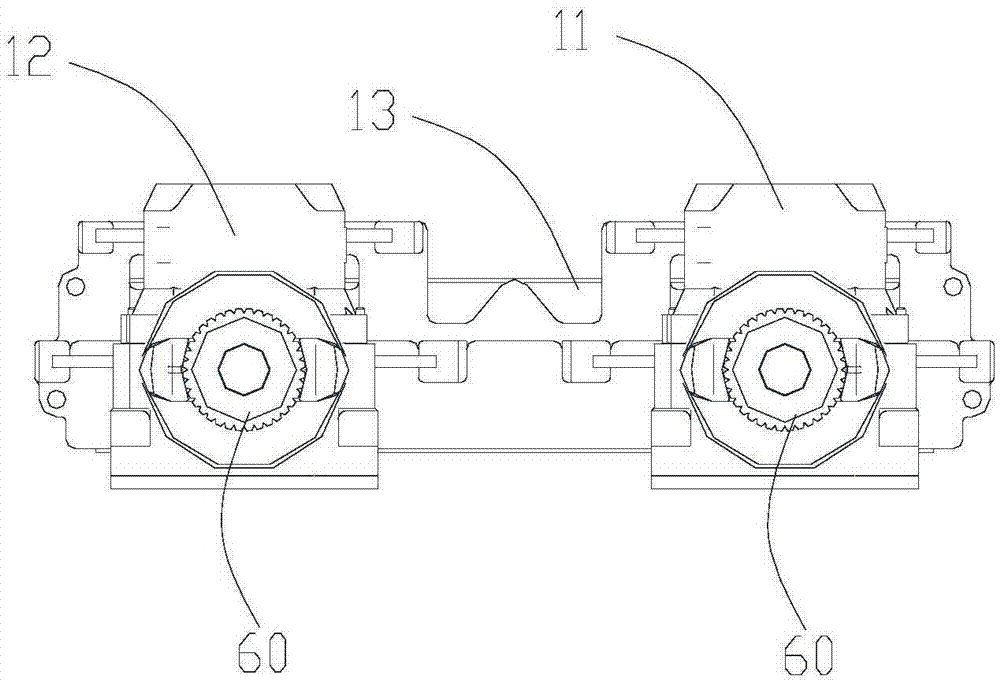

Head-mounted display

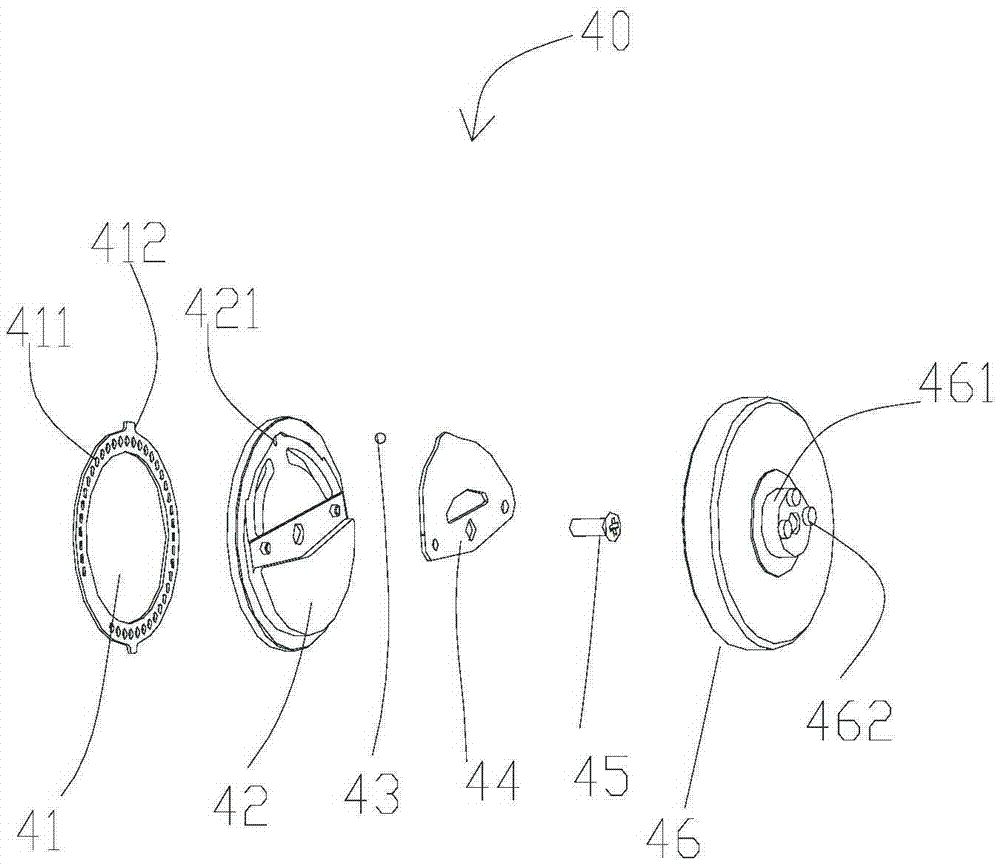

ActiveCN106873155AEasy to operateSimple product structurePlanar/plate-like light guidesSteroscopic systemsPupillary distanceDisplay device

The invention relates to a head-mounted display. The display comprises a main body framework. The main body framework is provided with left and right display screens and left and right eye lenses which are correspondingly arranged with the left and right display screens. The main body framework is provided with a diopter and pupillary distance adjusting mechanism used for simultaneously adjusting a distance between a single side display screen and the eye lenses and adjusting a distance between the two eye lenses. The diopter and pupillary distance adjusting mechanism comprises a driving component and a rotary knob component. The diopter and pupillary distance adjusting mechanism adopts rotation and slide operation of the same rotary knob component to realize diopter and pupillary distance adjusting of the head-mounted display respectively. Through rotating the rotary knob component, the diopter of the head-mounted display can be adjusted, and through sliding the rotary knob component, a pupillary distance of the head-mounted display can be adjusted. Operation is easy, a product structure is simplified, a product size of the head-mounted display is compact, weight is light and usage is comfortable and convenient.

