Ignition gun for industrial combustor

A burner and ignition gun technology, which is applied in the directions of combustion ignition, combustion method, and ignition using electric sparks, to achieve the effect of simplifying product structure, ensuring delivery quality, and improving work reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

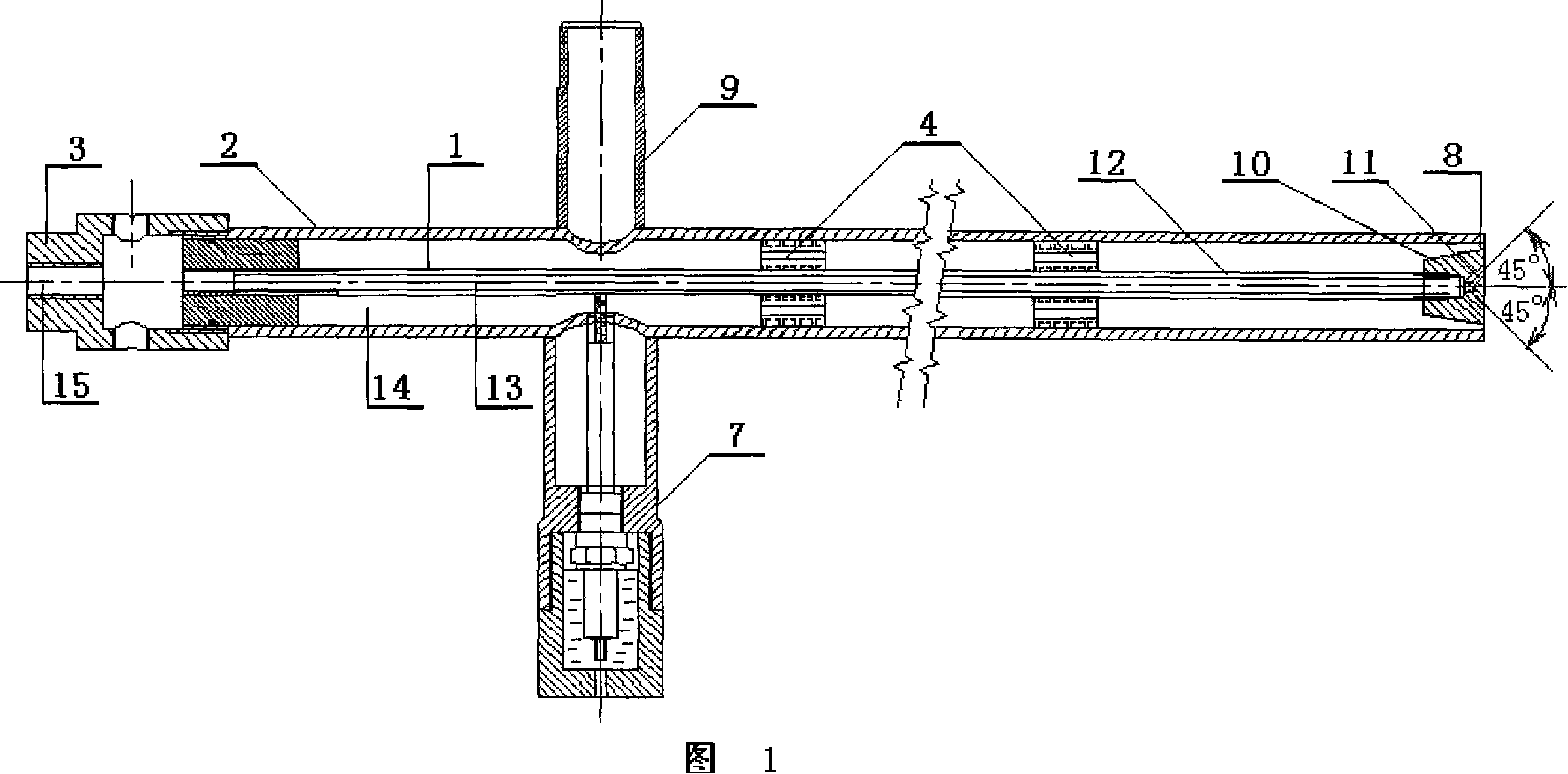

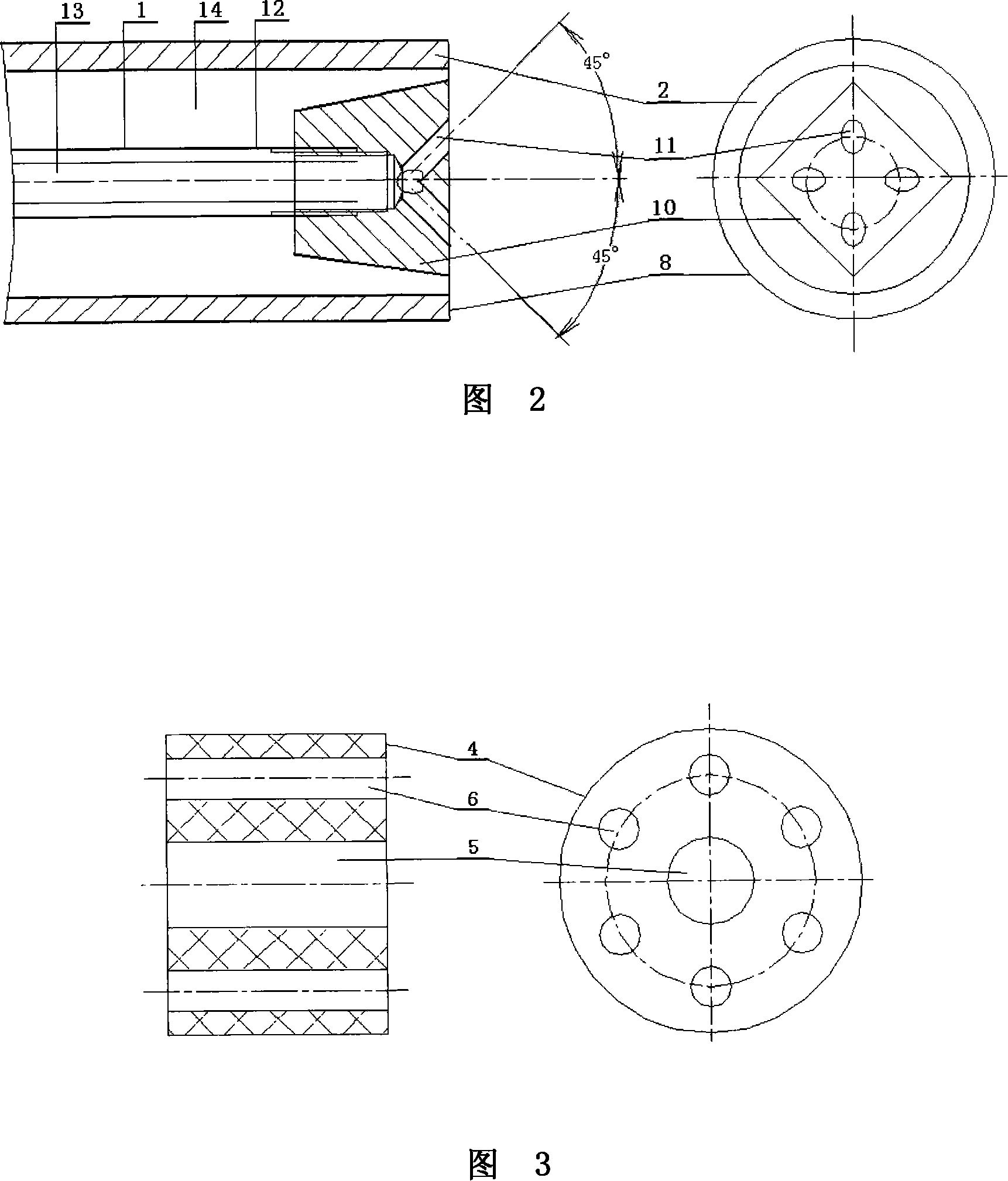

[0019] The present invention will be further described below in conjunction with the accompanying drawings and typical embodiments.

[0020] In Fig. 1, Fig. 2 and Fig. 3, the main body of the industrial burner ignition gun of the present invention includes a central tube 1, an outer casing 2, an ignition electrode, a high-voltage wire, a transition piece 3 and an insulating support 4, wherein: the insulating support 4 It is made of polytetrafluoroethylene, with a central installation hole 5 and an airflow hole 6; the central tube 1 is made of stainless steel, and its tube wall 12 is electrically connected with the ignition high-voltage generating device 7, and the front end is provided with a belt ignition gun The ignition electrode of the head 8 is provided with 4 inclined spray holes 11 inclined at 45° and diverging from the center to the outside on the nozzle block 10 of the ignition gun head; There is a combustion-supporting air inlet pipe 9; the transition piece 3 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com