Automobile chip wide domain oxygen sensor using standard signal output

A vehicle-used oxygen sensor and standard signal technology, which is applied in the field of auto parts, can solve the problems of difficult to guarantee the service life of the oxygen sensor, increase the maintenance and replacement cost of users, and reduce the control accuracy of EFI, so as to achieve the reduction of the number of bonding layers and high temperature resistance. Improved burst performance, reduced interference effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

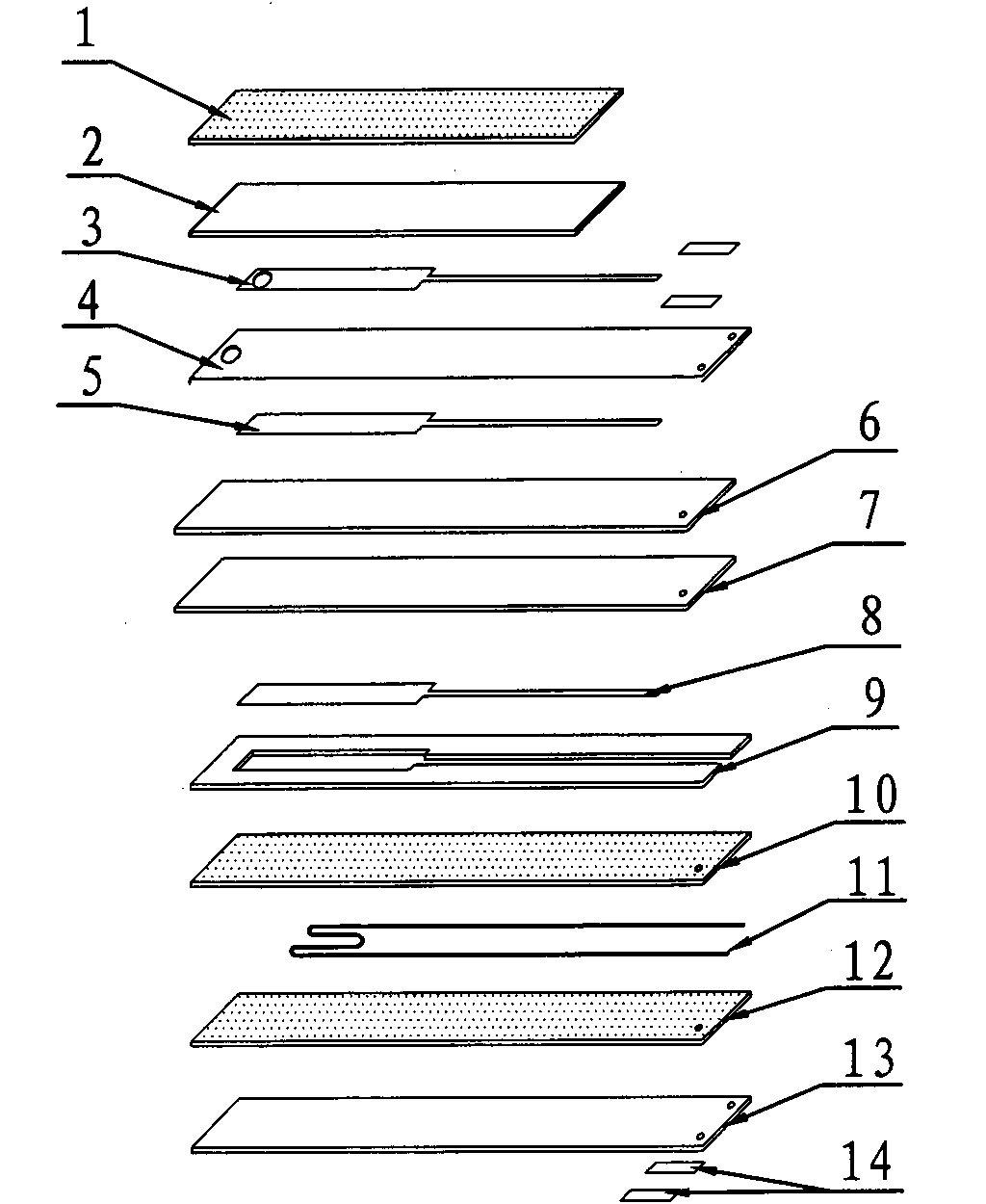

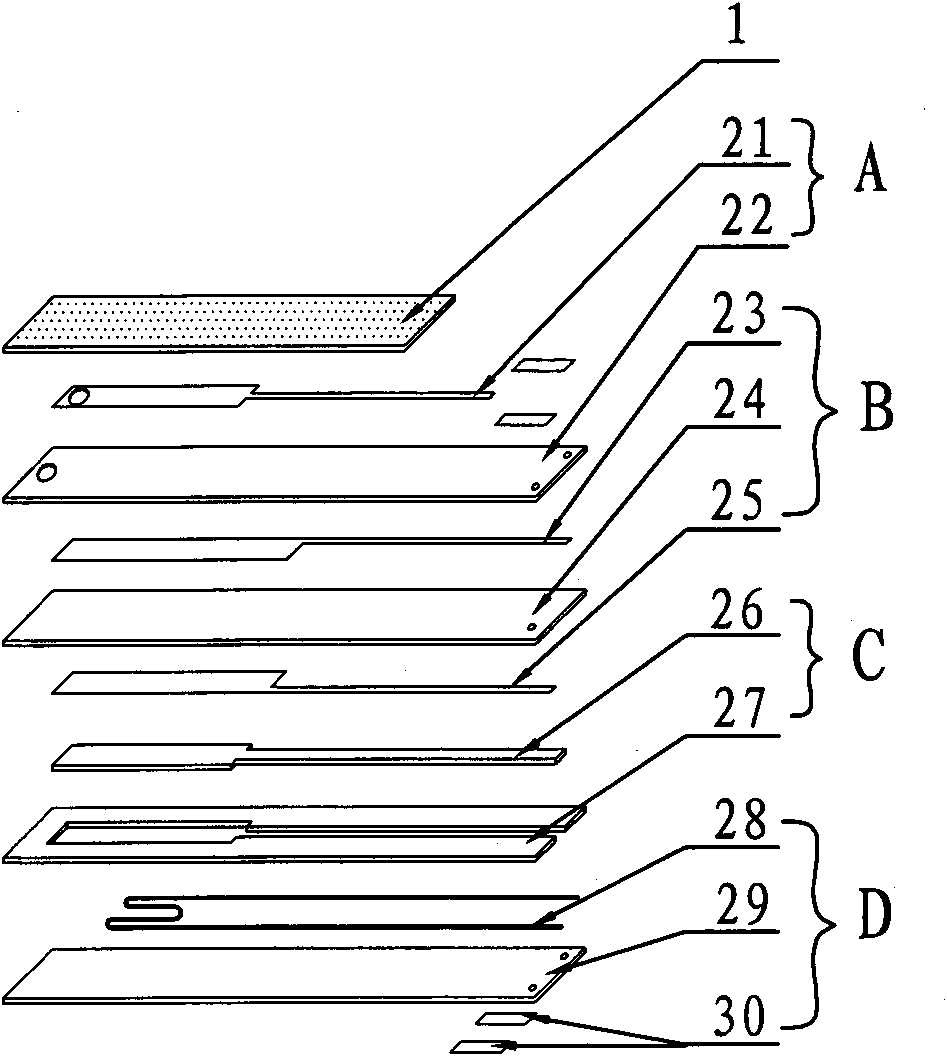

[0019] The chip type wide-area standard signal output vehicle oxygen sensor, such as figure 2 As shown, it consists of a porous protective layer 1, an oxygen pump outer electrode 21, an oxygen pump substrate layer 22, an oxygen pump inner electrode 23, a reaction substrate layer 24, an inner reaction electrode layer 25, and a multilayer ceramic gas exchange layer from top to bottom. 26. The upper heating substrate layer 27, the heating electrode layer 28, the lower heating substrate layer 29 and the heating electrode pin 30 are composed. The porous protective layer 1 is a porous ceramic protective layer made of alumina; the oxygen pump substrate layer 22 is made of oxide The yttrium-stabilized zirconia powder is made into a substrate. On this substrate, the outer electrode 21 of the oxygen pump is printed with platinum paste, and the two form the first layer of sheet A; the reaction matrix layer 24 is made of yttrium-stabilized zirconia. The substrate made of powder is printe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com