Owner:SHENZHEN NED OPTICS CO LTD

Liquid transparency apparatus, system and network

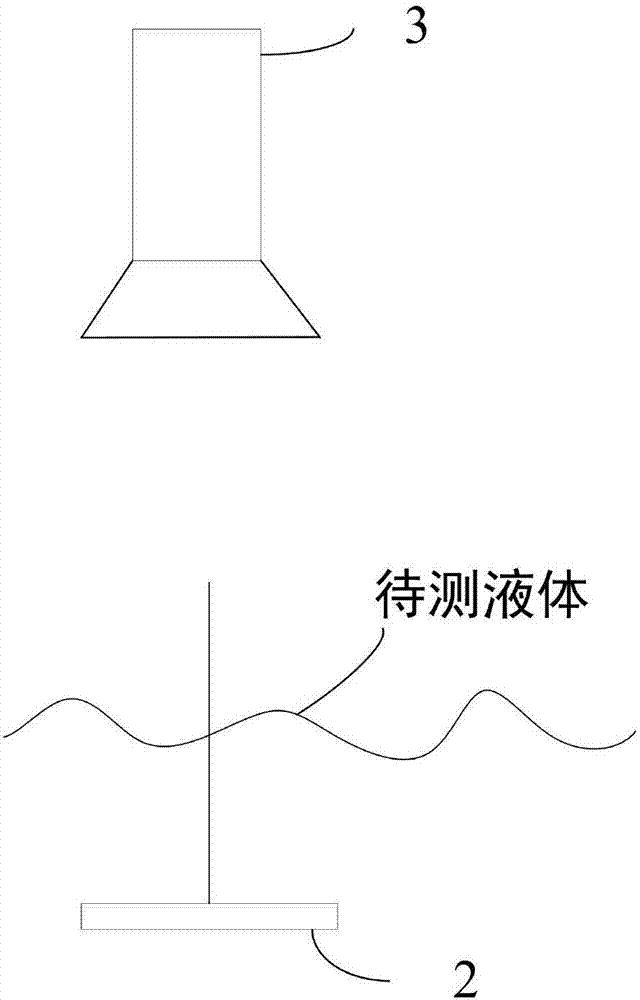

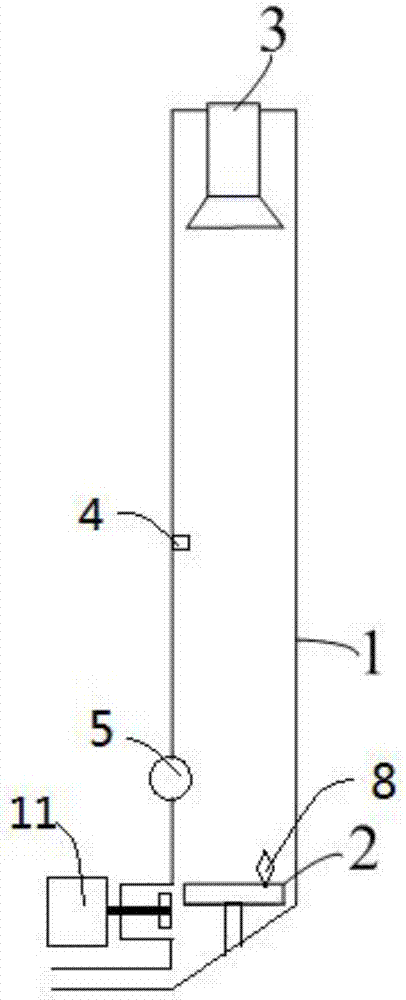

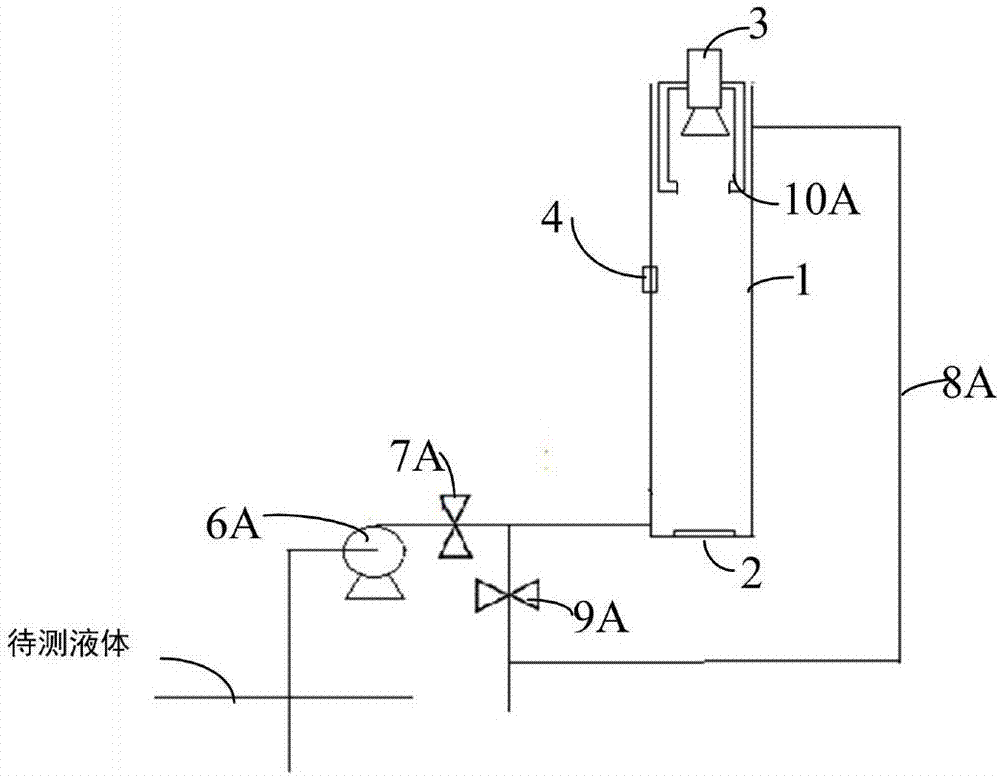

InactiveCN107084931ASimple product structureStable performanceColor/spectral properties measurementsLight sourceEngineering

The invention discloses a liquid transparency apparatus, a system and a network. The liquid transparency apparatus comprises an identification picture layer used for detection, an acquisition device (3) used for acquiring the signal of the identification picture layer, a measuring barrel (1) used for holding a to-be-measured sample, a liquid sensor (4) used for detecting the position of liquid, a light source (5) used for providing light, an optical detection device (8) used for detecting light intensity and a stirring device (11) used for preventing suspended solids in a sample from settlement. The liquid transparency apparatus provided by the invention can realize continuous automatic detection of liquid transparency, reduce influence of settlement of suspended solids in the sample on determination, is not affected by the eyesight of determination personnel and external light, accurately deliver the measured value of transparency and improves the work efficiency of detection personnel.

Owner:薛永富

Apparatus for use in thinning a semiconductor workpiece

InactiveUS20060220329A1Avoid breakingSimple product structureSleeve/socket jointsTurning machine accessoriesSemiconductor materialsCompound (substance)

The present invention provides an apparatus and method for use in processing semiconductor workpieces. The new apparatus and method allows for the production of thinner workpieces that at the same time remain strong. Particularly, a chuck is provided that includes a body, a retainer removeably attached to the body and a seal forming member. When a workpiece is placed on the chuck body and the retainer is engaged to the body, a peripheral portion of the back side of the workpiece is covered by the retainer while an interior region of the back side of the workpiece is exposed. The exposed back side of the workpiece is then subjected to a wet chemical etching process to thin the workpiece and form a relatively thick rim comprised of semiconductor material at the periphery of the workpiece. The thick rim or hoop imparts strength to the otherwise fragile, thinned semiconductor workpiece. Semiconductor workpieces made according to the present invention offer an improved structure for handling thinned wafers in conventional automated equipment. This results in improved yields and improved process efficiency.

