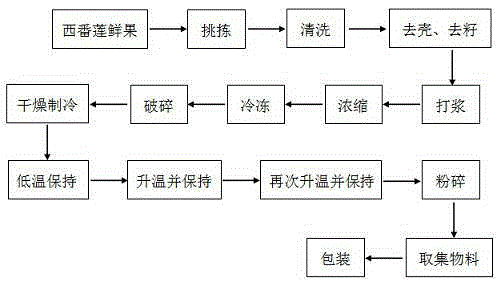

Technology for preparing fruit juice powder from passion fruits as raw materials

A technology for fresh passion fruit and fruit juice powder, applied in the field of food processing, can solve problems such as difficulty in maintaining the flavor of passion fruit, inconvenience in transportation, inconvenience in use, and inability to artificially imitate the aroma, and achieves easy portability and transportation, light weight, and ease of use. Simple and convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The freeze-drying processing technology provided by the present invention is to adopt the fresh passion fruit of moderate maturity, no damage by diseases and insect pests, and no rot as raw material, and obtain the passion fruit puree after the selected and cleaned passion fruit is shelled and deseeded, and separated The fruit seed obtains passion fruit juice 100kg, soluble solid content 12.3°Bx, freezes and concentrates to 43.2Bx° thick sauce, and thick sauce is frozen to -50 ℃, after all thick sauce is frozen, enter crusher to crush, and make particle diameter less than 3mm, put it into the drying oven. The pressure in the drying box was set at 8.0 Pa, frozen to -29°C and kept at the temperature for 3 hours. Then heat, the temperature gradually rises to 27°C, keeps for 1h, then heats up to 50°C and keeps for 10 minutes, opens the drying box to collect the materials, and pulverizes them with a jet mill to obtain 10.7kg of freeze-dried fruit powder with a moisture conte...

Embodiment 2

[0025] The freeze-drying processing technology provided by the present invention is to adopt the fresh passion fruit of moderate maturity, no damage by diseases and insect pests, and no rot as raw material, and obtain the passion fruit puree after the selected and cleaned passion fruit is shelled and deseeded, and separated The fruit seed obtains 200kg of passion fruit juice, soluble solids 12°Bx, freezes and concentrates to 55.6Bx° thick sauce, and the thick sauce is frozen to -60°C, and when all the thick sauce is frozen, enter the crusher to crush, so that the particle diameter is less than 3mm, put it into the drying oven. The pressure in the drying box was set at 10.7 Pa, frozen to -23°C and kept at the temperature for 6 hours. Then heat, the temperature gradually rises to 27°C, keep for 2h, and finally the product is kept at 60°C for 25 minutes, open the drying box to collect the material, and then crush it with a jet mill to obtain 20.1kg of freeze-dried fruit powder wi...

Embodiment 3

[0027] The freeze-drying processing technology provided by the present invention adopts the fresh passion fruit of moderate maturity, no damage by diseases and insect pests, and no rot as raw material. Passiflora juice obtained from fruit seeds is 100kg, soluble solids 11.9°Bx, frozen and concentrated to 41.2Bx° thick sauce, the thick sauce is frozen to -50°C, and after all the thick sauce is frozen, it enters the crusher for crushing, so that the particle diameter If it is less than 3mm, put it into the drying oven. The pressure in the drying box was set at 8.0 Pa, frozen to a temperature of -23° C., and kept for 4.5 hours. Then heat to make the temperature gradually rise to 27°C, keep for 1.5h, continue to heat up to 60°C and keep for 15 minutes, open the drying box to collect the materials, and then pulverize with a jet mill to obtain passion fruit with a moisture content of 4.1%. Freeze-dry the original powder 9.8kg, then pack in an environment with humidity less than 30%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com