Owner:SEMITOOL INC

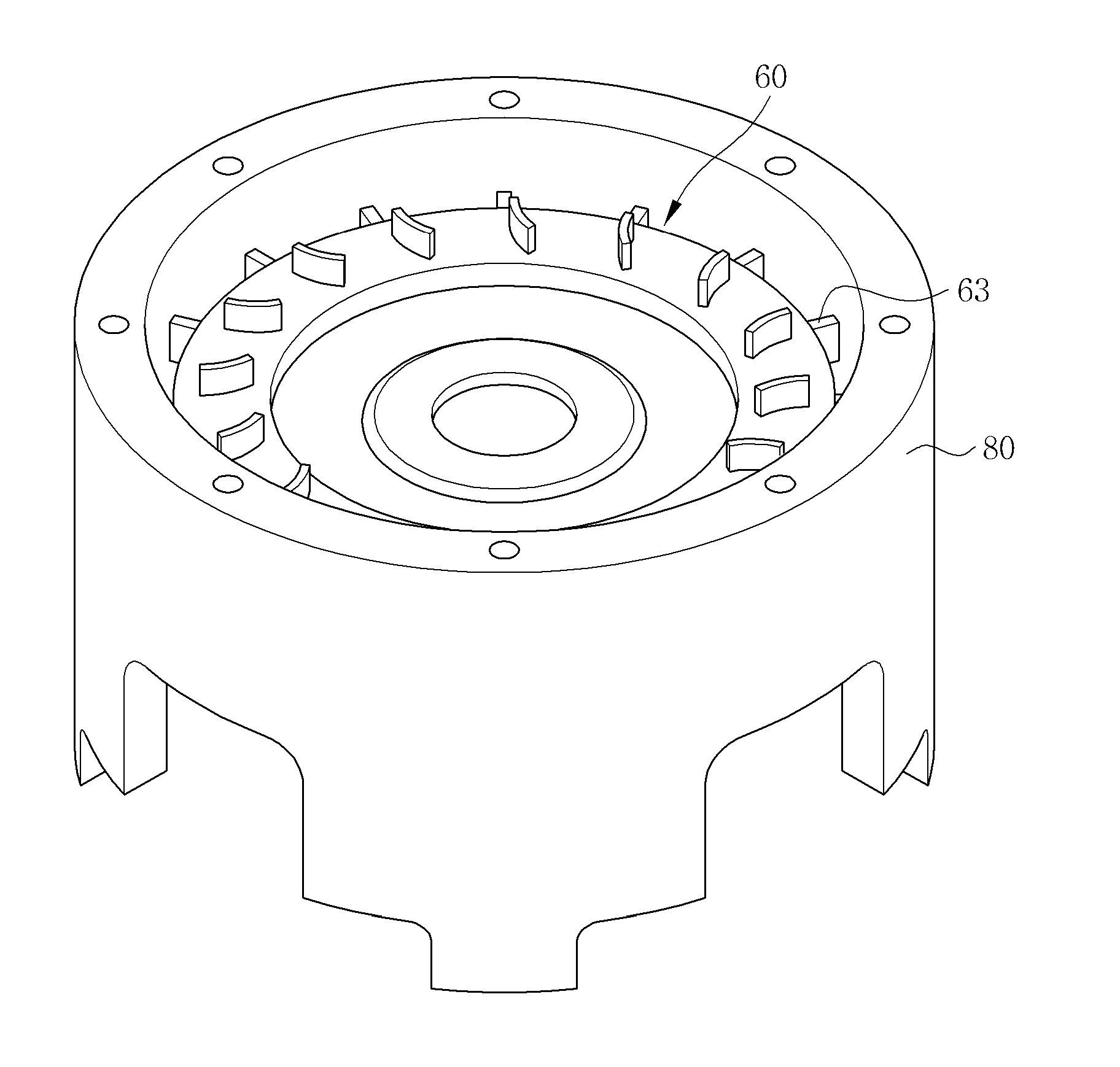

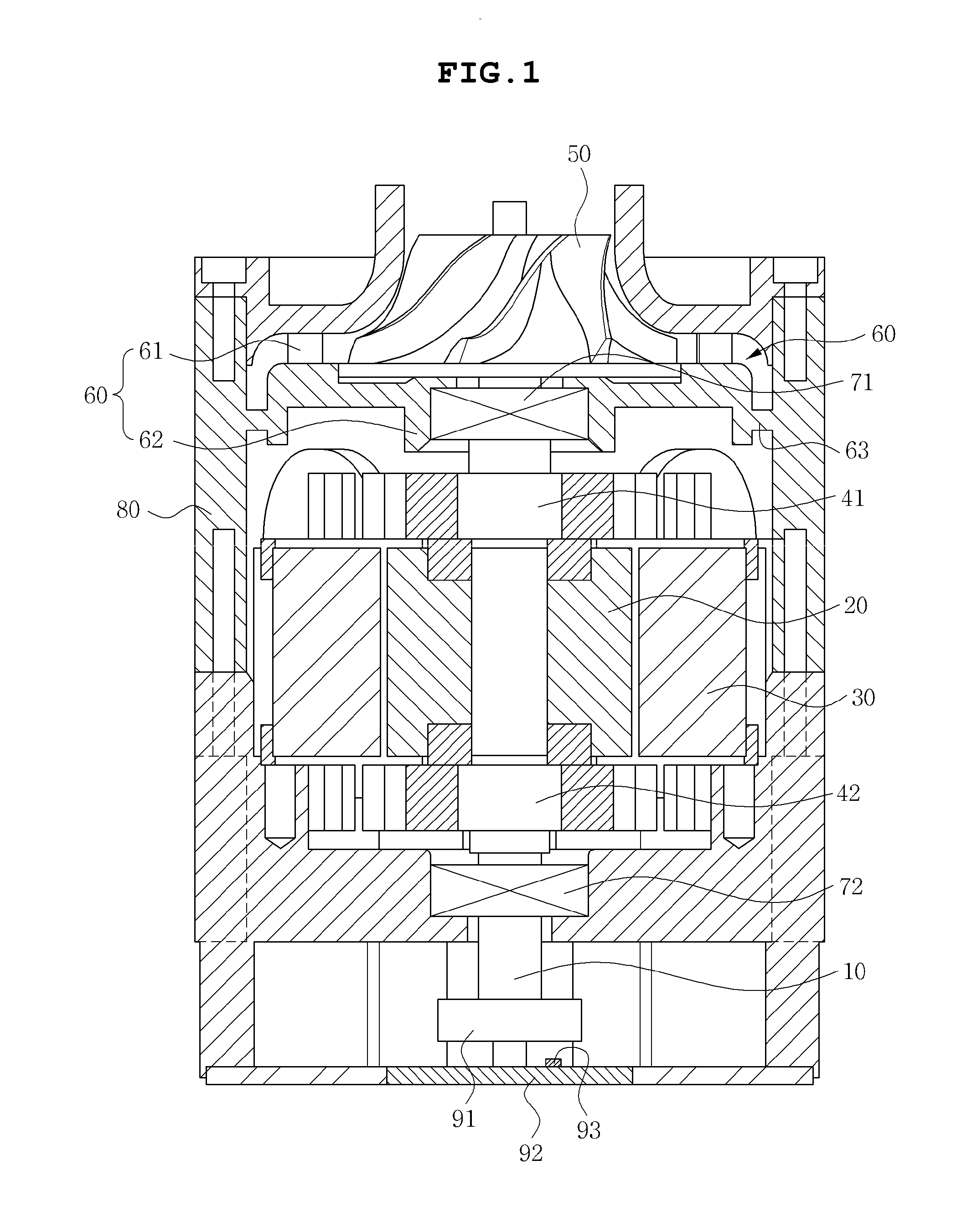

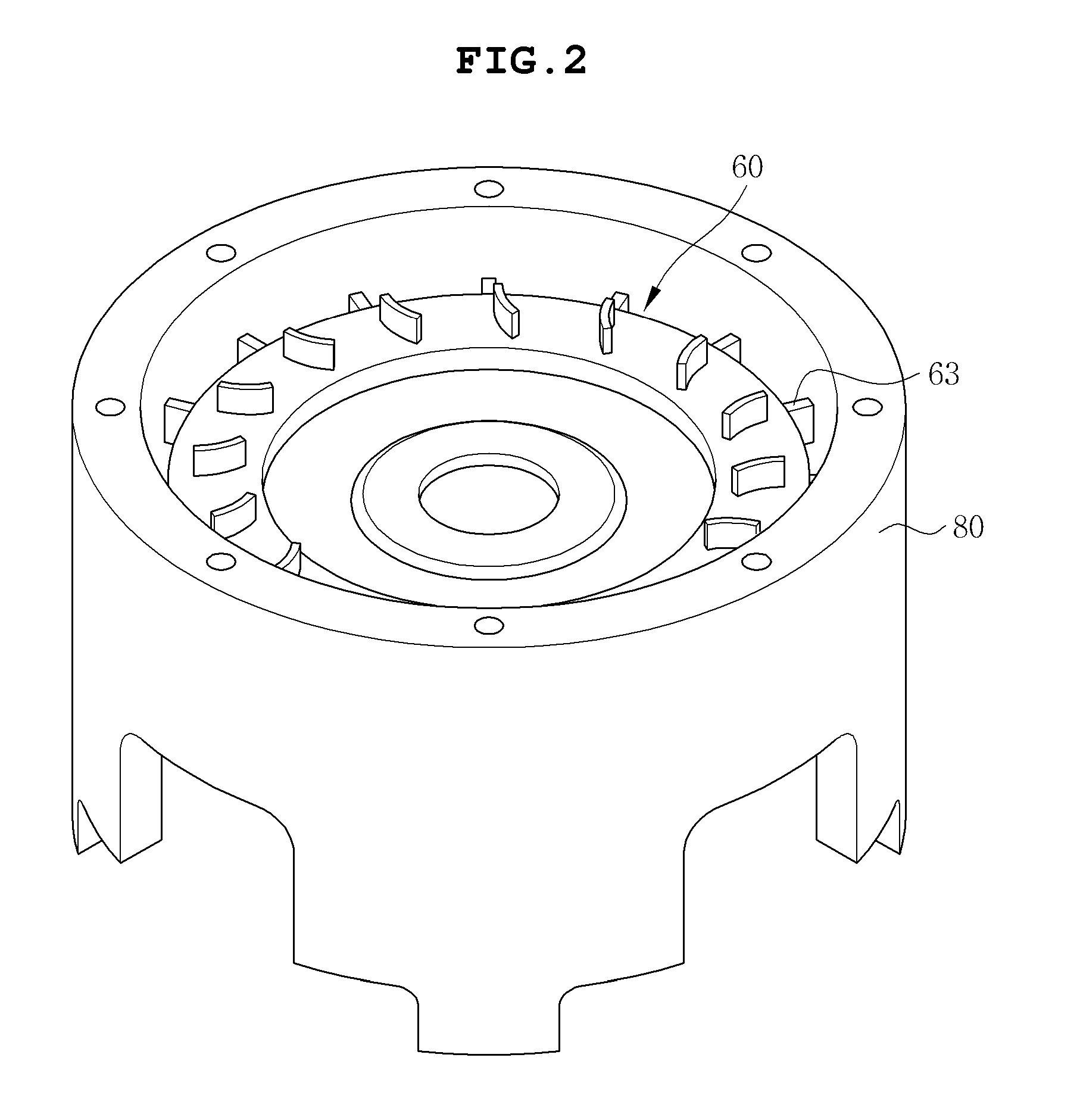

Switched reluctance motor assembly

InactiveUS20140056740A1Improve productivitySimple product structureEngine manufacturePump componentsEngineeringSwitched reluctance motor

Disclosed herein is a switched reluctance motor assembly capable of reducing an assembling error that is generated according to separate assembling and improving precision of assembling of bearing parts by forming a diffuser part and a motor housing integrally with each other. In the switched reluctance motor assembly, the diffuser is coupled integrally with the housing, such that a separate member for fixing the diffuser is omitted, thereby making it possible to reduce vibration according to driving of a motor and noise according to the vibration.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Crystal wafer testing method and structure of LED

ActiveCN1956159ATest large and fastQuick testSemiconductor/solid-state device testing/measurementSolid-state devicesLight-emitting diodeSemiconductor

A method for testing grade of chip on LED includes sticking an adhesive tape at back said chip, cutting it to be multiple LED chip with adhesive tape, contacting P type and N type of electrodes on those chips by detection card with multiple detection structures in ohm mode, setting a light detector on each of said detection structure, setting these light detector correspondingly above those chips and using them to detect light source emitted by those Led chips.

Owner:CHIPMOS TECH INC

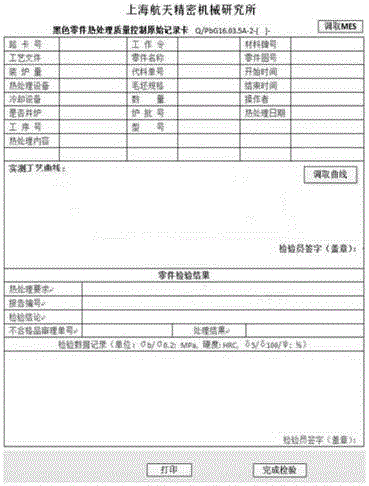

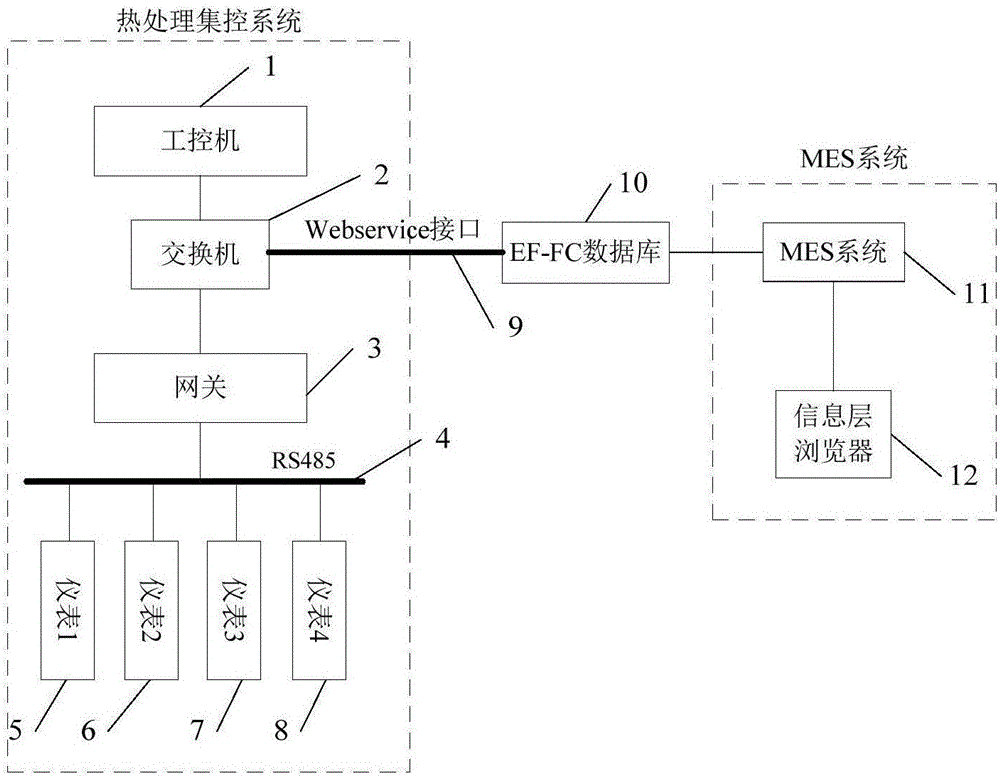

Intelligent heat treatment system based on MES and control method thereof

ActiveCN106774192ASimple product structureImprove management levelTotal factory controlProgramme total factory controlSystem integrationSystem configuration

The invention provides an intelligent heat treatment system based on MES and a control method thereof. The system comprises an industrial control computer, a switch, four sets of instruments, a Webservice interface, an EF-FC database and an MES system. A system integration mode is an intermediate file indirect (URL mode) integration mode, a system configuration mode is a B / S structure mode, a configuration scheme of an information integration platform based on intermediate file+ Webservice is employed, and the heat treatment system and the MES system are integrated. The system is advantaged in that disconnection between a heat treatment production process and the MES system can be made up, the field production process can be directly seen by a management level, field production data can be further effectively fed back to the management level, and scheduling in the heat treat process is convenient; workshop production structures are optimized, a workshop management level is effectively improved, and an establishment process of digital workshops is accelerated.

Owner:SHANGHAI SPACE PRECISION MACHINERY RES INST

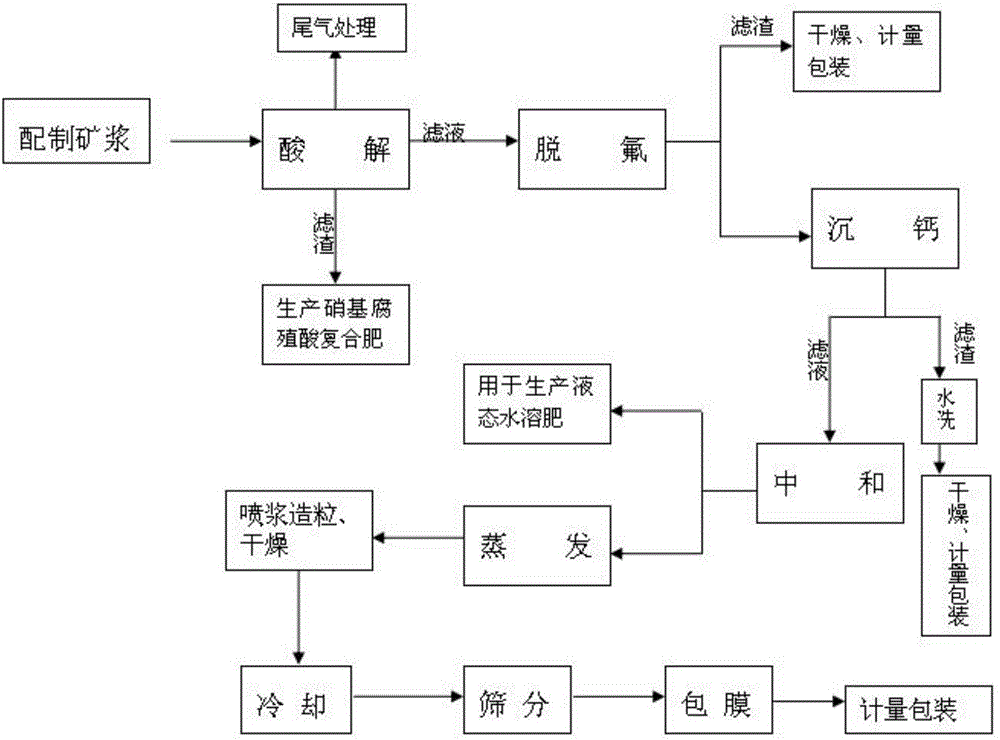

Method for co-production of chemical synthetic fertilizer by industrial calcium products

ActiveCN106517293ASimple product structureSimple structureCalcium/strontium/barium carbonatesCalcium/strontium/barium sulfatesChemical synthesisNitrohumic acid

The invention relates to a method for co-production of a chemical synthetic fertilizer by industrial calcium products, and belongs to the field of production of agricultural fertilizers. The method comprises the following steps: preparing phosphorite powder into ore pulp by using a raw material slurry method, reacting the ore pulp with nitric acid, and filtering; feeding filter residues to a compound fertilizer workshop to produce a nitrohumic acid compound fertilizer; adding sodium nitrate in the filtrate to remove fluoride; centrifugally dehydrating; drying the filter residues to prepare sodium fluosilicate; adding ammonium sulfate, potassium sulphate or potassium carbonate in the filtrate to deposit calcium; then filtering; preparing the industrial calcium products from the filter residues; and neutralizing, concentrating, guniting, drying, cooling, enveloping, metering and packing the filtrate to obtain the chemical synthetic fertilizer.

Owner:CHONGQING HUAQIANG ECOLOGICAL FERTILIZER IND CO LTD

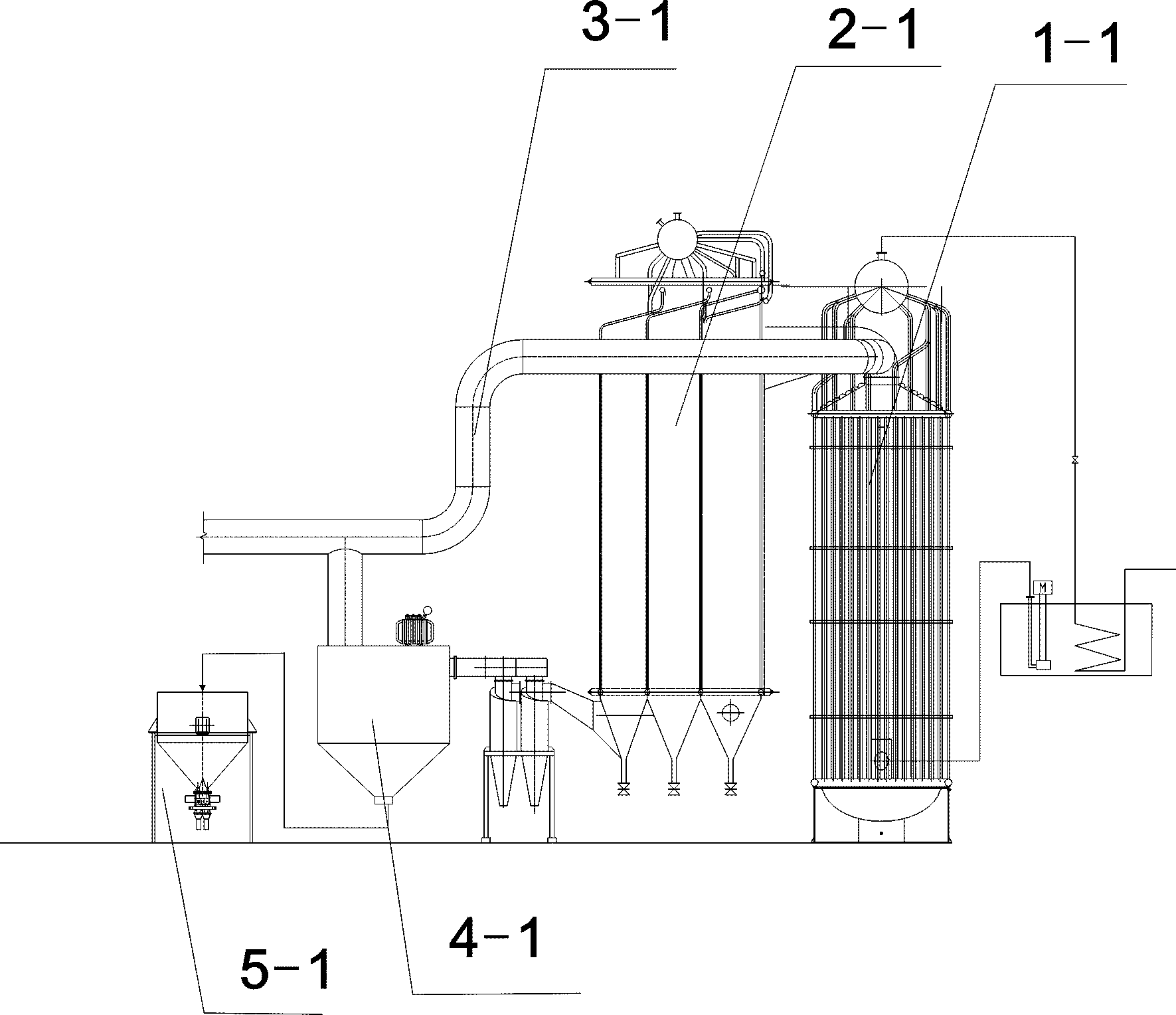

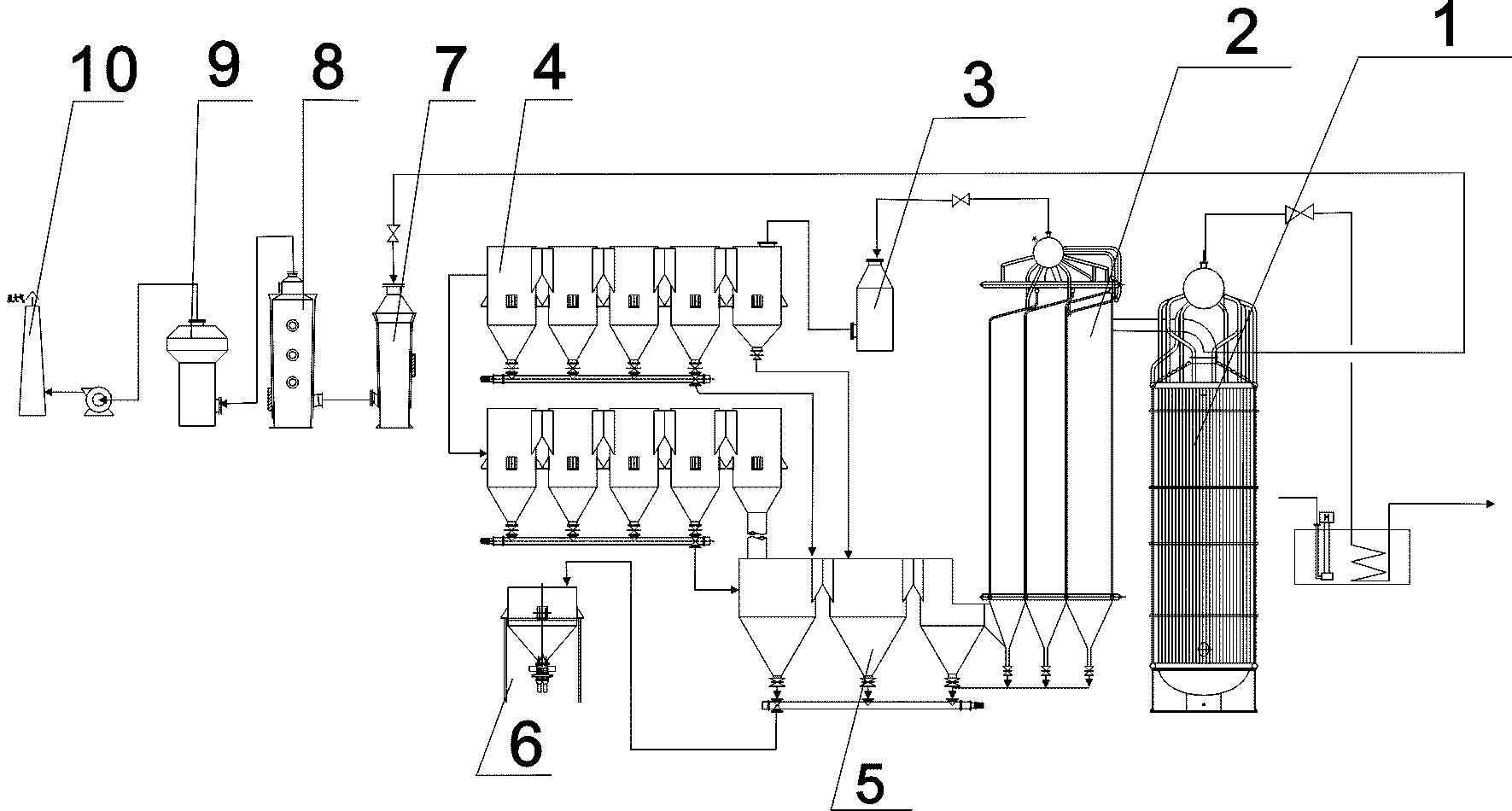

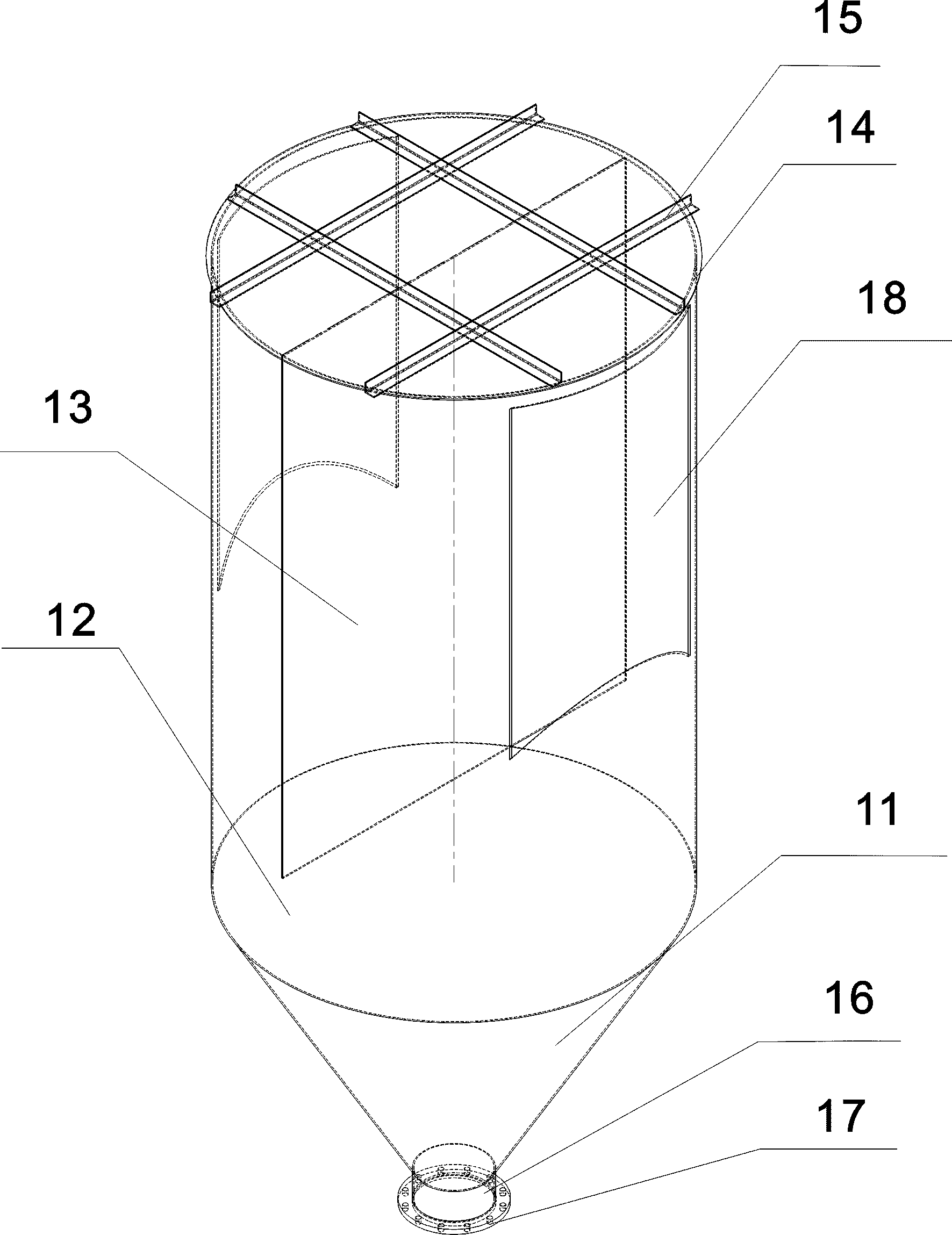

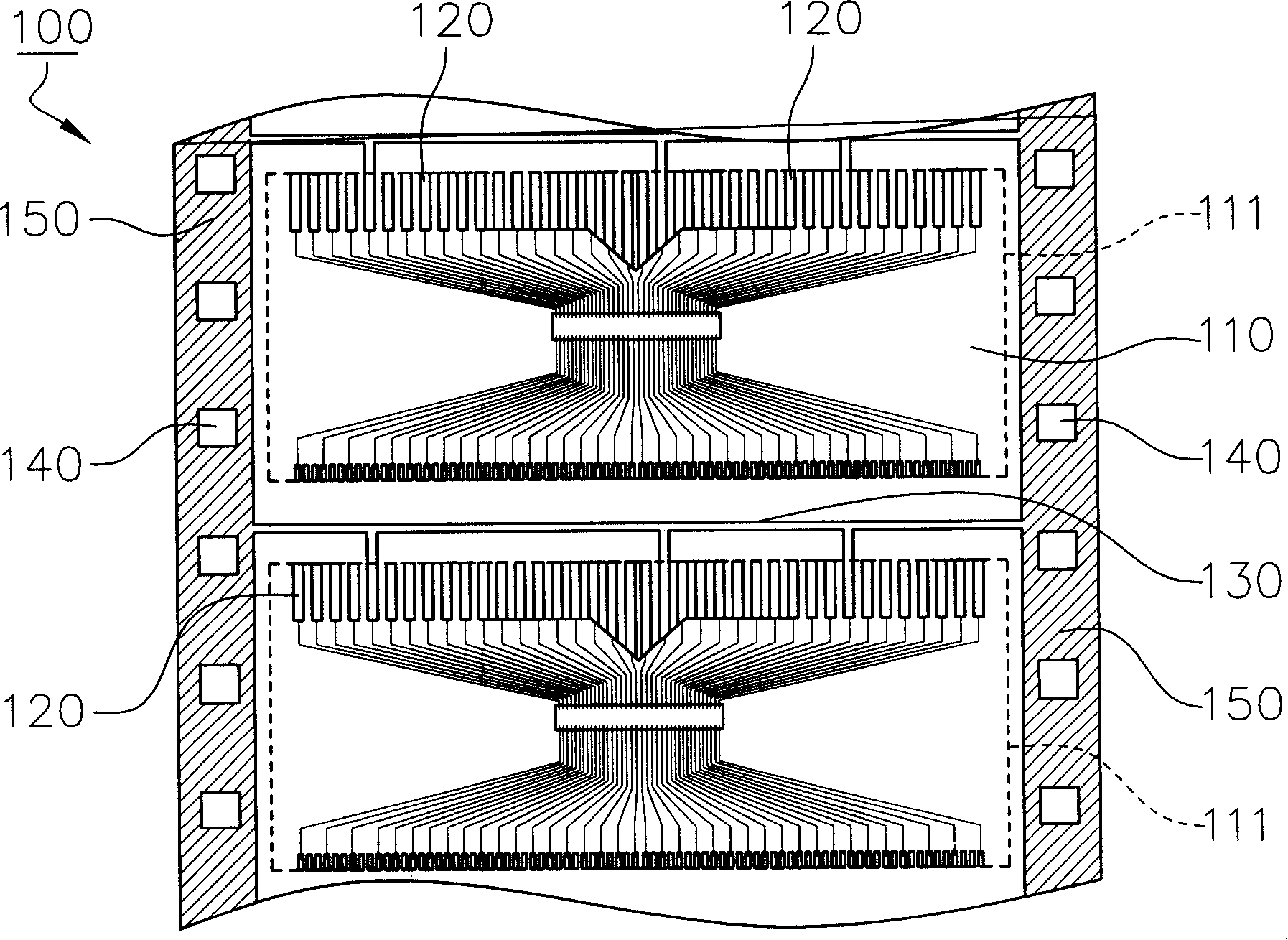

Process and device for selectively producing phosphorus pentoxide

InactiveCN103723695AReduce labor intensityEnter in timePhosphorus oxidesCondensed phosphoric acidsCombustionDesiccant

The invention discloses a process for selectively producing phosphorus pentoxide. By using yellow phosphorus as a basic material and sulfuric acid as a drying agent, the phosphorus pentoxide is prepared by combustion in a phosphorus combusting furnace, phosphorus pentoxide smoke prepared by combustion of the yellow phosphorus is introduced into a multistage sedimentation system after being cooled through a cooling system, and sent to a material collecting bin after being further cooled by the multistage sedimentation system to prepare phosphorus pentoxide powder, and a tail gas is exhausted after being purified; or the phosphorus pentoxide smoke prepared by combustion of the yellow phosphorus combustion is sequentially introduced into a polyphosphoric acid absorbing tower and a phosphoric acid absorbing tower for being absorbed after being cooled by the cooling system so that polyphosphoric acid and phosphoric acid are respectively obtained, and the tail gas is exhausted after being absorbed through a foam absorbing tower, an ammonia absorbing tower and a fiber demister. According to the process, equipment is capable of reasonably optimizing a structure of production equipment; the purity of the produced phosphorus pentoxide reaches above 99.5 percent, and the phosphorus pentoxide can be largely produced.

Owner:HUBEI LIUSHUGOU CHEM TECH

Semiconductor package substrate increasing static dissipation capability

InactiveCN101226919AIncrease dissipation areaEnhanced Static Dissipative CapabilitySemiconductor/solid-state device detailsSolid-state devicesSolder maskSemiconductor package

The invention relates to a semiconductor package substrate capable of reinforcing static dissipating ability, comprising a dielectric layer, a plurality of pins, a plurality of first static guide circuits, a plurality of second guide circuits and a solder mask. The first static guide circuits and the second static circuits are formed in a plurality of static dissipating areas of the dielectric layer, the static dissipating areas are in electric insulating neighbored arrangement and are exposed out of the solder mast, further the first static guide circuits are connected with a part of pins, thereby reinforcing the static dissipating ability of the substrate in manufacture procedure.

Owner:CHIPMOS TECH INC

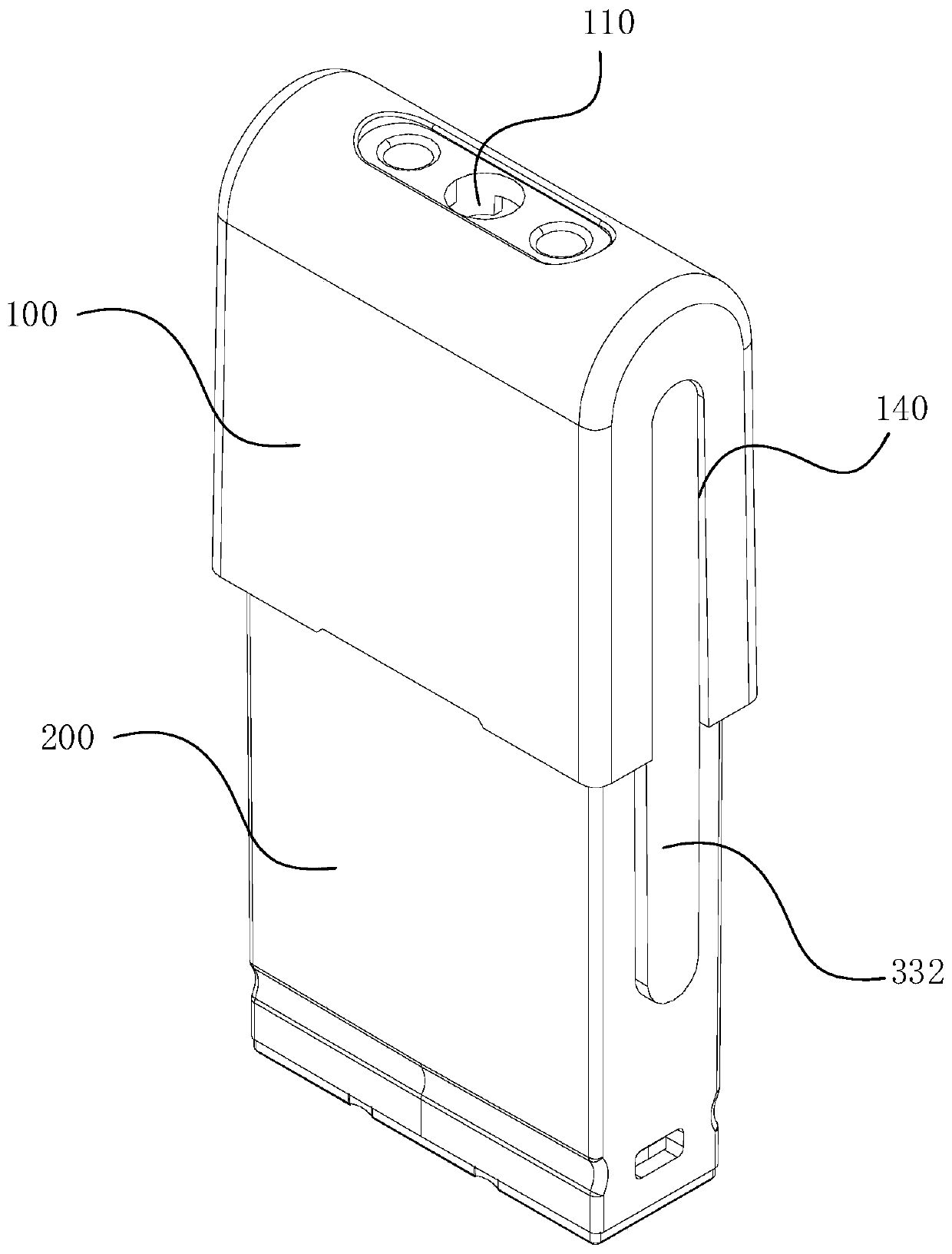

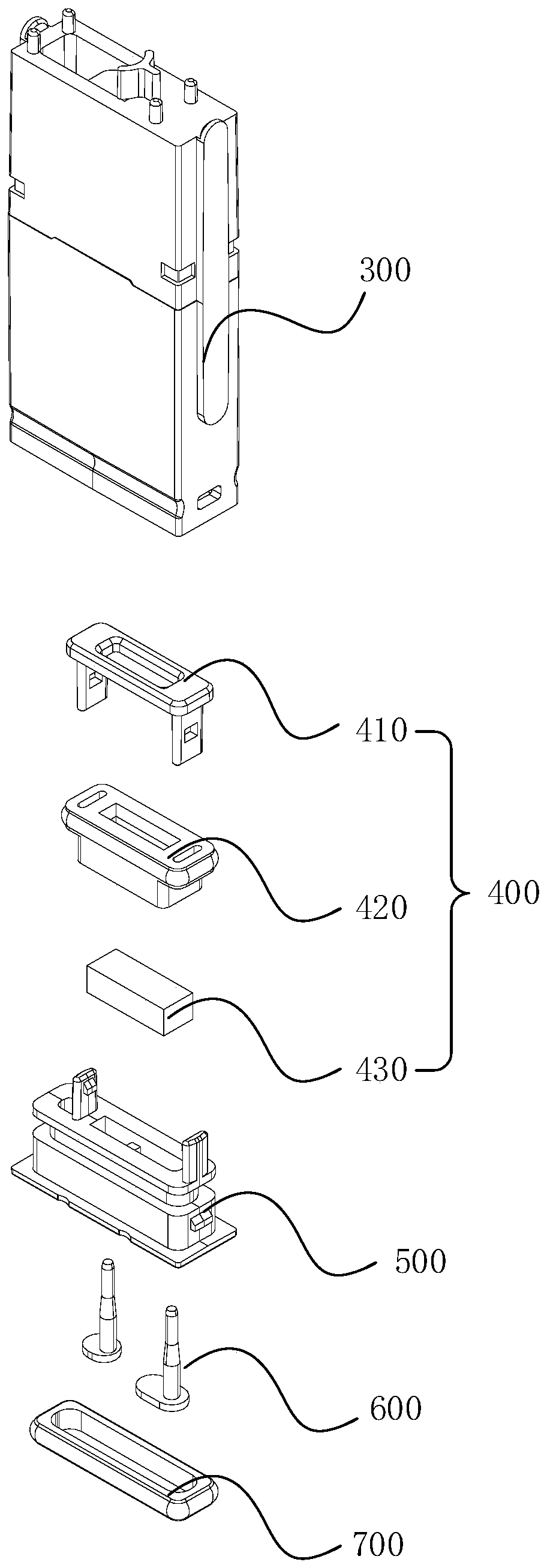

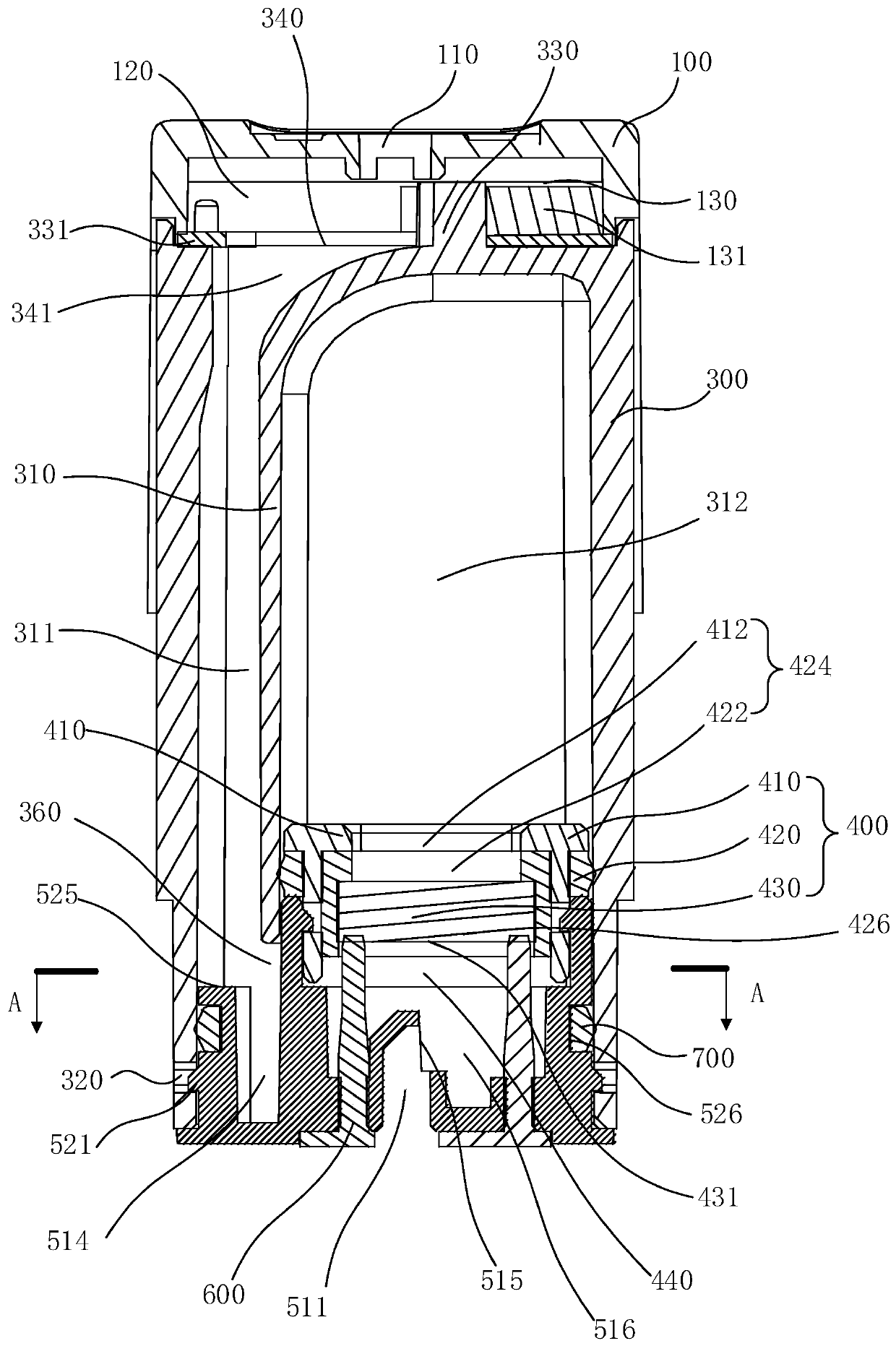

Electronic cigarette and atomization device thereof

The invention relates to an electronic cigarette and an atomization device thereof. The atomization device comprises a shell, an atomization assembly and a fixed base. An air outlet channel and a liquid storage bin are arranged in the shell; the fixed base is fixedly connected with the shell; the atomization assembly arranged in shell comprises a liquid guide piece, a fixed support and a sleeve body, a heating piece is arranged on the liquid guide piece, the sleeve body is connected with the liquid guide piece and the heating piece in a sleeved mode, and the fixed support is connected with thesleeve body and the fixed base in a clamped mode; an atomization cavity is formed between the atomization assembly and the fixed base, and the atomization cavity is communicated with the liquid storage bin and the air outlet channel. According to the electronic cigarette and the atomization device thereof, the structure of the atomization assembly is reasonably arranged, and the atomization assembly matches the shell and the fixed base, so that the whole atomization device can be made thinner; the product structure is more simplified, and assembly or assembly is facilitated.

Owner:SHENZHEN HANGSEN STAR TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com